UNH-Buckman West Labs (3rd Floor)

300 Boston Post Rd West Haven, CT 06516

Project #2004

Emergency Response Plan

EMERGENCIES SHOULD BE REPORTED BY CALLING 9-1-1

In the event of an emergency the following policy will be adhered to for the safe evacuation of the Project. An immediate call will be made to Emergency 911

A Consigli representative will be dispatched to the front of the building to meet the responding Emergency Personnel and advise the individual in charge of the location of any chemicals or hazardous substances that may be present on any of the floors. SDS’s will be readily available if needed by the Fire Dept.

In the event of a serious injury requiring the assistance of EMS the injured worker will be kept as comfortable as possible. Emergency first aid if necessary will be administered. Under no circumstances will the injured person be moved unless the worker’s life is in danger because of fire or calamity. A worker will be assigned to meet the medical personnel to direct them to the location of incident.

In the event an evacuation is required, all personnel at this job site will assemble at the muster point. The foreman for each company will meet at that location and take a count of their staff. If for some reason a worker is unaccounted for, the fire department will be notified of the last location where the worker was observed.

Back– End of Emergency Response Plan

Emergency Contact Names and Numbers

First Call: CC Project Superint: Rick LaPointe: (860)471-7428

2nd all: CC Asst.Project Manager: Mark Harmon: (860)324-1762

3rd Call: CC Project Manager: Lee Blackwell: (860)462-7460

4th Call: CC Safety Director: Dan Della-Giustina (508)686-6008

Owners Emergency Contact

Carmine Amento: (203)645-5590

Back– End of Emergency Contact Names and Numbers

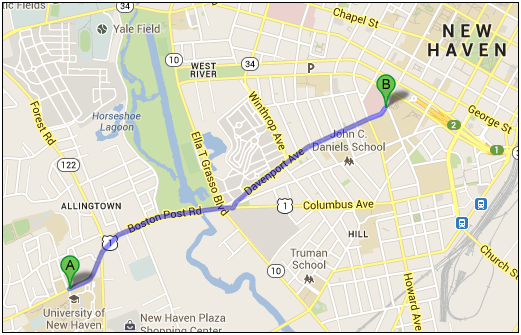

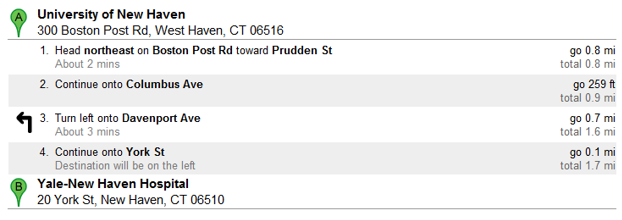

Medical Facilities

Yale-New Haven Hospital

20 York St. New Haven, CT 06510

(203)688-4242

Back– End of Medical Facilities

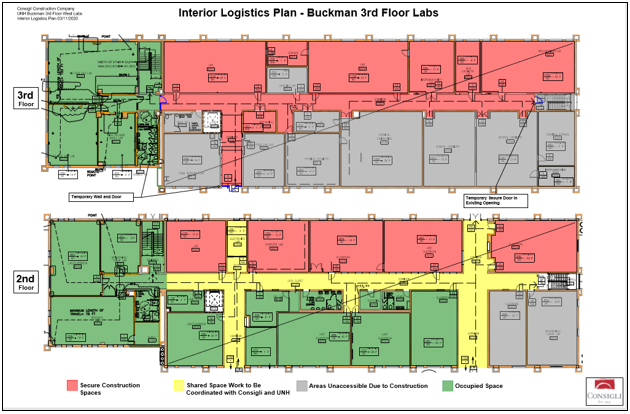

Site Safety Plan

Scope of Proposed Operations: The Buckman Hall West Labs is a part of Consigli ongoing renovation work in UNH Buckman Hall. Starting in Spring 2020 and ending Summer 2020, the West Labs will consist of new chemistry lab space on the 3rd floor on the West end of Buckman Hall. Interior demolition will make way for new MEP layout and floor polishing. Labs spaces will be fit out with (26) fume hoods that will tie into the exhaust system. There will be new electrical service for the area. The finishes will include all new lighting, floor, ceiling, and lab furniture/casework fit out. 1 New exhaust fan will be added to the new utility building for increased capacity.

Identify the specific route in and out of the construction site (Traffic Management): For this project all deliveries and waste removal shall enter using designated access points and be coordinated with the Consigli and University of New Haven. Also, only permitted truck routes will be used. All contractors will be responsible for adhering to the logistics plan, which will be made available to all sub-contractors.

Designated work hours (any work outside these hours must have prior CCC approval): Work shall take place during business hours, Monday – Friday 7:00am to 3:30pm. There will also be some off-hours work at times. Any work which may need to take place outside of normal hours will need to be approved by the CCC Superintendent, and may need to be coordinated with University of New Haven.

Demolition: Prior to the start of demo operations, all subcontractors are required to review the hazardous material report. Hard copies of the hazardous materials report can be found in the Consigli field office. The demo contractor will confirm that all utilities leading into the area have been made safe. The electrician will disconnect and lock out all electrical, the plumber will do the same with any plumbing lines, and the HVAC subcontractor will do the same on the HVAC piping and duct work. Lock out tag out will be reviewed during the pre-construction safety meetings to assure disconnect and responsibility for protection of existing utilities is safe for any construction activities to commence.

In spaces where some electrical or mechanical must remain live, a color coding system will be utilized for easy identification of live utilities that must stay active and utilities that must be removed. Any and all utilities spray painted Red are not to be touched and are need to be protected during all operations. Utilities spray painted Green are to be removed as part of the selective demolition process only after lock-out/tag-out has been confirmed and utilities tested. If any utilities are unmarked, they shall be considered live. The demo contractor will be responsible for completing CCC demo checklist prior to the start of any work in their target areas.

Fall Protection: Limited exposures. Roof work will require fall protection. All work over 6 feet above a lower level will require some form of fall protection in accordance with CCC fall protection policy. All scaffold erectors will maintain the ability to have fall protection by donning a harness and lanyard at all times during erection.

Holes greater than 2” will be covered with acceptable material (3/4” plywood or ½” steel) which will be secured and marked cover or hole (cover must be able to withstand four times the intended load). Covers will stay in place until the hole/penetration has been filled.

Before any work is to begin on the roof, it must be determined what method of fall protection will be implemented (fall protection plan, 100% tie off, guard rails, flagging etc.) Workers on a roof with a slope less than 4 to 1 may put flagging (six feet for roofers-15 feet for everyone else) lines up. Whenever roofers and any other trade are on the same roof then the flagging must be pulled in to the maximum distance.

Toe boards are required to be installed any time in which there is a risk for materials to be knocked off of an edge, or material will need to be kept a minimum of 6’ from the roof edge. In addition, any materials that may be blown off of the roof shall be secured/weighted down.

**Review Chapter 13 for more detail**

Work on Ladders: All work on step ladders/straight ladders will be done correctly per manufacturer’s recommendations. Any worker who is on a step/straight ladder and could be exposed to a fall greater than the height of their work on the ladder will be required to tie off. Step ladders will not be used as a form of access to a walking /working level. All straight ladders will be tied of when installed for use. Only ladders with a rating Type 1A or 1AA will be allowed on Consigli projects. Basic ladder safety must be adhered to at all times.

Scaffold and elevated work platforms: All scaffolds will be inspected daily, before each shift by a competent person designated by each individual contractor that will be using it. The inspections will be documented on Inspection tags located at the access point to each scaffold. A scaffold checklist will be provided by CCC to the subcontractors’ designated persons to aid them with their inspection. Overhead protection will be provided for all access points at any buildings which are located under any form of scaffolding.

The base of the scaffold will require protection from unauthorized individuals. This shall be either a site fence or the base of the scaffold shall be wrapped with plywood extending 8’ in height. All scaffolding that is procured by CCC and is over 15’ in height will require that the CCC Safety Department review the scaffold prior to it being turned over for use by tradesmen.

** Please review chapter 14 for additional details.**

Aerial/Scissor Lifts: Limited to no use expected. Area and ground conditions in the intended work area will be inspected for overhead power lines, sink holes, covers, or any other unsafe condition which causes the potential for an incident. Aerial and scissor lift platforms will be inspected daily before each shift by a competent person designated by each individual contractor who will be using it. All contractors who will be performing work from an aerial lift will show documented proof of training for all workers who will be using the lift. Steel plates or equipment mats will be placed on the ground above any utility/ steam tunnel if there will be aerial lifts operating on them.Workers will be tied off at all times when using an aerial lift.

Chemical and Materials: All Materials and chemicals used on-site will have a Safety Data Sheet (SDS) provided before being brought onsite.

- SDS sheets will be kept on file with Consigli Construction’s Site Safety Plan

- All SDS sheets shall be readily accessible.

** Please review chapter 20 for additional details. **

Fire Protection: The hot work permit program will be implemented for all hot work to be conducted on the project. This will be coordinated through the Consigli as well as the University of New Haven. All hot work will stop one half hour before the regular end of the day work. All combustible or flammable materials will be stored in an appropriately rated lockable cabinet located no closer than 50 feet from the nearest structure. Fire extinguishers will be provided for every 3000 square feet. They will be installed on job made stands and conspicuously located throughout the project. They will be part of the daily inspection with extinguisher log completed monthly. Storage of any oxygen or acetylene cylinders will be done in a secure and upright area, with good ventilation. This will be a strict no smoking project.

**Review Chapter 17 for more detail.**

Electrical: All electrical tools, cords and equipment must be in good working order. To that end, all electrical tools and components must be visually checked on a daily basis. Any tools with damaged cords or damaged cords must be taken out service immediately. All cords must be equipped with a ground pin, flat three wire cords are not allowed. SJO and SJT or other similarly rated cords only shall be used. Cords must be 12 gauge or better. The electrician will be responsible for all temp power and any general temp lighting that may be needed. Subcontractors will be responsible for task lighting in the event that lighting above the OSHA standard is required for a particular work task. The electrician will coordinate all lock out tag out procedures. All temporary power for the project will be installed on protected and dedicated circuits with 100% GFCI protection. GFCI will be tested by the electric contractor to assure proper function with a log book filed with CCC monthly. No live electrical work will be conducted per NFPA 70E.

**Review Chapter 26 for more detail**

Utility Exposures: Before any work is started that may impact known utilities, all due care will be taken to identify the locations of underground utilities. Subcontractors must review field conditions, as-built drawings, Call Before You Dig, etc. to ensure that there is no impact to the utilities.

Crane: At least 2 crane mobilizations are expected:

1) Load duct on roof,

2) New exhaust unit. There may be more for material deliveries. All cranes will require independent annual 3rd party inspections and will be utilized for operation only after detailed lift plans are submitted. It is anticipated that these cranes will be hydraulic. In the event that a lattice boom crane is utilized, then the crane must get an on-site 3rd party inspection once the crane is assembled, prior to operation.

There is a requirement to assure that certified riggers, signalmen, and crane assemblymen are utilized. A site specific erection plan will be required for the structural steel erection with review of certifications prior to any of these operations taking place. All picks are to be done by a licensed operator. As previously mentioned, a detailed pick plan will be required to assure that no picks are critical in nature. Critical picks are defined as those involving 2 cranes lifting simultaneously, a pick that is over 75% of capacity, a pick that involves the lifting of a man basket, or any other lift that is deemed to involve special conditions. Location and set up will be reviewed with crane operator prior to set up and pick. All lifting operations will require that the operator and any involved contractors follow the steps listed below as well as in CCC Crane Safety policy.

1. All Hoisting equipment will have an up to date 3rd party inspection certificate with the equipment which will be copied and filed in the office trailer.

2. All lattice boom cranes will have an independent 3rd party inspection completed each time one is set up on the project, after assembly and prior to operation.

3. All equipment operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the State of CT.

4. All underground vaults and existing utilities will be marked before as well as before any crane is set up.

5. Documented rigging equipment inspections.

6. Documented daily crane inspections filed with CCC weekly.

** Please review chapter 24 for additional details. **

Designated First Aid Plan: All injuries must be reported to Consigli. CCC will then report all injuries to the CCC Safety Director. A fully stocked first aid kit and blood borne pathogens kit shall be maintained on the project site. Only properly trained personnel will administer first aid.

** Please review chapter 1 and 27 for additional details.**

Evacuation Plan (RACE, and Routes of Egress): Please refer to the Evacuation Plan that is posted onsite. All contractors’ employees shall attend CCC Construction Project Orientation. Consigli Construction’s Job Supervisor will conduct a safety orientation talk to each employee and subcontractor to site specific fire safety protocols.

Emergency Management Response: In the event of an Emergency the construction workers shall leave the building immediately and proceed to the muster point indicated in the evacuation plan. In the Event of a DISASTER, the Superintendent or Safety director shall instruct the construction workers to leave the site or remain in place and await further instruction. The following steps should be taken in the event of an emergency

When reporting an emergency, please provide the following:

• Your location, phone number, and name;

• The location of the incident (building name, floor and unit number);

• Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

• The name and amount of the material spilled (if applicable);

• The safest route to the spill (if applicable).

** Please review chapter 8 for additional details.**

Restricted Areas: Contractors are prohibited from entering adjacent buildings/areas unless work has been previously authorized and scheduled. All workers must limit their impact on surrounding areas to the largest extent feasible.

Lean requirements/Materials Management/Housekeeping: Getting materials into and out of the project will be a challenge that needs to be adequately planned. All deliveries are to be scheduled with the CCC Superintendent. A comprehensive Activity Hazard Analysis shall be done on all materials that will be hoisted and placed into the building. Only materials which will be used/installed within three days’ time will be delivered to the site. Attention must be paid to structural analysis in regard to loading existing floors with material and equipment. Listed below are additional Lean requirements

- No materials shall be delivered to the site earlier than 3 days before said materials are to be installed/put into place. If materials have to be delivered before that 3 day time period, subcontractor shall get prior approval from Consigli Superintendent. Because of this, notification / scheduling is required for all deliveries to the site. Subcontractors must notify Contractor at least 24 hours in advance. Contractor has the right to refuse any deliveries not properly scheduled or due to logistical constraints as necessary.

- All subcontractors’ delivered materials shall be placed on wheeled carts, wheeled racks or in wheeled bins so as to necessitate easy relocation in the event materials need to be moved. Carts, racks, or dollies shall not exceed manufacturers intended weight loads. Materials/tools can be delivered and stored on pallets only if pallet jacks are delivered simultaneously with said delivery to provide for ready mobility. Additionally, pallet jacks need to remain in immediate area. Each subcontractor will need to supply their own pallet jacks for their own materials and keep their pallet jack within reasonable distance at all times.

- All work stations shall be provided with wheeled trash bins for immediate placement of all debris produced as a part of the subcontractors operations. All trash will be immediately placed in wheeled containers provided by Consigli.

- All subcontractors shall use rubber wheeled carts when moving material or removing trash from a building. Any damage caused by the Subcontractor shall be repaired at the cost of the Subcontractor. Back charges will be appropriately assessed for the cost of the repairs. No trash or materials shall be left on the floor.

- Subcontractors shall, where feasible, elevate all electrical extension cords, hoses, or cables – removing them from all walking/working surfaces. Electrical Cords, when elevated shall be supported or suspended in a manner that does not subject them to damage.

- Storage of delivered materials in cardboard containers shall be discouraged. When materials must stay in cardboard containers, said containers shall be removed from the projects immediately after product is unpacked.

- Subcontractor will participate in schedule development meetings as required by Consigli.

Back– End of Site Safety Plan

Environmental Emergency Contact and Management Response

IAQ (indoor air quality): This project will occur in an occupied building. A baseline survey of the air quality in the Buckman facility shall be completed prior to the beginning of work. Dust control, housekeeping, and frequent monitoring will ensure no impact on the air quality for the existing building occupants.

** Please review chapter 29 for additional details **

Asbestos: A Hazardous Materials report has been completed by the owners hygienist, ChemScope, on 11/27/2019. All identified asbestos will be fully abated by a licensed and regulated asbestos abatement contractor under a formal plan to be written, submitted, and approved by the DEEP.

IT IS THE RESPONSIBILITY OF ALL SUBCONTRACTOR FOREMEN TO REVIEW THE HAZARDOUS MATERIAL REPORT WITH THEIR WORKERS. A copy of the hazardous Material report will be on site at all times and available to anyone requesting it. This does not mean that asbestos could not still be found in other areas. Caution must be used when working and if any workers identify any potentially hazardous substances, then they should stop and notify their supervisor immediately, who in turn, will notify the CCC Superintendent.

All disposals will be done in compliance with all local, state, and federal regulations. All work will be done in full containment with negative air, decontamination with proper handling, and disposal.

Lead: Unless sampling has been conducted, all painted surfaces will be treated as lead containing. Consult the hazardous materials report for each project location. Consigli Construction does possess historical data to show that drilling, sawing, light demo, installation of hangers, hanging sheetrock, fastening, and carpentry do not put the employee above the action level. Despite this, additional monitoring may be done. Subcontractors with similar historical data may use this in lieu of an exposure assessment. If subcontractors are unable to provide this information, an exposure assessment will be required.

An exposure assessment will be done for any task on painted surfaces prior to the work taking place. This does not mean that lead could not still be found in/on other surface/areas, caution must be used when working and if any workers identify any potentially hazardous substances then they should stop and notify their supervisor immediately. If at any time workers will need to work on the areas mentioned above they will need to obtain Lead Awareness training.

** Please review chapter 29 for additional details **

Silica: Any activity which can produce silica dust will use engineering controls to keep dust to a minimum. A written exposure plan must be developed for all silica producing tasks that clearly defines the following:

1) A description of the tasks in the workplace that involve exposure to respirable crystalline silica;

2) A description of the engineering controls, work practices, and respiratory protection used to limit employee exposure to respirable crystalline silica for each task;

3) A description of the housekeeping measures used to limit employee exposure to respirable crystalline silica

4) A description of the procedures used to restrict access to work areas, when necessary, to minimize the number of employees exposed to respirable crystalline silica and their level of exposure, including exposures generated by other employers.

There will be no dry cutting of any masonry material allowed; if water cannot be used then a dustless vacuum system consisting of HEPA dustless vacuum system will be used. Prior to the project going full scale an exposure assessment of a worker grinding and cutting masonry while using the HEPA system an exposure assessment will be done so as to establish the silica exposure level. No respirators will be issued without the express consent of the Consigli Safety department. Nuisance mask like an N95 if used will be on a voluntary basis and at no time will these types of mask be issued to the workers.

Mold: Mold issues are not anticipated to be prevalent on this project, however if mold is discovered, Consigli’s mold remediation policy will be implemented and followed.

** Please review chapter 22 for additional details **

Noise: Noise exposure will also be a concern so all deliveries must be coordinated with CCC Superintendent to limit their impact on the surrounding areas. Normal working hours will be between 7:00 am and 3:30pm Mon-Fri. Any contractor who may need to work late must first seek approval from the CCC Superintendent. Noise levels will be monitored when high levels of noise could be expected to assure that noise levels do not exceed acceptable OSHA levels. Consigli permissible noise policy and procedures will be followed.

** Please review chapter 29 for additional details **

Equipment requirements: None anticipated for the West Labs Project. All operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the State of CT. All safety devices and warning alarms must be in good working order and all leaks are to be repaired immediately. All equipment will be used in accordance with the manufacturer’s recommendations for safe usage and have its operators manual as well as an extinguisher with it at all times. Subcontractors who will have equipment on site will be responsible for having a spill kit available at all times.

** Please review chapter 24 for additional details **

Exposure to the Visitors, Staff and Residents: During all phases of construction the parking lot and pedestrian walkways around the project will be open and occupied. Some areas of project will be opened for construction at different times; this plan must be followed by all workers. Any pedestrian walkway which finds itself under any type of scaffold or overhead hazard will be provided with overhead protection. At no time is any worker allowed to enter any of the adjacent buildings, unless they have a scope of work to complete inside the building. Non fraternization with staff, visitors, public or neighbors will be stressed with all subcontractor personnel during orientations.

All efforts will be made to ensure that property adjacent to the work area remains uninterrupted. It is anticipated that all work will be in the designated work areas. Any deviation from that will require consultation with the University of New Haven. Fraternization between construction employees and project owners, students, or visitors will not be permitted. Loud and profane language or clothing with offensive language will not be allowed on the jobsite. Extra efforts must be made to keep noise to a minimum.

Exposure to Street Traffic: All deliveries will be made at the designated gates unless otherwise directed by Superintendent. There will be exposure to live vehicular traffic and police details will be used as needed, though it is anticipated that police details will not be required. All speed limits will be obeyed and deliveries will be made as to coincide with working hours. All traffic control signage will meet University of New Haven requirements before being installed. Fire dept. access will be maintained and kept open for emergency responders.

Planning: The project team, as well as CCC safety department, will meet with each subcontractor before they start to review their Site Specific Safety and Health Program and all project specific Job Hazard Analyses. The project team shall be an integrated mix of owner, architect, engineer and Consigli Construction personnel. After reviewing the programs and meeting with the individual subcontractor, if the team is satisfied with the risk control direction, they will be permitted to begin work.

Safety Spot Recognition Plan: The purpose of this plan is to instantly recognize workers “on the spot” for working safely and to reward those workers immediately. This will assist CCC reduce the complacency of workers on all of our projects. Members from the CCC and project teams (Supers, PM, APM, PE, OPM, Architect, Owners, etc..) will be provided with $5 Dunkin Donut gift cards (or similar) prior to their walk on site. They are to present these cards to workers who are working safely and or those taking additional steps to work safely.

After issuing the card, the name and hard hat sticker number of the worker as well as a brief description of what they were doing will be documented in a log that will be maintained in the field office. This shall be completed at a minimum of three times a week. It is required that different field staff take turns in issuing the cards to workers in the field. Also required will be the communication of who is be recognized to other sub-contractors/workers through foreman meetings and daily stand up meetings. At the end of the project the sub-contractor who has had the most workers recognized will receive an appropriate acknowledgment from CCC as well as some type of reward that is to be determined by CCC field staff.

Orientation: All individuals working on this project will go through a comprehensive Safety Orientation which will cover all company safety rules regulations and procedures as well as communicating University of New Haven-specific requirements.

All personnel working on site shall have documentation of an OSHA 10 Hour Construction Safety Outreach Training minimally.

Back– End of Environmental Emergency Contact and Management Response