Ayco – Project Oak

629 Columbia Street Ext. Cohoes, NY 12047

Consigli Project # 527

Emergency Response Plan

ALL EMERGENCIES SHOULD BE REPORTED BY CALLING 911

In the event of an emergency the following policy will be adhered to for the safe evacuation of the Project. An immediate call will be made to Emergency 911. Project information for the call is The Ayco Building Project, 629 Columbia Street Ext. Cohoes, NY 12047

A Consigli project representative will be dispatched to the front of the building to meet the responding Emergency Personnel and advise the individual in charge of the location of any chemicals or hazardous substances that may be present on any of the building floors or storage facilities on site. SDS’s will be readily available if needed by Fire Dept. In the event of a serious injury requiring the assistance of EMS the injured worker will be kept as comfortable as possible. Emergency first aid if necessary will be administered. Under no circumstances will the injured person be moved unless the worker’s life is in danger because of fire or calamity. A worker will be assigned to meet the medical personnel to direct them to the location of incident.

In the event an evacuation is required, all personnel at this job site will assemble at the muster point (see separate evacuation plan). The foreman for each subcontractor company will meet at that location and take a count of their staff. If for some reason a worker is unaccounted for, the fire department will be notified of the last location where the worker was observed.

**List of First Aid-CPR trained personnel will be compiled and posted in the project office and in this site specific Safety and Health Plan.**

Consigli Construction Co. Inc.

| Jennifer Rand Position:Project Executive E-mail jrand@consigli.com Cell (774)573-9451 Jose Javier Ayala |

Chris Parrott |

| Edwin Robinson Position: Regional Safety Manager E-mail erobinson@consigli.com Cell (845)518-4897 |

Carly Cunningham Position: Project Engineer Email ccunningham@consigli.com Cell (518)530-6453 |

Memo from the President

FROM: Greg Burns, President

TO: Employees and Subcontractors

SUBJECT: Job Safety

Over the past several years we have made significant improvements to our occupational health and safety program. These improvements have resulted in fewer employee injuries, fewer OSHA citations and an exemplary safety image within the construction industry. Through the combined efforts of our staff and employees we have become more competitive and in turn, we have provided more jobs for all our employees.

As employees and subcontractors to Consigli Construction, you represent all of us in the workplace and we need your pro-active support to continue making safety improvements and continue expanding our market share. Therefore, we are asking all employees and subcontractors to read, understand and practice the enclosed Health and Safety principles and guidelines. This means routinely training employees, conducting weekly toolbox meetings, wearing appropriate personal protective equipment, using fall protection when necessary and practicing all other safety-related items listed in the Safety and Health Handbook. Even more importantly it means developing a safety-conscious attitude.

We take safety very seriously and we expect you to do the same. If you have any questions, call me or ask the Site Superintendent at your worksite.

Thank you,

SITE INFORMATION

This Emergency Response Plan (E.R.P.) is specifically developed for Consigli work associated with The Ayco Project.

SITE LOCATION

The construction site is located at 629 Columbia Street Ext., Cohoes, NY 12047 The location for the project field office is currently at the Project jobsite (notifications of any changes will be provided). When determined, the field office will become the Emergency Operations Center (EOC).

EMERGENCY TYPE

The following situations are considered emergency response actions and should be handled in accordance with the procedures outlined in this plan.

- Serious Injury/Fatalities

- Fire/Explosion

- Structural Damage/Collapse

- Weather or Geological Event

- Environmental Incident

- Traffic Disruption

- Utility Damage

- Illegal Activity

- Labor Problems

- Bomb Threats/Military Ordinance Unearthing

- Acts of Terrorism

WHEN REPORTING AN EMERGENCY, PLEASE PROVIDE THE FOLLOWING:

- Your location, phone number, and name;

- The location of the site and incident (building name, floor and room number);

- Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

- The safest route to the incident

CRISIS RESPONSE PROTOCOL:

- Attend to the injured

- Contact 911

- Immediately contact Edwin Robinson (Safety Manager) (845)518-4897

- Immediately Contact LeChase Project Team. (If contractually still on site).

- Post person at front gate, only allow access to emergency responders

- Record names/addresses of witnesses

- Do not allow media on site.

- Refer all media inquiries to home office (Project Specific Crisis Management Cards will be designed and disseminated to project personnel)

The following is a list of the Chain of Command/Call Hierarchy on the project for establishing lines of succession during communication involving all emergencies.

Back– End of Emergency Response Plan

Emergency Contact Names and Numbers

First call: 911

Consigli Superintendent: Jose Javier Ayala (774)217-8229

Consigli Regional Safety MNG: Edwin Robinson (845)518-4897

Consigli PX : Jennifer Rand (774)573-9451

Consigli PM: Chris Parrott (845)750-0236

Project Engineer: Carly Cunningham (518)530-6453

NOTE: If Consigli Regional Safety Manager is not available or unreachable Contact Sean Hynes, General Superintendent. (845) 902-8395

EMERGENCY MANAGEMENT RESPONSE: In the event of an Emergency the construction workers shall leave the building immediately and proceed to the muster point indicated in the evacuation plan. In the Event of a DISASTER, the Superintendent or Safety director shall instruct the construction workers to leave the site or remain in place and await further instruction. The following steps should be taken in the event of an emergency.

Back– End of Emergency Contact Names and Numbers

Medical Facilities

|

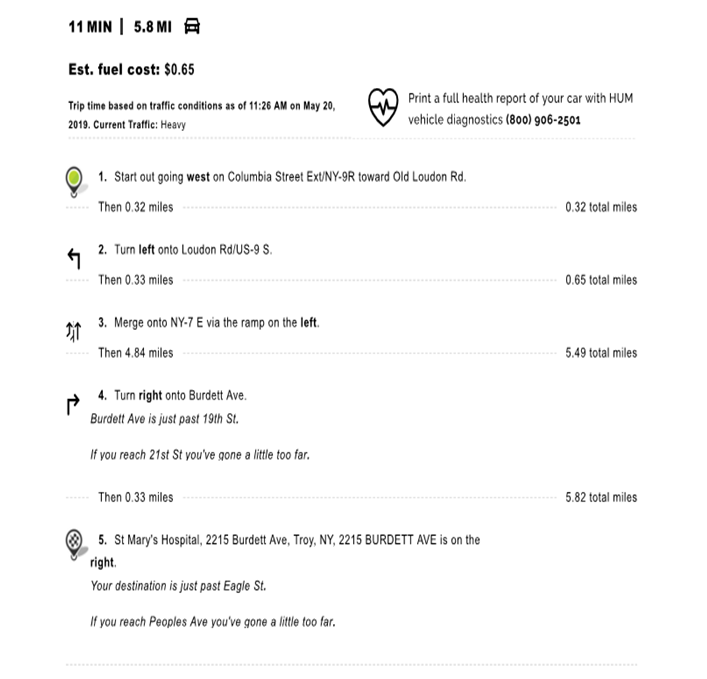

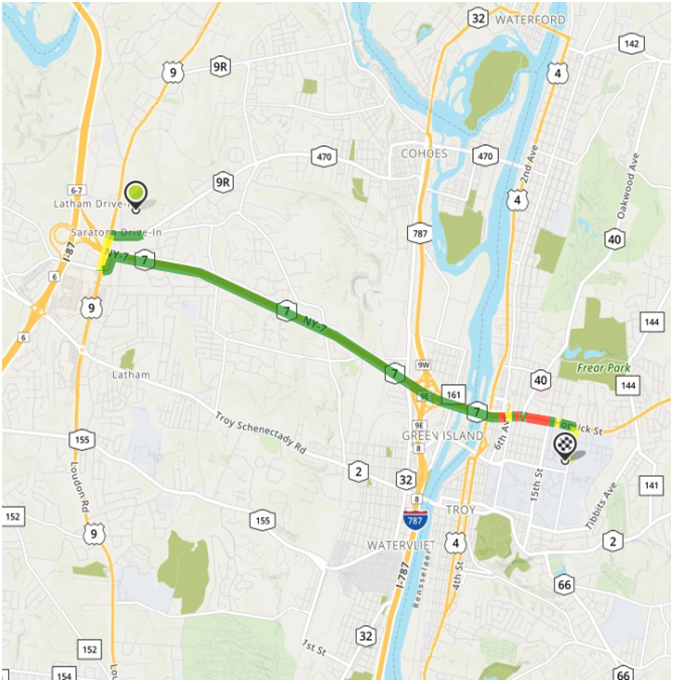

DIRECTIONS TO ST. MARY’S HOSPITAL FROM AYCO PROJECT SITE |

BACKGROUND OF THE PROJECT: The 150,000-square-foot Ayco Building is located in Latham, New York off the Northway exit 7. The new LEED-certified building will be four stories and include a cafeteria, meeting spaces, day care, bank and a small retail plaza.

Back– End of Medical Facilities

Site Safety Plan

BRIEF SCOPE OF PROPOSED WORK:

- Interior Framing & Drywall

- MEP Systems

- Acoustical Ceilings

- Interior Flooring

- Demountable Partitions

- Wall Finishes

S.A.F.E.: STAYING ACCIDENT FREE EVERY DAY

S.A.F.E is the Safety Mission that forms the very foundation of the Consigli Safety Culture. The S.A.F.E. mission, which is supported by technology, (Predictive Solutions internal auditing instrument which identifies and defines leading indicator related information); Leadership (Empowering our team members to assure safe projects); Humanization (Protect the ones you love by protecting yourself); Jobsite Gym (Morning warm-ups, stretch and flex); Training (Integrating sub-contractors into the Consigli Safety Culture); and Lean (nothing hit the ground), is the driving force behind Consigli’ s drive to our vision – ZERO. ZERO is the philosophy that all accidents are preventable and that no accident is acceptable. The S.A.F.E. mission is the guiding force to achieving the Consigli Safety Vision which is ZERO.

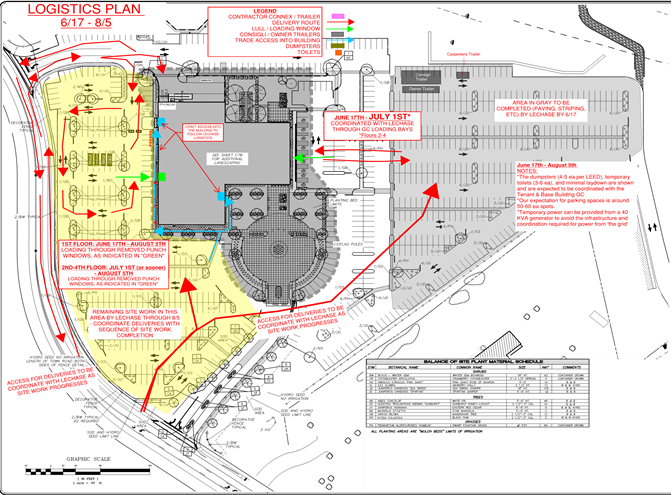

IDENTIFY THE SPECIFIC ROUTE IN AND OUT OF THE CONSTRUCTION SITE (TRAFFIC MANAGEMENT): The attached proposed construction logistic plan is designed to isolate construction activity from the surrounding building/commercial district and while providing safe access for pedestrians and vehicles during normal day to day activities and / or emergencies at the Ayco project. All scheduled deliveries must be scheduled with Consigli’s project superintendent who shall upon approval of deliveries will direct such deliveries to the south gate of the project site off Columbia Street Ext.

Precast “Tire Wash Racks” will be installed on all gates to ensure excessive tire pickup shall be minimized during daily heavy construction traffic operations.

EXPOSURE TO STREET TRAFFIC: All deliveries as stated above will be made at the designated areas unless otherwise directed by Consigli Superintendent or by LeChase Construction where contractually related. There may be exposure to live vehicular traffic and police details may be used as needed. All speed limits will be obeyed and deliveries will be made as to coincide with working hours. All traffic control signage will meet NYSDOT requirements before being installed. Fire dept. access will be maintained and kept open for emergency responders. Construction signage (When Consigli acquires site control) shall be erected along access routes of Columbia Street Ext. which shall provide detailed directions to gates designated for use as well as speed restrictions. All signage detailed on the Ayco projects logistics plan is subject to change upon Consigli Project Team/LeChase Construction approval and/or until LeChase has concluded their Contractual obligations to the owner and has then turned over site control to Consigli Construction.

ACTIVITY SAFETY ANALYSIS (ASA)/JOB SAFETY ANALYSIS (JSA): An ASA/JSA depending on Severity of hazard shall be conducted for each identifiable feature of work to be performed. The ASA/JSA shall be reviewed each week with each subcontractor by Consigli superintendent/supervisor. ASA/JSA shall be reviewed weekly, signed by all workers including their supervisor, with all involved personnel performing that particular task. At no time is a subcontractor and subcontractor worker to perform any work without a drafted ASA/JSA in place and reviewed by all workers performing the work. Workers signature on all ASA’s and JSA’s ensures that communication of the assessed hazardous conditions and methods designed to mitigate such conditions has taken place by the subcontractor supervisor.

SUBSTANCE ABUSE

The use, possession, concealment, transportation, promotion, or sale of any of the following substances will be grounds for disciplinary action, up to and including termination from employment on said project.

- Alcoholic beverages

- Marijuana and other illegal drugs, look-a-like, and designer drugs

- Drug paraphernalia

- Controlled substances such as medication when usage is abused or when the substance is possessed without proper prescription labeling

WEAPONS AND CONTROLLED ITEMS

The use, possession, concealment, transportation, promotion, or sale of any of the following controlled items will be grounds for disciplinary action, up to and including termination from employment on said project.

- Firearms, weapons, and ammunition

- Unauthorized explosives including fireworks

- Stolen property or contraband

HARASSMENT

We expect all individuals to treat each other with respect. We are committed to maintaining an environment in which employees and visitors are not subjected to different treatments because of legally protected characteristics. Therefore, we will not accept or tolerate any discrimination, different treatment or harassment of or among employees, customers, suppliers, students, faculty or visitors based upon the following characteristics:

- Age

- Disability

- Sex (including pregnancy)

- Race

- Nationality

- Religion

- Color

- Sexual orientation

WORKPLACE VIOLENCE

- There will be a ZERO tolerance policy in effect for any workplace violence event matching the aforementioned behaviors.

- Any act or threat of physical violence, harassment, intimidation, or other threatening disruptive behavior that occurs at the project is to be reported to the Consigli Project Superintendent immediately.

- Call to be made to Consigli Regional Safety Manager and General Superintendent.

- Investigation by Consigli Superintendent shall happen immediately.

- Conflicting parties to be separated and placed into 2 separate locations and interviewed by Consigli Superintendent as to facts alleged.

- Witnesses’ to be identified and statements taken.

- Upon investigation – if physical assault or threatened physical assault took place – Business Agent shall be contacted immediately, individuals removed pending investigation outcome, and if necessary, contact Police.

- Complete Consigli “Workplace Violence Investigation Document” (APPENDIX KK) and forward to Regional Safety Manager and Corporate Safety Director. Any act or threat of physical violence, harassment, intimidation, or other threatening disruptive behavior that occurs at the work site is grounds for immediate dismissal from the project.

Management and Control: Incident investigation training will be conducted with all field operations and project management personnel. They will be schooled in the who, what, where, why and when method utilized in obtaining factual information with root cause analysis training necessary in determining primary and secondary incident causation. An examination in management failure causation will be stressed.

** Please review chapter 9 of Consigli’s Safety and Health Program for additional details **

MINIMUM PPE REQUIREMENTS

Project Superintendents shall be responsible for assuring that all workers on the Ayco project comply with the Personal Protective Equipment requirements. The Regional Safety Manager will periodically audit for field compliance. The Minimum Personal Protective Equipment requirements are as follows:

- All workers will be thoroughly indoctrinated by their respective employer and trained in the proper use of required protective equipment. Defective or unacceptable PPE will be removed immediately from service

- The Ayco project shall be a Mandatory Hard Hat Job.

- All workers will require 100% eye protection. All overhead work will require the use of either a face shield or pair of goggles in conjunction with safety glasses.

- All workers are required to wear gloves that are appropriate to the material manipulating task. Exceptions include lunch, restroom breaks, and office work. In addition to utilizing gloves, the subcontractor employer shall be responsible for training workers into proper use and limitations of the gloves utilized.

- Shirts with 4” minimum sleeve length.

- Subcontractors JSA’s need to document hand and finger hazards, and glove selection and use for protecting against said hazard.

- Employees shall be provided with face protection equipment when power tools, machines or operations present potential eye or face injury from physical, chemical, or radiation agents.

- Hearing protection against the effects of noise exposure shall be worn when sound levels exceed 85 dba as calculated by the Safety Manager on site. Each subcontractor supervisor shall make available at all times, the proper hearing protection for each worker.

- Respirators/nuisance masks, when needed for sweeping or other dusty conditions are to be provided by each subcontractor supervisor under the OHSA regulation 1910.134 for voluntary use only.

- Impermeable rubber or any impenetrable protection shall be worn to prevent skin contact with any acid, chemical, creosote, coal tar, fuel oil or concrete. This is especially true for Concrete workers and masons.

- 100% High visibility vests shall be worn by workers at all times.

- Metatarsal guards will be used by workers handling pneumatic tools, pipe, stone, timber and plate vibrators.

- Non-skid soles will be worn on safety shoes.

- Long pants are required at all times while on site. They shall be appropriate to the task being performed. Examples of acceptable pants include denim jeans, khakis, twill pants, or work pants. Examples of unacceptable pants include, but are not limited to sweat pants, nylon jogging/wind pants, pajama pants, flannel pants, etc.

- IMPORTANT NOTE: Personnel protective equipment for visitors shall include hard hats, high visibility vest and safety glasses as required.

PPE Training: Necessity, use, limitations, care and maintenance of all provided PPE by a subcontractor supervisor will be conducted upon issue. Said training is to be documented as part of the subcontractors toolbox talk meeting process. Retraining of employees by the subcontractor supervisor shall be conducted anytime site conditions change, PPE requirements change, or employee demonstrates improper use or lack of knowledge.

Personal protective equipment, which has been changed in any manner so as to reduce its effectiveness, shall be repossessed, repaired or destroyed. Personal protective equipment worn or used previously by a worker shall not be issued to another employee until the article has been cleaned and sterilized.

EXCAVATIONS: Excavation work (if applicable to the Ayco project) will incorporate some extremely deep excavations for installation of new underground infrastructure.

- Excavations 20’ or greater shall be identified in advance and have engineering approval for the means and methods of providing proper excavation protection for all workers scheduled to perform work within.

- All excavation work 5’ or greater will require planning and protection by the site subcontractor’s competent person and access protection to excavation when excavation cut is 4’ or greater.

- Erosion control will be required that will include existing tree protection, existing grounds repair following construction and street sweeping of earth materials displaced outside the work area for the duration of the project.

- Although most of the excavation work will take place within the Ayco project designated site area, additional roadway work outside the project site is expected. Consigli’s site superintendent shall coordinate and manage all roadway and site tie-in infrastructures outside the project designated site area. All work performed within right away of Columbia Street Ext. shall be performed in accordance with all NYS DOT roadway work permit requirements. Work outside of the project site will require a preconstruction pre-planning meeting specific to the work performed and shall be coordinated no less than one week prior to the performance of such work.

- All required permitting will be obtained before any excavating is to begin.

- If necessary, tabulated data/engineering for shoring and shielding systems will be obtained and available on site at all times when in use.

- All excavations will be inspected by a competent person on a daily basis. Written excavation inspections will be done if the excavation exceeds 5’.

- Dig Safe Notification – dig safe number (If needed) will be obtained and posted in the site office.

- Copies of shoring engineering and tabulated data sheets for all trench boxes or other shoring/shielding systems brought on site will be provided to Consigli and be kept in construction office.

- Designated flagman will be utilized during all work that directly or may indirectly effect the public.

** Please review chapter 19 of Consigli’s Safety and Health Program for additional details**

FALL PROTECTION: All work at 6 feet or greater will require competent forms of fall protection in accordance with CCNY fall protection policy and ANSI Z359.2-2017 Fall Protection Code. Fall protection processes for all roof work and floors with leading edges shall be assessed by the subcontractor’s Competent Person but it is critically important that all elevated work by any subcontractor contracted by Consigli Construction have a written Fall Protection Plan reviewed by the Regional Safety Manager prior to the onset of work. At a minimum the following shall apply;

- Holes greater than 2” will be covered with acceptable material (3/4” plywood or ½” steel) which will be secured and marked cover or hole (cover must be able to withstand four times the intended load). Covers will stay in place until the hole/penetration has been filled.

- Before any work is to begin on the roof, it must be determined what method of fall protection will be implemented. Whenever roofers and any other trade are on the same roof then the flagging must be pulled in to the maximum 15’ distance. Roof work fall protection will require a rail system and flagging. NOTE: At no time will roofers be able to work without positive fall protection.

- Guardrails (Cable, wood or acceptable materials) shall be installed as fall hazards of 6’ or greater are created during all phased work processes. All guardrails systems shall be capable of withstanding downward/outward force of 200 lbs. and shall be maintained in such fashion throughout all phases of construction or until the fall hazard has been eliminated through design or equivalent protection.

- Toe boards are required to be installed any time in which there is a risk for materials to be knocked off of an edge, or material will need to be kept and secured a minimum of 6’ from the roof edge. In addition, any materials that may be blown off of the roof shall be secured/weighted down.

- All Fall Protection Plans shall be drafted by a competent person and shall include all fall protection systems available to ensure the proper form of fall protection is available at the time of work. As per NYS Labor Law 240/241 each subcontractor owner shall ensure that for all work at heights 6’ or greater that all optional forms of fall protection shall be made available for each of his/her workers on site.

- All written fall protection plans shall be developed to include fall rescue procedures and identification of competent rescue supervisor. The fall rescue plan will require periodic review to align with the changes of construction operations.

** Please review chapter 13 of Consigli’s Safety and Health Program for additional details **

ELECTRICAL REQUIREMENTS: All electrical tools, cords and equipment must be in good working order. Ayco project will require that exit lighting and interior stairway and corridor lighting be illuminated 24 hours a day 7 days a week. To that end, all electrical tools and components must be visually checked on a daily basis and include the following;

- Any tools with damaged cords must be taken out service immediately.

- All cords must be equipped with a ground pin, flat three wire cords are not allowed.

- SJO and SJT or other similarly rated cords only shall be used.

- All cords used on the Ayco Project must be 12 gauge or better.

- The electrician will be responsible for all temp power and any general temp lighting that may be needed.

- Temp lighting strings with cages designed to protect bulbs from damage must be wire tied closed to prevent accidental opening.

- Any exposed electrical temp lighting or empty sockets shall be repaired by electrical subcontractor immediately upon notice.

- Subcontractor electrician shall conduct weekly inspection of all temp lighting strings for deficiencies.

- Subcontractors will be responsible for task lighting in the event that lighting above the OSHA standard is required for a particular work task.

- The electrician will coordinate all lock out tag out procedures. All temporary power for the project will be installed on protected and dedicated circuits with 100% GFCI protection.

- GFCI will be tested by the electric contractor to assure proper function with a log book filed with CCNY monthly.

- All live electrical work will be conducted per NFPA 70E.

- All portable generators/welding generator systems shall be equipped with GFCI protection.

- If systems are not equipped with GFCI protection, all workers utilizing system for temporary power shall utilize plug-in type GFCI devices to protect all workers from electrical shock.

- Consigli Construction (CCNY) reserves the right to disable any flexible cord on site when cord is found to be in non-compliance with this section. Disabling means of all non-compliant flexible cords is at the discretion of Consigli Construction up to and including cutting of cap and plugs to ensure flexible cord cannot be utilized to create a greater hazard.

** Please review chapter 26 of Consigli’s Safety and Health Program for additional details**

WORK ON LADDERS: All work on step ladders/straight ladders will be performed correctly per manufacturer’s recommendations and meet at a minimum the following;

- All subcontractors must first assess working conditions and incorporate use of scissor lifts or approved scaffold systems prior to utilizing ladders.

- Any worker who is on a step/straight ladder and could be exposed to a fall greater than the height of their work on the ladder will be required to tie off with manufactured approved personal fall arrest systems.

- Step ladders will not be used as a form of access/egress to or from a walking /working level.

- All straight ladders will be tied off when installed for use.

- Only ladders with a rating Type 1A or 1AA will be allowed on the project.

- Basic ladder safety must be adhered to at all times and it is recommended that each subcontractor have as their first tool box talk – “ladder safety”.

- Extension ladders are to be utilized as access/egress systems only and shall not be utilized to perform work.

SCAFFOLD/ELEVATED WORK PLATFORMS: (CONSIGLI ROGRAM APPENDIX EE – SCAFFOLD CHECKLIST)

Scaffold systems may be utilized on this project but with most exterior work done out of aerial lifts or possibly some swing staging if necessary. If scaffolding is used;

- It will be inspected daily, before each shift by a competent person designated by each individual contractor using it.

- All scaffolds shall require fall protection when platform height is six feet or more above the working surface.

- A “Competent Person” (one who is able to identify hazards associated with the work he/she is supervising and have the authority to stop work whenever he/she determines that an operation is proceeding in an unsafe manner) must inspect the scaffolding before work begins or if any change is made in the scaffolding. The Consigli “Daily Inspection Checklist” must be completed and coincide with the initialing of the color coded (Red, Yellow, and Green) “Scaffold tag”. Completed scaffold checklist shall be submitted to project office prior to work commencing on said scaffold.

- A scaffold checklist will be provided by CCNY to the subcontractors’ designated persons to aid them with their inspection.

- Baker/mobile scaffolding will be required to be equipped with guardrails when the fall exposure is greater than 4 feet. Outriggers will be required when the working level has a height to base width ratio greater than two to one.

- Rolling and Mobile scaffolding must have all wheels locked prior to any employee accessing the work platform. Also scaffolds are not to be moved while workers are on the platform. (No riding on scaffold by workers). Casters must be in the locked position.

- All scaffolding that is over 15’ in height will require that CCNY’s Safety Department review the scaffold prior to it being turned over for use by tradesmen.

- Any Hydro-Mobile systems used on Ayco will require pre-construction safety meeting and subcontractor installing system provided Chapter 15 (Hydro-Mobile Requirements) of CCNY’s Safety and Health Program.

- All scaffold planking shall be scaffold grade. Dry rot or large cracks deem the planks to be unacceptable and shall be removed accordingly. Unacceptable planking can be used for concrete forms, mud sills or toe boards. All scaffold platforms are to be clean and clear of debris. Additionally all scaffold work platforms/planks shall be kept clear of ice and snow at all times and prior to any one walking or working on said planks or platforms.

** Please review chapter 14 of Consigli’s Safety and Health Program for additional details**

AERIAL/SCISSOR LIFTS: (CONSIGLI PROGRAM APPENDIX HH – SCISSOR LIFT INSPECTION FORM, APPENDIX JJ – AERIAL LIFT INSPECTION FORM)

Aerial and Scissor lifts used on the Ayco project will require consistent monitoring of construction operations to ensure workers operate such elevated platforms under the safest site conditions. This will include at a minimum the following;

- Area and ground conditions in the intended work area will be inspected for overhead power lines, sink holes, covers, or any other unsafe conditions.

- Aerial and scissor lift platforms, if utilized, will be inspected daily before each shift by a competent person designated by each individual contractor utilizing them.

- All contractors who will be performing work from an aerial lift will show documented proof of training for each worker using said lifts.

- If necessary, steel plates, or equivalent, will be placed on the ground above known underground structures if lifts will be operating on them.Workers will be tied off at all times when using an aerial lift.

- Required fall arrest systems for the type of work platform lift utilized is supplied and used by each worker operating or using lift. Fall arrest equipment required shall be supplied by the subcontractor employer.

- Elevated platforms shall be used as per the manufactures recommendations. All operators’ manuals shall be kept with each piece of equipment utilized.

- All manufacturer Safety Warnings on the elevated platforms shall be in good condition and legible.

- When determining safe operation of aerial/scissor lifts during wind conditions, the “Beaufort Scale of Wind Force” chart detailed on Page 14 shall be referenced.

** Please review chapter 14 of Consigli’s Safety and Health Program for additional details **

THE BEAUFORT SCALE OF WIND FORCE (BELOW) is accepted internationally and used in communicating weather conditions. It consists of number 0 – 12, each representing a certain strength or velocity Corp of wind at 33 feet (10m) above ground or in the open. This should be used to assess when it is safe to operate your powered access equipment.

| Description of wind |

Specification for use on land |

MPH |

| 0 Calm | Calm, smokes rises vertically | < 1 |

| 1 Light Air | Direction of wind shown by smoke drift but not by wind vanes | 1 – 3 |

| 2 Light Breeze | Wind felt on face; leaves rustle; ordinary vanes moved by wind | 4 – 6 |

| 3 Gentle Breeze | Leaves and small twigs in constant motion; wind extends light flag | 7 – 10 |

| 4 Moderate Breeze | Raises dust and loose paper; small branches are moved | 11 -16 |

| 5 Fresh Breeze | Small trees in leaf begin to sway; crested wavelets form on inland waters STOP MOST POWERED ACCESS PLATFORM & BOOM WORK! | 17-21 |

| 6 Strong Breeze | Large branches in motion; umbrellas used with difficulty | 22 – 27 |

| 7 Near Gale | Whole trees in motion; inconvenience felt when walking against wind | 28 – 33 |

| 8 Gale | Breaks twigs off trees; generally impedes progress | 34 – 40 |

| 9 Strong Gale | Slight structural damage occurs, slate blows off roofs | 41 – 47 |

| 10 Storm | Seldom experienced on land, trees broken or uprooted, “considerable structural damage” | 48 – 55 |

| 11 Violent Storm | Generally not experienced on land. On the water: Exceptionally high (37-52 ft.) waves, foam patches cover sea, visibility more reduced |

56 – 63 |

| 12 Hurricane | On the water: Air filled with foam, waves over 45 ft., sea completely white with driving spray, visibility greatly reduced | > 64 |

Note: Approximate corrections for wind speeds at other heights are:

6 feet subtract 30 percent

10 feet subtract 20 percent

20 feet subtract 10 percent

50 feet add 10 percent

100 feet add 25 percent

SEVERE WEATHER (Requirement added from LeChase Constructions SSSP Pg. 20 Section 5)

In the event weather advisories indicate the possibility of a severe weather alert at or near the Ayco Project, Consigli Construction, LeChase Construction and all subcontractors under GC’s contract shall be responsible for securing all loose material and equipment within their areas of responsibility. All buildings, field storage facilities, chemical toilets, etc. must be anchored when erected. Assembly areas will be designated and reviewed with all project participants.

Cranes shall be secured when wind speed reaches 25 mph. Always refer to the crane manufacturers’ manual for details on each individual crane.

Extreme Environment

- Heat Stress – Drink water regularly, avoid hot food/ drink and drinks with caffeine. Avoid wearing tight fitting or colored clothes. Provide hot weather awareness training to all workers exposed to hot environments.

- Cold Stress – Layer clothing and cover exposed skin, wearing insulated clothing and footwear. Provide cold weather awareness training to all workers exposed to cold environments.

- Wind – Ensure that mobile equipment, hoisting operations, ladders, scaffold and aerial lifts are designed to operate in the anticipated conditions. Halt any operation that may be adversely impacted. Secure tarps, materials (decking, plywood, Styrofoam, debris, etc.) and form panel, for example to prevent overturning, flying or upset. Construction activities such as steel erection, etc. should be planned in accordance with the extended forecasts to ensure adequate winds and weather.

CHEMICAL AND MATERIALS: All Materials and chemicals used on-site will have an SDS provided before being brought onsite.

- All Chemicals transferred from original containers shall be labeled.

- SDS sheets on file with Consigli Construction’s Site Safety Plan

- All SDS sheets shall be readily accessible.

SAFETY DATA SHEETS (SDS)

Consigli will not develop material safety data sheets but instead depends on the manufacturers, distributors and/or suppliers to provide this information in a timely fashion. The Site Superintendent is responsible for obtaining and replacing outdated material safety data sheets for all products used on the site. The SDS file is reviewed periodically by the Safety Coordinator to ensure that every hazardous product has a corresponding data sheet. Copies of the applicable SDSs are maintained by the Site Superintendent in the office trailer and are available to site employees and subcontractors on request. While respecting a company’s right to protect secret formulations (trade secrets) SDS’s which omit health and/or safety information will not be adequate to meet Consigli’s requirements. No new product containing a hazardous chemical(s) may be purchased or used without first reviewing the corresponding SDS to determine the extent of the hazard and how to properly protect Consigli employees from overexposure.

** Please review chapter 20 of Consigli’s Safety and Health Program for additional details **

FIRE PROTECTION: (CONSIGLI PROGRAM APPENDIX OO – HOT WORK PERMIT)

Consigli construction will be adopting NYS Building Fire Code, Chapter 14 “Fire Safety during Construction” and maintaining compliance of the aforementioned fire code throughout construction. It is for this compliance requirement that at a minimum one of the following shall be supplied;

- When Consigli Construction fully Controls site as per contract, Public Fire Alarm/Call box shall be readily available at a designated location outside the project site gate or,

- Instructions shall be posted near the call box that identifies;

- 911/Fire department direct telephone number

- Address of the project site

Consigli’s hot work permit program (Appendix OO) shall be implemented for all hot work to be conducted on the project. This work shall be coordinated and executed through Consigli’s Superintendent. The following additional policies shall be incorporated during all Hot Work on Ayco;

- If required by the nature of the work the Consigli Superintendent shall initiate “Confined Space Permits” or “Hot Permits”.

- Consigli shall perform all hot work in accordance with the Fire Code of New York State and the Hot Work Program approved for the work.

- Consigli Superintendent shall take all reasonable precautions against fire and provide all temporary plans, programs, equipment, labor and material required for compliance.

All hot work will be attended by trained “fire watch” and shall stop one half hour before the regular end of the day work. All combustible or flammable materials will be stored in an appropriately rated lockable cabinet located no closer than 50 feet from the nearest structure.

Fire extinguishers will be provided for every 3000 square feet of building area and maintained during construction. In addition;

- All extinguishers shall be installed on job made stands and conspicuously located throughout the project.

- All extinguishers shall be part of the daily inspection with extinguisher log completed monthly.

- Storage of any oxygen or acetylene cylinders will be done in a secure and upright area, with good ventilation.

- Ayco project will strictly enforce “No Smoking” outside the Designated Smoking location set forth in the site logistics plan.

- Noncombustible materials (metal or fire retardant material) for scaffold, trash chutes, forms, shoring, bracing, temporary stairs, ramps, platforms and boxes shall be used when such items are required during the work.

- Temporary fuels used for temp heat or equipment filling shall have minimum 20lb. ABC multi-purpose extinguisher mounted/located a minimum of 20 feet with identification signage.

- Temporary fuels shall have barricade protection

- Temporary fuels shall have signage indicating “No Open Flames” and “No Smoking”.

- Each temporary heating unit shall have its own designated multi-purpose extinguisher rated no less than 10lb. ABC.

** Please review chapter 17 of Consigli’s Safety and Health Program for additional details**

CRANES: All crane operations (if used on Ayco Project) shall be performed under OSHA’s new subpart CC standards. There is a requirement to assure that certified riggers, signalmen, and crane assemblymen are utilized. All picks are to be done by a licensed operator. As previously mentioned, a detailed pick plan will be required to assure that no picks are critical in nature. Critical picks are defined as those involving 2 cranes lifting simultaneously, a pick that is over 75% of capacity, a pick that involves the lifting of a man basket, or any other lift that is deemed to involve special conditions. Location and set up will be reviewed with crane operator prior to set up and pick. All lifting operations will require that the operator and any involved contractors follow the steps listed below as well as in CCNY Crane Safety policy.

- All Hoisting equipment will have an up to date 3rd party inspection certificate with the equipment which will be copied and filed in the office trailer.

- All lattice boom cranes will have an independent 3rd

party inspection completed each time one is set up on the project, after assembly and prior to operation. - All equipment operators will be required to have in

their possession all appropriate licensing and training as required by OSHA and the State of New York. - All underground vaults and existing utilities will be

marked before as well as before any crane is set up. - Documented rigging equipment inspections.

- Documented daily crane inspections filed with CCNY

weekly. - Most recent 3rd party annual inspection of the crane is to be supplied to Consigli Superintendent.

** Please review chapter 24 of Consigli’s Safety and Health Program for additional details **

STRUCTURAL STEEL WORK (Related Consigli Program Appendix LL – Approval to Begin Steel Erecting, Appendix MM – Custody of Fall Protection)

No steel erecting work is anticipated on the Ayco project but if applicable all steel erectors must submit to the Consigli Superintendent a site-specific steel erection plan written by a qualified person two weeks prior to commencing work. The plan shall contain minimally:

Site Layout

- Sequence of erection

- Deliveries

- Staging & Storage

- Path of overhead loads

- Lift Plan/Crane Set-up

- Fall protection procedures (fall protection required at 6 feet for all operations)

- Post fall protection plan

- Training documentation

- Qualified and Competent person(s). Including Rigger/Signal person

- Critical Lifts

It shall be assured that the concrete in Footings, Piers, Walls, and/or mortar in Masonry Piers and walls are in accordance with ASTM standard test method and has reached 75% (Percent) of its intended minimum compression design strength and signed off by a qualified person. The Engineers test results shall be documented and sent to the steel erector prior to steel erection commencing utilizing the “Approval to Begin Steel Erection Form” (APPENDIX LL).

Erecting requirements

- Each employee engaged in a steel erection activity that is on a walking/working surface 6 feet or greater above a lower level shall be protected from falling by use of guardrail, safety net or personnel fall protection system. When personal fall protection systems cannot be attached overhead, they must be of the appropriate type to account for 12’ free fall requirements as detailed in ANSI Z359.2-2017.

- Steel erector shall provide a written fall protection plan. The written plan shall be developed to include fall rescue procedures and identification of competent rescue supervisor. The fall rescue plan will require periodic review to align with the changes of construction operations.

- Welded alloy steel chain slings shall have permanently affixed durable identification stating size, grade, rated capacity, and sling manufacturer.

- Perimeter columns should have holes at 45 inches above the structural slab to install 3/8 inch air craft grade cable or if using other devices then it must meet the fall protection requirements (200 pounds in an outward and downward direction) or the anchoring point requirements (5000 pounds per person tying off to it). All wire rope shall be secured with at least three (3) Crosby Clips. (APPENDIX MM)

- Steel subcontractor shall on all perimeter cable guard railings install turnbuckles on each straight run. Subcontractor is prohibited from installing cable guard railing round column corners.

- All angle steel upright corner stanchions for cable guard railing shall have support steel angle welded at minimum 75% the height of the vertical stanchion to ensure structural integrity during cable guardrail adjustment and maintenance.

** Please review chapter 16 of Consigli’s Safety and Health Program for additional details **

Back– End of Site Safety Plan

Environmental Emergency Contact and Management Response

Consigli’s identified Environmental Emergency Response Subcontractor

Quality Environmental Solutions and Technologies, Inc. (845)298-6031

1376 Route 9 Wappingers Falls, NY 12590

Confined Space Entry

A confined space is defined as an area which

- Is not meant for continuous use.

- Has adequate size and configuration for employee entry

- Has limited means of access and egress

- Is not designed for extended employee occupation

Before any work is commenced in what might be considered a confined space, Consigli’ Superintendent shall be notified. Consigli’s Superintendent and the Foreman of the company who will have employees working in a confined space will determine the requirements for working in this space.

Before entering a confined space, an atmosphere test of the confined space must be conducted and the results noted. If any contaminant is found, mechanically blown fresh air is required at all times. The employee entering the space must wear a safety harness with a lanyard. A second person is required outside the space to monitor the worker. If the person in the space is out of view of the monitor then a radio may be required. In some cases a tripod with a rescue line attached to the worker’s body harness may be required.

Before entry is made into any manhole, duct, vessel or any other confined space, as defined by the OSHA 1926 standard, Consigli Construction’s confined space entry permit shall be completed by the trade contractor’s supervisor/competent person and a copy shall be submitted to Consigli’s Superintendent.

SILICA EXPOSURE REQUIREMENTS DURING CONSTRUCTION: Where applicable, Consigli Superintendents shall ensure that all related construction activities with potential for Silica exposure will be consistent with OSHA’s Construction Standard Table 1 (APPENDIX DDD).

Superintendents are to ensure that each employee and subcontractor engaged in a task identified on OSHA’s Construction Standard Table 1 have fully and properly implemented the engineering controls, work practices, and respiratory protection specified for the task on Table 1.

Competent Person Requirements

All subcontractor employers shall identify a competent person to inspect and manage all activities with potential airborne silica exposure. Subcontractors working on projects within the scope of this Program shall appoint a competent person capable of managing and executing the duties described herein. The competent person must have training in the inspection of work areas and equipment and in the determination of safe working conditions. This person shall have a working knowledge of the 1926.1153 standards, shall be capable of identifying airborne silica hazards, shall determine the need for initial and additional exposure monitoring, shall recommend and implement engineering and work practice controls as outlined in Table 1, shall establish levels of PPE, and shall have the authority to take action to eliminate hazards and correct incidences of noncompliance.

DESIGNATED FIRST AID PLAN: All injuries must be reported to Consigli immediately. CCNY will then report all injuries to the CCNY Regional Safety Manager. A fully stocked first aid kit and blood borne pathogens kit shall be maintained on the project site. Only properly trained personnel will administer first aid.

IMPORTANT: All eyewash stations shall be maintained in a clean condition throughout the projects scheduled completion date.

** Please review chapter 1 and 27 of Consigli’s Safety and Health Program for additional details **

EVACUATION PLAN (RACE, AND ROUTES OF EGRESS): Please refer to the Logistics Evacuation Plans attached. All contractors’ employees shall attend CCNY Construction Project Orientation. Consigli Construction’s Job Supervisor will conduct a safety orientation talk to each employee and subcontractor to site specific fire safety protocols.

** Please review chapter 8 of Consigli’s Safety and Health Program for additional details **

LEAN REQUIREMENTS/MATERIALS MANAGEMENT/HOUSE KEEPING: Getting materials into and out of the Ayco project will be a challenge that needs to be adequately planned. All deliveries are to be scheduled with the CCNY Superintendent and LeChase Construction where said deliveries effect their daily operations. A comprehensive Activity Hazard Analysis shall be done on all materials that will be hoisted and placed into the building. Only materials which will be used/installed within three days’ time will be delivered to the site. Attention must be paid to structural analysis in regards to loading existing floors with material and equipment. Listed below are additional Lean requirements;

- Consigli Superintendent has the right to refuse any deliveries not properly scheduled or due to logistical constraints as necessary.

- All subcontractors’ delivered materials shall be placed on wheeled carts, wheeled racks or in wheeled bins so as to necessitate easy relocation in the event materials need to be moved. Carts, racks, or dollies shall not exceed manufacturers intended weight loads. Materials/tools can be delivered and stored on pallets only if pallet jacks are delivered simultaneously with said delivery to provide for ready mobility. Additionally, pallet jacks need to remain in immediate area. Each subcontractor will need to supply their own pallet jacks for their own materials and keep their pallet jack within reasonable distance at all times.

- All work stations shall be provided with wheeled trash bins for immediate placement of all debris produced as a part of the subcontractors operations. All trash will be immediately placed in wheeled containers provided by Consigli.

- All subcontractors shall use rubber wheeled carts when moving material or removing trash from a building. Any damage caused by the Subcontractor shall be repaired at the cost of the Subcontractor. Back charges will be appropriately assessed for the cost of the repairs. No trash or materials shall be left on the floor.

- Subcontractors shall, where feasible, elevate all electrical extension cords, hoses, or cables – removing them from all walking/working surfaces. Electrical Cords, when elevated shall be supported or suspended in a manner that does not subject them to damage.

- Storage of delivered materials in cardboard containers shall be discouraged. When materials must stay in cardboard containers, said containers shall be removed from the projects immediately after product is unpacked.

- Subcontractor will participate in schedule development meetings as required by Consigli.

- All staging areas for materials shall have a barrier set up and be staged in a manner that does not impact ongoing construction operations.

MATERIALS MANAGEMENT & STAGING: Getting materials into and out of the project will be a challenge that needs to be adequately planned. All deliveries are to be scheduled with the CCNY Superintendent. Consigli Superintendent shall sequence and manage the scheduled work to account for the space for materials storage and work related activities provided in the available staging area outlined in the site logistics plan. In addition;

- All materials shall be staged in a neat and orderly manner.

- All materials that have limited exposure to weather as outlined by the manufacturer shall be protected against the weather by weatherproof temporary covers or storage facility or trailer.

- Security for stored materials shall be the responsibility of the Contractor.

- Storage of materials is not permitted on the roof of the Ayco building unless approved by Consigli’s site superintendent and secured methods implemented to prevent displacement during work and severe weather conditions.

MOLD MANAGEMENT: Mold issues are not anticipated to be prevalent on this project, however if mold is discovered, Consigli’s mold remediation policy will be implemented and followed.

WATER EXTRACTION AND MOLD REMEDIATION

A clear delineation needs to be made as to whether the water extraction/mold remediation is to be managed by Consigli personnel or by qualified water extraction subcontractor. If the water source is clean water and the area is small enough to be managed, properly trained Consigli project personnel can be utilized. If the area is too large then a qualified water extraction subcontractor will be utilized.

In the event that the water is of the black or gray color, then a professional water extraction subcontractor needs to be utilized. The PM and Safety Director need to assure that a clear objective for the utilization of specialists with in each of the areas above needs to be established to understand and account for the deliverable services they render. This shall be a part of their proposal.

Mold Remediation identified by Consigli Personnel

The Consigli Mold Management Program requires that Consigli personnel involve a Certified Industrial Hygienist (CIH) for all identified mold regardless of affected area size.

First response actions include:

- Restriction of personnel from the mold area.

- Minimizing or stopping the air flow in the mold area.

- Notification of the Project Manager and Safety Director.

- Notifying of a designated CIH for approved and professionally directed remedial actions.

Water Extraction

Because the window of opportunity for the prevention of mold growth is the first 48 hours, water extraction activities must commence immediately to begin dry-out process or to remove building materials to prevent fungal growth. During the course of the dry-out, the water extraction activities shall be documented as all dry- out activities are performed. Upon completion of the dry-out a brief written report shall completed by the Project Superintendent assessing their perceived effectiveness in preventing mold growth from occurring. The Superintendent shall forward all reports to the PM and Regional Safety Manager.

** Please review chapter 22 of Consigli’s Safety and Health Program for additional details **

NOISE: Noise exposure will also be a concern so all deliveries must be coordinated with CCNY Superintendent to limit their impact on the surrounding areas. Normal working hours will be between 7:00 am and 4:00 pm Mon-Fri. Any contractor who may need to work outside the contracted work hours specified in this section must first seek approval from the CCNY Superintendent. Noise levels will be monitored when high levels of noise could be expected to assure that noise levels do not exceed acceptable OSHA levels. Consigli permissible noise policy and procedures will be followed. All subcontractors will be required to have and maintain a written hearing conservation program at the time of work that outlines control measures designed to mitigate and control worker noise exposure. At a minimum the following shall be part of the subcontractor’s safety and health noise management program;

- Consigli superintendent shall coordinate with LeChase Construction on all excessive noise levels in order to minimize the impact to any surrounding facilities and workers under LeChase Contract.

- Subcontractor supervisor shall protect workers from exposure to noise when such exposure has the potential to exceed OSHA’s Permissible Exposure Limits outlined in Table D-2 of 1926.52(d)(1).

- Subcontractor supervisor shall upon competent evaluation of a workers exposure to noise ensure that the worker is monitored and protected and that all engineering and administrative controls necessary to protect worker from hazardous noise levels are implemented.

- Subcontractor employer shall be responsible for supplying proper hearing protection where and when required.

- Subcontractors shall ensure all tools and equipment being operated on Ayco site are equipped with the appropriate manufacturer’s recommended noise reduction device(s), including a muffler and jacket, free from air or exhaust leaks.

- Subcontractor employer shall be responsible for ensuring all workers are trained in the proper use of personal protective equipment designed to protect employees from noise levels that exceed those outlined in OSHA’s Table D-2 described in this section.

** Please review chapter 29 of Consigli’s Safety and Health Program for additional details **

HEAVY EQUIPMENT USE: (CONSIGLI PROGRAM APPENDIX UU – POWERED INDUSTRIAL TRUCK CHECKLIST)

All heavy equipment including Powered Industrial Vehicles (Rough Terrain Forklifts)

- All operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the State of New York.

- All safety devices and warning alarms must be in good working order and all leaks are to be repaired immediately.

- All equipment will be used in accordance with the manufacturer’s recommendations for safe usage and have its operators manual as well as an extinguisher with it at all times.

- Subcontractors who will have equipment on site will be responsible for having a spill kit available at all times.

- All heavy equipment shall be maintained in a safe manner and shall be regularly inspected for operational deficiencies and damage caused during construction use.

** Please review chapter 24 of Consigli’s Safety and Health Program for additional details **

SANITARY REQUIREMENTS

The amount of sanitary facilities required shall be based on the total number of workers employed on the Project and shall be in accordance with OSHA’s provisions outlined in Table D-1 of 1926.51(c)(1). At a minimum the following shall apply in order to maintain the highest level of sanitary conditions during and up to completion of construction;

- Maintain all units in a clean and sanitary condition.

- At the minimum, clean on a weekly basis, and more often as required by the applicable OSHA sanitary standards for amount of workers on the project site.

- Provide all toilet supplies as required, including toilet paper, soap, paper towels, and waste receptors.

EXPOSURE TO THE VISITORS AND PUBLIC: Non fraternization with visitors or public will be stressed with all subcontractor personnel during orientations the protection of the public is paramount when heavy equipment is scheduled to exit or enter the project site to and from public Highways.

ADJACENT PROPERTY: All efforts will be made to ensure that property adjacent to the work area remains un-impacted.

PLANNING: (CONSIGLI PROGRAM APPENDIX E – COMPETENT PERSON ID FORM) The project team, as well as CCNY safety department, will meet with each subcontractor before they start to review their Site Specific Safety and Health Program and all project specific Job Hazard Analyses. The project team shall be an integrated mix of Construction personnel. After reviewing the programs and meeting with the individual subcontractor, if the team is satisfied with the risk control direction, they will be permitted to begin work. Elements of the pre-planning safety meetings shall include at a minimum;

- Scope of work performed by the subcontractor

- Number of employees that the subcontractor will need to fulfill the contracted work

- Scheduled start date

- Review of potential hazardous conditions associated with the contracted work

- Safety measures subcontractor will implement to protect workers and workers of other trades

- Required licensing and training requirements

- Copy of subcontractors written safety and health program

- Review by Consigli’s safety department of required written safety programs specific to high hazard work processes

- Identification of subcontractors Competent Person (Appendix E)

** Please review chapter 2 of Consigli’s Safety and Health Program for additional details **

LOSS EXPOSURES AND CONTROLS/ INCIDENT REPORTING: (CONSIGLI PROGRAM APPENDIX R – SUPERINTENDENTS INCIDENT REPORT, APPENDIX GG – NEAR-MISS REPORT)

All individuals working on this project will go through a comprehensive Safety Orientation which will cover all company safety rules regulations and procedures.

- All personnel working on site shall have documentation of an OSHA 10 Hour Construction Safety Outreach Training minimally.

- Fraternization between construction employees and the public, or visitors will not be permitted.

- Loud and profane language or clothing with offensive language will not be allowed on the jobsite. Extra efforts must be made to keep noise to a minimum.

Incident Reporting

Consigli’s Project Superintendent must be verbally notified by the subcontractor’s supervisor immediately that an accident has taken place and that one or more of his employees has been injured. Any injury, even minor in nature, requiring a visit to an outpatient medical clinic for treatment, must be reported, by the Consigli Superintendent, on the Consigli “Incident Investigation Report” (APPENDIX R).

The Consigli Superintendent must verbally notify the Corporate Safety Manager of any Injury Incident as soon as possible and submit the aforementioned written investigation reports within 24 hours. Maintain a copy of all accident reports on file at the jobsite

Damage to Property: Any property damage accident, whether project property or non-project property, must also be reported on the Consigli Incident Investigation Report Form” (APPENDIX R) as well.

The Consigli Superintendent must verbally notify the Corporate Safety Manager of any damage to property as soon as possible and submit the aforementioned written investigation reports within 24 hours. Maintain a copy of all accident reports on file at the jobsite

Near Misses

A near miss is a potential hazard or incident that has not resulted in any personal injury or property damage. Unsafe working conditions, unsafe employee work habits, improper use of equipment or use of malfunctioning equipment have the potential to cause work related injuries. It is everyone’s responsibility to report and/or correct these potential accidents / incidents immediately.

General Program:

- Any employee can fill out a near miss report (APPENDIX GG) and forward it to the Superintendent to submit to the Safety Department. Please include photographic documentation.

- Each jobsite is encouraged to investigate and report all near misses.

- Near Miss IHTUs will be reviewed at each Quarterly Safety Meeting.

OSHA Reporting Requirements

All OSHA related reporting requirements shall be coordinated through the Regional Safety Manager. OSHA has outlined basic mandated reporting requirements under section 1904 addressing all of the following Accidents;

- Within 8 hours for any job related fatality

- Within 24 hours following in-patient hospitalization of 1 or more employees within 24 hours of employee amputation or loss of an eye

NOTE: Incidents involving worker injury or property damage must be reported to Consigli’s Safety Department immediately by the project team.

** Please review chapter 9 of Consigli’s Safety and Health Program for additional details **

Back– End of Environmental Emergency Contact and Management Response