#2167 Johns Hopkins SNFAI

3100 Wyman Park Dr Baltimore, MD 21211

Consigli Project # 2167

Emergency Response Plan

ALL EMERGENCIES SHOULD BE REPORTED BY CALLING 911

SITE INFORMATION

This Emergency Response Plan (E.R.P.) is specifically developed for Consigli Construction (CCC) work associated with Johns Hopkins SNFAI project # 2167

SITE LOCATION

The construction site is located at 3100 Wyman Park Dr Baltimore, MD 21211. The location for the project field office will be a trailer located within the jobsite. (Reference Site logistics plan for location). The muster point for jobsite in case of an emergency evacuation will be located in front of the field office trailers. The field office will be the Emergency Operations Center (EOC).

EMERGENCY TYPE

The following situations are considered emergency response actions and should be handled in accordance with the procedures outlined in this plan.

- Serious Injury/Fatalities

- Fire/Explosion

- Structural Damage/Collapse

- Weather or Geological Event Classified as an Act of God

- Environmental Incident

- Traffic Disruption

- Utility Damage

- Illegal Activity

- Labor Problems

- Bomb Threats/Military Ordinance Unearthing

- Acts of Terrorism

When reporting an emergency, please provide the following:

• Your location, phone number, and name.

• The location of the incident (building name, floor and room number).

• Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.).

• The safest route to the incident

Crisis Response Protocol:

- Attend to the injured.

- Immediately contact Bryan Kingsbury (508)808-9359

- Post person at front gate, only allow access to emergency responders.

- Record names/addresses of witnesses

- Do not allow media on site.

- Refer all media inquiries to home office (See “Crisis Response Cards”)

A Consigli designated individual shall wait at the building site entrance to escort Emergency Services personnel as they arrive.

Subcontractors must participate in evacuation drills on a frequency determined by the Consigli Project Team. The drills will be scheduled in advance to mitigate (to the extent possible) work disruption.

The following is a list of the Chain of Command/Call Hierarchy on the project for establishing lines of succession during communication involving all emergencies.

Back– End of Emergency Response Plan

Emergency Contact Names and Numbers

| Title | Name | Contact | |

| 1 | First Call: | 911 | 911 |

| 2 | CCC Superintendent: | Marty Everson | (202)306-8831 |

| 3 | CCC General Superintendent: | Rob Soper | (202)578-3702 |

| 4 | CCC Sr. Project Manager: | Mark Senula | (202)253-7338 |

| 5 | CCC Project Executive | Phil Brault | (508)458-0362 |

| 6 | Corporate Safety Director | Bryan Kingsbury | (508)808-9359 |

| 7 | CCC Safety Manager | Matt McBride | (202)819-5897 |

Baltimore Maryland

Baltimore Police Department- Non-Emergency (410)396-2525

Washington DC Fire Department- Non-Emergency (410)396-5680

Baltimore Department of Public Works (410)887-1832

Baltimore Gas and Electric (877)778-7798

Miss Utility 811

Back– End of Emergency Contact Names and Numbers

Medical Facilities

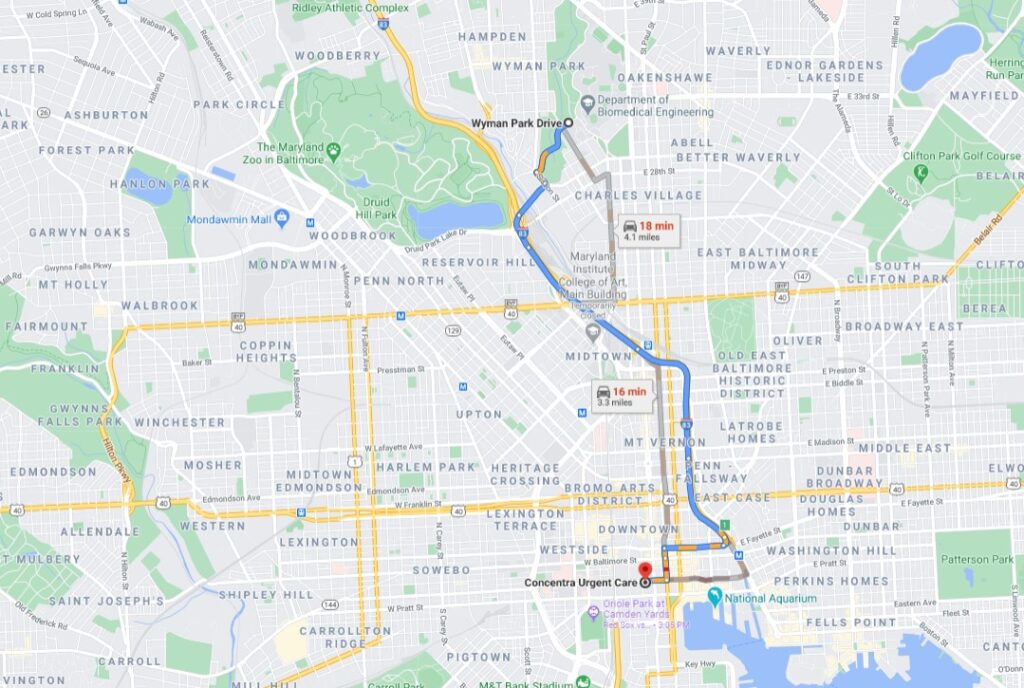

Concentra Urgent Care-Downtown Baltimore

(410)752-3010

100 S Charles Street Baltimore, MD 21201

Hours: Monday to Friday 8:00 am to 5:00 pm

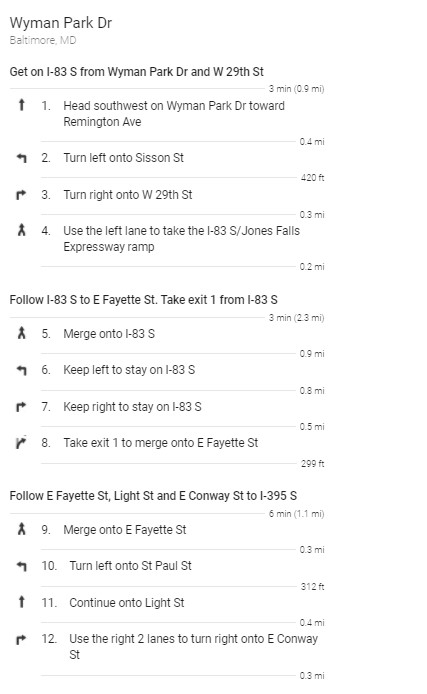

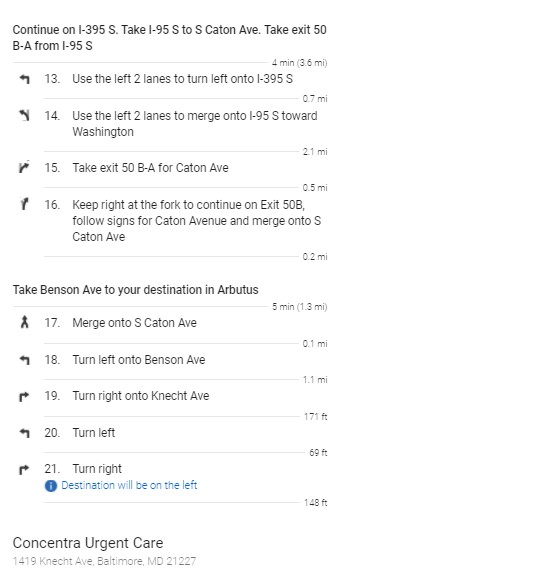

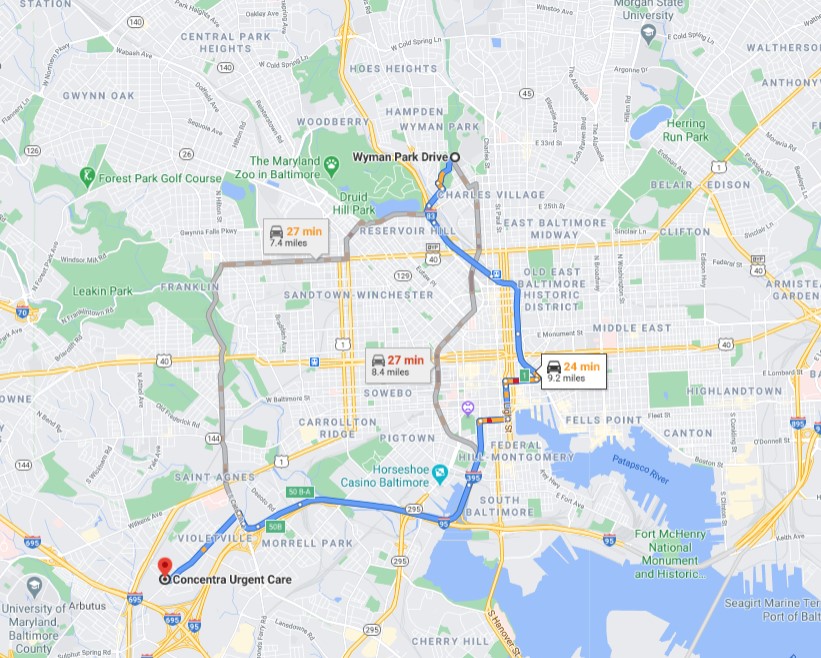

Concentra Urgent Care-Arbutus

(410)257-9595

1419 Knecht Avenue Baltimore, MD 21227

Hours: 24/7

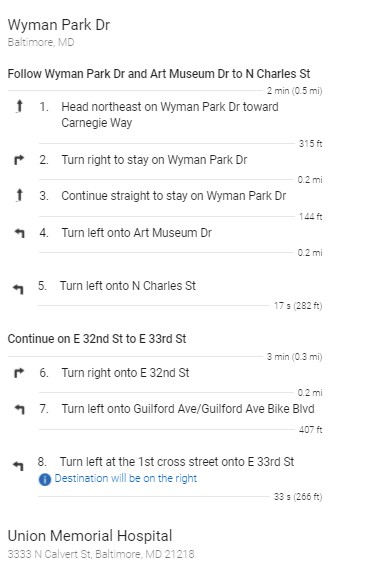

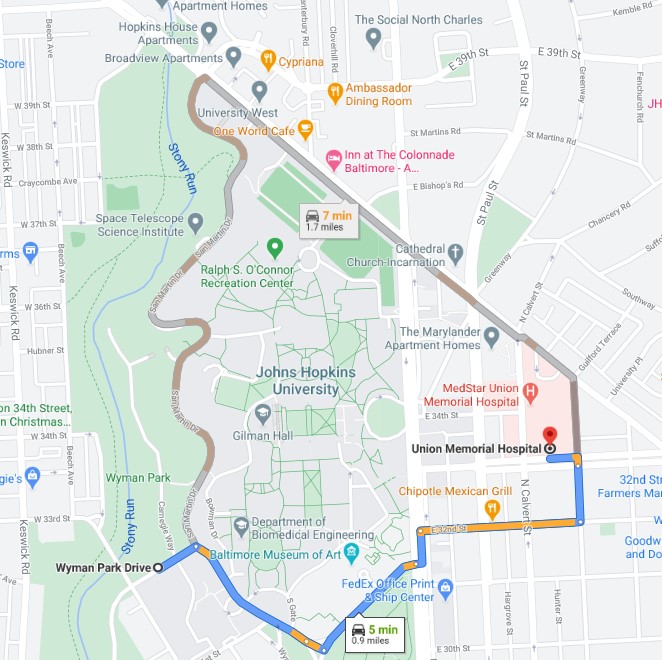

Union Memorial Hospital

(410)554-2000

3333 N Calvert St, Baltimore, MD 21218

Hours: 24/7

Back– End of Medical Facilities

Site Safety Plan

Project Specific Loss Exposures and Controls

Scope of Proposed Operations: The JHU SNFAI project consists of two conjoined structures that will serve as the new headquarters of the Agora Institute located on the campus of Johns Hopkins University in Baltimore, MD. The buildings will include offices, labs and community spaces that will support the personnel and mission of the Institute. The composite structure will be wrapped in custom curtainwall designed to achieve a LEED Platinum certification.

Purpose: The purpose of this Site-Specific Safety and Health Program is to illustrate Consigli’s approach to identifying project specific hazards and controls and how said risk is managed through a comprehensive Safety and Health Program.

S.A.F.E.: Staying Accident Free Every Day is the Safety Mission that forms the very foundation of the Consigli Safety Culture. The S.A.F.E. mission, which is supported by technology, (Predictive Solutions internal auditing instrument which identifies and defines leading indicator related information); Leadership (Empowering our team members to assure safe projects); Humanization (Protect the ones you love by protecting yourself); Jobsite Gym (Morning warm-ups, stretch and flex); Training (Integrating sub-contractors into the Consigli Safety Culture); and Lean (nothing hit the ground), is the driving force behind Consigli’ s drive to our vision – ZERO. ZERO is the philosophy that all accidents are preventable, and that no accident is acceptable. The S.A.F.E. mission is the guiding force to achieving the Consigli Safety Vision which is ZERO.

Subcontractor Safety Responsibility: Each Subcontractor working the Project will designate a Safety Representative. This individual must be a foreman or superintendent unless the Contract requires a full-time Safety Representative. The Safety Representative is responsible for the implementation and enforcement of the Connsigli Site-Specific Safety Plan and applicable OSHA/MOSH Standards, as they apply to the Subcontractor’s work/workers.

The Subcontractor’s Safety Representative must also have the authority to Stop Work if an imminent danger situation occurs. The Safety Representative (non-dedicated) may have other responsibilities (i.e., supervision of workforce, production, etc.) unless otherwise noted.

If required by the Contract, certain Subcontractors may be required to have a full time, dedicated Safety Representative on-site for the entire duration of certain work activities. The dedicated Safety Representative must have 3 years of construction safety experience, must have completed a 30-Hour OSHA Construction Outreach Program and possess a current CPR and First Aid Certification.

The Safety Representative (dedicated or non-dedicated) must also:

- Stop the Work if a hazard poses an imminent danger.

- Ensure that crew leaders conduct daily Pre-Task Plan huddles and weekly Toolbox Talks.

- Ensure that employees have received appropriate training and assist with training and retraining, as necessary.

- Be familiar with current OSHA/MOSH Standards and regulations for construction.

- Instruct employees in safe work practices and work methods.

- Ensure all employees comply with the Site-Specific Safety Plan and applicable OSHA/MOSH Standards.

- Conduct a daily informal inspection of his work area(s) and a formal (documented) weekly inspection of their work area(s). The daily inspection must be documented in a logbook or electronic recordkeeping system, and the weekly inspections must be documented with a written or electronic report, a copy of which the Safety Representative (dedicated or non-dedicated) must provide to Consigli.

- Respond in writing to safety recommendations submitted to his employer within 24 hours after receipt.

- Correct or report immediately to Consigli of any observed unsafe conditions, practices, or violations.

Worker Safety Responsibility:

- Stop the Work if a hazard poses an imminent danger.

- Comply with Consigli Site-Specific Safety Program, the Safety Program of their employer, and these General Safety and Health Guidelines.

- Attend a project safety orientation conducted by Consigli prior to commencing work on-site.

- Perform their work in a safe and productive manner, for prevention of incidents to themselves, fellow workers, general public, and property of all concerned.

- Attend and participate in daily Pre-Task Plan Meetings and weekly Toolbox Talks.

- Conduct regular job site inspections throughout the day, including without limitation, the beginning and end of shift.

- Immediately correct, without delay, unsafe acts and conditions over which a worker has responsibility and notify Consigli od f any unsafe condition that exist.

- Immediately alert his/her supervisor of any observed unsafe acts or conditions.

- Conduct and present themselves in a professional manner (no foul or offensive language, display of offensive images, participate in horseplay, fighting, use of alcohol or drugs on-site, or wearing of clothing that is torn).

- Constantly observe work conditions, equipment and tools for the purpose of preventing recognizable and foreseeable incidents.

- Report incidents and injuries immediately to his/her supervisor, without delay.

- Immediately report sexual harassment; discrimination or harassment; workplace violence; and any incident, including without limitation, injury, property damage, theft, and near miss to their immediate supervisor.

Substance Abuse: The project is committed to the principles of the DRUG FREE WORKPLACE ACT of 1988. To that end, Consigli and Subcontractors must not allow workers to report to work under the influence of any drug (controlled substance, prescription medication, or over-the-counter medicine), alcohol, or intoxicant. The Owner prohibits the use, possession, distribution, or sale of drugs (or paraphernalia) or alcohol on the project premises.

The project specific drug and alcohol testing program can be found in Attachment A.

Discrimination and Harassment:

- : Consigli has a zero-tolerance policy for any act or threat of physical violence, harassment, intimidation, bullying, graffiti, or other threatening disruptive behavior that occurs at the project. Said behavior is grounds for immediate dismissal from the project. Any employee or project worker who believes he or she has been subjected to any violation of the above shall immediately report said violation to the Consigli Project Superintendent.

- Consigli has a zero-tolerance policy for any kind of harassment including, but not limited to, race, color, religion, sex (including pregnancy) sexual orientation, national origin, ancestry, age, physical or mental disability that occurs on any Consigli Project. Whistling, leering or any type of unwanted physical contact is not allowed. Additionally, graffiti of any type, display of sexual material even animated, sexual gestures, questions, observations, comments about deficiencies, prowess, etc.… anywhere on a Consigli project is not acceptable. Said behavior is to be reported immediately to the Consigli superintendent and is cause for immediate dismissal from the project.

This policy will be reviewed by all workers during their orientation. It is the responsibility of all personnel on site to keep the work site free harassment, intimidation, coercion and from discrimination as defined by regulation, rule, or statute, including without limitation 29 CFR 1904.36.

Electronic Devices and Cameras: Televisions, radios, and Bluetooth-type audio/video devices are not permitted on the job site. Workers may not utilize a cell phone when such use diverts attention away from the activity to which they were assigned to complete, for example: equipment operation or ladder use.

Project personnel may not photograph, video, or record anyone or anything while on the project site without prior permission from Consigli representative.

Tobacco Use: Tobacco use of any kind (e.g., cigarettes, smokeless, etc.), vaping, and use of e-cigarettes are prohibited on the Owner’s property. This includes the project site.

Breaks/Lunch: Areas on the site will be designated as lunch areas. Workers are not permitted to take breaks or lunch in active work areas. Workers must properly dispose of beverage containers and food materials, including wrappers, leftovers, and containers before leaving designated break area.

If subcontractors bring in refrigerators, microwaves, and air conditioners for their own use/workers they will be responsible for making sure they are properly cleaned and maintained for the duration of the project so as not to create a health hazard. Cooking stoves, hot plates, toasters, grills or any other type of cooking device are not allowed on site. All appliances must be of commercial/industrial grade. Space heaters other than those provided by Consigli for the project are not allowed.

Permits: Subcontractors will obtain all permits through Consigli Construction. Consigli and subcontractors along with project owners will determine who’s permit will be used during construction. These permits will be posted in the field office. Permits are required for the following work activities:

– Confined space entry

– Approval to begin Steel erection

– Custody of fall protection (deck turnover)

– Fall protection removal access permit (guardrail disruption)

– Hot work

– Hazardous energy control

– Access to campus buildings

Post Incident Review: Any incident that results in a recordable injury will require a post incident review. The worker who was injured along with their foreman/Safety Personnel/PM/Sup/etc. will need to fill out Superintendent Report and attend this meeting. At this meeting they will re-emphasize their commitment to safety, determine chronology of events, identify contributing factors, identify root cause, provide improvement plan to prevent reoccurrence and discuss disciplinary actions taken (if any). Findings from this meeting will be shared/disseminated with all contractors on site to prevent reoccurrence.

Incident Investigation Reports: Consigli and subcontractor must complete and provide to the Owner and the Owner’s Representatives an Incident Investigation Report within 24 hours of knowledge of any incident (including near miss incidents) regardless of severity. If Consigli and subcontractors cannot complete and submit the Incident Investigation Report within 24 hours, Consigli must contact the Owner and Owner’s Representatives to provide an explanation as to why. If the incident investigation extends beyond the 24-hour window, a preliminary Incident Investigation Report must be filed within 24 hours, pending the submission of the complete report.

Lost Time Incident/ Return to work: After an incident resulting in a lost time, Consigli must periodically follow-up with the Employer of any injured worker until the injured worker returns to work. The Subcontractor must promptly return injured Employees to full or modified duty work (as their physical condition permits) as soon as being advised of the worker’s ability to return to work. Upon such notification, the Employer must immediately return such injured Employee to work whether or not such work is available on the Project.

Failure to promptly return a worker released to modified duty to work may result in a $1,200.00 per week fine. This fine will be issued to the employer of the injured person through a Non-Negotiable Deduct Change Order or other means approved by the Owner.

IAQ (indoor air quality): IAQ will be reviewed, if necessary, with the scope of work being conducted. If tenants occupy the building before construction complete and IAQ may be utilized.

The air will be tested for typical indicators such as but not limited to temperature, relative humidity, carbon monoxide, carbon dioxide, dust particulates and VOC’s (volatile organic compounds). Monitoring (frequency/duration) will be done in accordance with a written IAQ plan provided by a Certified Industrial Hygienist. This plan will ensure that adjoining areas have not been contaminated during abatement, demolition, and construction. Fire rated 6 mil poly barriers will be set up between any work areas and occupied spaces prior to the start of any work. Negative air machines will also be used to create a negative air flow from the occupied space to ensure that no dust and debris enter an occupied area. All equipment used on the inside to the building will be equipped with a scrubber or be of tier 4 type. Constant Co monitoring will be required if combustible engine is operated indoors. Negative air machines will also be used to create a negative air flow into the workspace to ensure that no dust and debris enter non-construction areas. Kleen sweep will be used at all times whenever sweeping is required. HEPA Vacs will be the only type vacuums allowed on site. Engineering controls will be taken to eliminate dust on site.

Identify the specific route in and out of the construction site (Approved logistics plan): For this project all deliveries and waste removal shall enter using designated access point and be coordinated with the general contractor. Also, only permitted truck routes will be used, all contractors will be responsible for adhering to truck routes and restrictions plan which will be made available to all sub-contractors. (Reference site logistics plan)

Personnel Protective Equipment (PPE): All workers will wear hard hats, safety glasses, and hi-vis clothing/vests at all times (Class II during daylight and Class III at nighttime/low visibility). All PPE must meet current ANSI standards and be inspected before use. Cut resistant gloves must be cut level three at a minimum. All personnel performing work with their hands shall be required to wear gloves that are appropriate to the task. When not performing actual work with their hand’s workers will be required to have them available for immediate use. Face shields will be required for all personnel who are performing overhead work, using metal chop saw or any type of metal grinding. All welders will be required to have hard hats with integral welding shields. Long pants and shirts with minimum 4” sleeves required at all times. PFAS systems consisting of a lanyard, harness, anchorage, deceleration device and connector or suitable combination shall be made available to workers who are exposed to a fall greater than 6 feet. Subcontractors will need to determine what type (leading edge, restraint, etc.) type of fall protection is required and make sure it inspected daily prior to the start of work. PPE will be provided to workers at no cost to the worker (except for work boots). All damaged or defective PPE will be removed from service immediately. PPE will only be used in accordance with manufacturer’s instructions.

(For further information and specifications please see section 4.5 & 13 of Consigli Corporate Safety Plan)

Additional PPE

Respiratory Protection – When tasks pose a respiratory hazard, the employer must first implement the use of engineering control measures (e.g., enclosure or confinement of the operation, general and local ventilation, and substitution of less toxic materials) to prevent atmospheric contamination. When respirators are required, subcontractors will provide CCC with a written respirator program (medical clearance, fit test, etc..) that meets requirements of 29 CFR 1910.134. The Subcontractor must provide Consigli with a copy of 1910.134 Appendix D for any worker voluntarily utilizing a filtering-face piece respirator. Further, the Subcontractor must provide and utilize whatever engineering controls are necessary to limit exposure to harmful contaminants.

(For further information and specifications please see section 25 of Consigli Corporate Safety Plan)

SIGNS, SIGNALING, and BARRICADES: Consigli and Subcontractors must perform work in accordance with OSHA/MOSH requirements and the Site Safety Rules:

1. Red tape – Imminent Danger exists. Only workers performing actual work are to be allowed within

this barricade area. The only exception for entry into a red tape area is with prior permission of the Subcontractor that established the barricade. Note: yellow caution tape must not be used on this project. If there is an area that needs access restricted, use red tape.

2. Excessive speed on the site will result in the dismissal from the site of vehicle and driver – drive to conditions. Obey speed limits, when posted.

3. Accident prevention tags must be used as a temporary means of warning workers of an existing hazard, such as a defective tool, equipment, etc. Workers must not utilize a tool that has been tagged. Tags must not be removed until the defective tool or equipment has been repaired.

4. Subcontractor must provide red tape, tags, and signs for their worker force, as may be necessary.

5. The Subcontractors must establish temporary traffic and pedestrian controls in accordance with the current edition of the MUTCD or any local jurisdictional regulation or ordinance.

6. Subcontractors must utilize 42” retro-reflective cones or other means to demarcate elevation changes, or other surface encumbrances (for example: conduits, raised manholes, pipe stubs).

7. Minor changes in elevation must be painted orange.

TOOLS – HAND and POWER: Consigli and Subcontractors must perform work in accordance with OSHA/MOSH requirements and the Site Safety Rules:

1. The Subcontractor must ensure that all original equipment manufacturer (OEM) safety devices are maintained functional.

2. Defective tools must be immediately tagged (with an ‘Out of Service’ or ‘Do Not Use’ tag, or Red Danger Tape) or disabled; or either, repaired or removed from the project.

3. The Subcontractor must ensure that workers have been trained in the proper use and maintenance of each tool that s/he may be assigned to utilize. Tools must be utilized only for purpose intended by the manufacturer.

4. Workers must use the proper tool for the assigned task.

5. Table saws must be equipped with guards when making through cuts. Table saws must be equipped with anti-automatic restart switches (to prevent a restart of the equipment if the power is interrupted). If a table saw is used, it must have an inbuilt flesh detecting emergency break and anti-kickback device.

6. Workers must provide a courtesy warning ‘Firing’ when firing a powder actuated tool (PAT). All workers utilizing a PAT must be trained by a qualified person. Subcontractors must provide Consigli with evidence of worker training.

7. Subcontractors must guard all potential pinch points (belt and pulley, chain and sprocket, screw conveyors, hoist drums) that are located with 7’ of a walking or working service. These guards must be designed to prevent accidental contact.

8. All tools, measuring tapes, etc. aloft must be tethered to the worker or otherwise secured if there is a possibility of the tool, tape, etc. falling out of the building and striking another worker, the general public, or an adjacent structure. Do not leave tools, materials, or debris on elevated surfaces.

9. Impact tools such as chisels and punches must be dressed, repaired, or replaced as the striking service becomes mushroomed.

10. Hand-held disc grinders must have the guard and handle in place.

11. Knives must be sheathed (or folder/retracted) when not in use and must be of appropriate sized and type for work. Utility knives must have self-retractable blades.

12. Each rotary hammer drill must be equipped with a vacuum system or water system to control dust.

13. Compressors must be equipped with safety check valves that will stop the air flow when a hose connection part or hose fails. Hoses must be pinned or secured with whip-checks to prevent accidental uncoupling.

14. Subcontractors must not utilize 55-gallon drums as work benches

Designated work hours (any work outside these hours must have prior CCC approval): All material host related work shall take place during regular business hours of, Monday – Friday 6:00am to 3:30pm. Any work which may need to take place outside of these hours will need to be approved by the CCC Superintendent. All deliveries must be coordinated with the CCC superintendent with at least 48 hours’ notice.

Emergency Management Response: In the event of an Emergency the construction workers shall leave the building immediately. Point of assembly/muster will be located by the site office trailers. In the Event of a DISASTER, the Superintendent or Safety manager shall instruct the construction workers to leave the site or remain in place and await further instruction. The following steps should be taken in the event of an emergency.

When reporting an emergency, please provide the following:

• Your location (3100 Wyman Park Dr Baltimore, MD 21211) phone number, and name.

• The location of the incident (floor and room number).

• Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.).

• The name and amount of the material spilled (if applicable); and

• The safest route to the spill (if applicable).

Pretask Plans: A JSA shall be conducted for each work task to be performed on a weekly basis. JSA’s shall be reviewed initially with all involved personnel performing that particular task, signed by all workers including their supervisor and filed on site.

Excavations: All subcontractors who perform excavations on site will be required to complete a daily excavation checklist. They will also obtain and maintain excavation permits required by both owner and local municipalities. All required documents will be maintained in field office. Contractors will be responsible for pre-marking excavation area for utility locator with white paint. Safe Zone of 18” (hand digging only) will be enforced with all existing utilities on site. All soil will be considered type C soil unless contractor can show otherwise. As-built drawings will be provided by contractor and indicate the location of new underground utilities, and location of any existing underground utility that have been verified in the field. If SOE are used, tabulated data/engineering for shoring and shielding systems will be obtained and available on site at all times when in use. All excavations will be inspected by a competent person on a daily basis.

- Dig Safe/Miss Notification/utility locator – permit/number/report will be posted in office.

- Copies of soil engineering and tabulated data sheets for all trench boxes or other shoring/shielding systems brought on site will be provided to CCC and be kept in construction office.

- OSHA and MOSH requirements will be strictly adhered to.

- All road plates will be in pedestrian walkways will be slip resistant.

- All unattended excavations will be protected (tape/barricade) by contractor.

(For further information and specifications please see section 19 of Consigli Corporate Safety Plan)

Demolition: Prior to the start of any demo operations, the contractor preforming demo will confirm that all utilities leading into the area have been made safe. The electrician will disconnect and lock out all electrical, the plumber will do the same with any plumbing lines, and the HVAC subcontractor will do the same on the HVAC piping and duct work. Lock out tag out will be reviewed during the pre-construction safety meetings to assure disconnect and responsibility for protection of existing utilities is safe for any construction activities to commence. In spaces where some electrical or mechanical must remain live, a color-coding system will be utilized for easy identification of live utilities that must stay active and utilities that must be removed. Any and all utilities spray painted Red are not to be touched and or need to be protected during all operations. Utilities spray painted Green are to be removed as part of the selective demolition process only after lock-out/tag-out has been confirmed and utilities tested. If any utilities are unmarked, they shall be considered live. The demo contractor will be responsible for completing CCC demo checklist prior to the start of any work in their target areas. During demolition and construction activities all personnel will wear all required protective equipment. Engineering controls will be used for any activity which may create dust.

Fall Protection: All workers exposed to a fall of 6′ or greater shall from any unguarded edge regardless of distance must be protected by guardrails safety nets or personnel fall arrest systems. Subcontractors will comply with all OSHA and OEM requirements in regard to training, equipment use, storage, inspection, maintenance, and retraining. This include, but is not limited to, steel erection, roofing, scaffold erection and dismantling, overhand brick laying and pre-cast concrete related work. Holes greater than 2” will be covered with acceptable material (3/4 plywood ½ steel) which will be secured and marked hole (cover must be able to withstand four times the intended load). At no time will equipment designed for rigging be used as fall protection. 100 % tie off required at all times when transferring between anchorage points. Termination plates will be used with all lifelines, and they will be protected from abrasion, corrosion, and sharp edges. (No knots). Lifeline anchor points (when not within sight of the user) must be labeled “Do Not Remove”. Covers will stay in place until the hole/penetration has been filled. Building perimeters will be protected with some form of fall protection if fall is greater them 6 feet. 3/8 Cable guard rail system (if used) with turnbuckles to be installed for all straight runs and any straight run over 100 feet. At no time are cable rails, cross braces on scaffold allowed to be used as fall protection anchorage point. Sub-contractors will be responsible for barricading/taping off of areas below their elevated work. All fall protection equipment must be used for its intended purpose. Self-retractable lifelines used on leading edge work must be rated for LE work and be properly labeled. Fall protection equipment id used by a welder must be fire rated. The use of safety Monitors or controlled access zones is strictly prohibited. If at any time a worker must alter/remove or disturb a fall protection system, they must first complete the Consigli fall protection removal permit (appendix CC)

(For further information and specifications please see section 13 & 16.3 of Consigli Corporate Safety Plan)

Additional Safety and Health Guidelines that will be required on this project.

Horizontal lifelines must be designed, installed, and used under the supervision of a qualified person. Except for horizontal lifelines manufactured by recognized manufacturers of fall protection, subcontractors intending to use their own horizontal lifeline systems must submit the engineering design drawings and testing data to the Consigli for review and comment 21 business days prior to the desired use. Subcontractors must provide documentation from the original equipment manufacturer (OEM) or Professional Engineer (PE) for horizontal lifelines (whether set at the feet or overhead) that will be utilized on the project. Horizontal lifelines must be utilized in accordance with the instructions provided by the OEM and/or PM.

Access ladders (portable or job-built) must be placed in ladder ways (access through a guardrail is not permitted). At each landing surface, the Subcontractor must provide an offset corral or gate to prevent workers from accidentally backing or walking through the ladder access opening.

Subcontractors are required to coordinate overhead work (or work that exposes their workers to overhead hazards) with Consigli. Subcontractors are responsible for providing, inspecting, and maintaining a falling object protection system when creating such exposure.

Subcontractors must ensure that all tools, equipment, and materials used/stored on elevated levels are secured to prevent accidental displacement/falling to lower levels.

No one may ride on top of the elevator or personnel hoist car except during erection, dismantling, and inspection operations. The Subcontractor must install a guardrail on the top of the cab to protect workers from falling or ensure that workers utilize a Personal Fall Arrest System (PFAS) if the anchor point meets OSHA requirements.

For permanent elevator construction, the Subcontractor will ensure that the false car or temporary platform is enclosed on all sides by guardrails and toe boards, in compliance with OSHA requirements and that a removable front rail is provided on the car to provide access onto and off of the car.

LADDERS and STAIRWAYS: Consigli and Subcontractors must perform work in accordance with OSHA/MOSH requirements and the Site Safety Rules:

1. Ladders, stairs, or ramps will be provided where there is a change in elevation of 19 inches or greater.

2. Workers must be trained on the safe use of ladders.

3. Ladders are required to ascend or descend truck beds and/or trailers.

4. Ladders will extend past the bearing point of the upper landing surface no less than 36 inches.

5. Ladder access points and landings must remain clear of all obstacles and obstructions to allow easy access on and off the ladder.

6. When ladders are used to access upper levels, they must be secured at the base and at the top by tying to prevent displacement.

7. Aluminum ladders are prohibited.

8. The Subcontractor must allow only competent persons to utilize portable ladders. Workers must inspect portable ladders prior to use. The Subcontractor will immediately remove or repair defective ladders.

9. Each portable ladder must be fiberglass and type 1A rated or better.

10. The Subcontractor must maintain the original equipment manufacturers (OEM) labels on each ladder.

11. The Subcontractor must ensure that ladders are used only for the purpose intended by the manufacturer.

12. Workers must not stand above the second step from the top of a stepladder, or the fourth rung from the top of an extension or straight ladder.

13. Workers must not sit on the pail shelf of a stepladder.

14. Workers must utilize personal fall arrest equipment when 3 points of contact are not possible, if an adequate anchor point is available, or scaffold should be utilized.

15. Workers utilizing a portable ladder adjacent to a perimeter or interior fall hazard that is six (6) feet or greater above a lower level (over guardrails) must utilize active fall arrest equipment if the hazard is within 1.5 times the distance away, for example: if you are on an 8’ ladder and within 12’ of the edge, you must be tied off. The Subcontractor may provide mobile scaffold fitted with guardrails, in lieu of personal fall arrest equipment.

16. Stairways having four or more risers or rising 30 inches or more must have a stair rail system 36 inches high on each unprotected side of the stairs.

17. Metal pan stairs must not be used unless the pans are filled to prevent a tripping hazard. Foam insulation and similar type materials are not suitable for temporary infill.

Roof Work: Before any work is to begin on the roof it must be determined what sections of the roof will be worked a method of fall protection will be implemented (100% tie off, guard rails, flagging etc. the use of safety monitors is not allowed) Holes greater than 2” will be covered with acceptable material (3/4 plywood ½ steel) which will be secured and marked hole (cover must be able to withstand four times the intended load). Covers will stay in place until the hole/penetration has been filled with duct or Pipe riser which extends above the deck.

Scaffold and elevated work platforms/Material Hoist: All scaffolds/material hoist supported frame, pipe staging and baker staging will be inspected daily before each shift by a competent person designated by each individual contractor who will be using it, which will be documented on Inspection tags located at the stair tower/access point to each section. If installed a scaffold/material hoist inspection checklist will be completed prior to the beginning of each shift and filed in the site office. This will be completed by the designated person from each individual contractor must complete an inspection every day the scaffold/material hoist is used by his/her employees. A scaffold inspection guide will be provided to each designated person (upon request) by Consigli Construction to aid them with their inspection. All contractors who will be erect scaffold will provide CCC with certification/Qualification of scaffold erection training as well as an erection/dismantling plan. Fall protection is required 100% during erection/dismantling. Overhead protection will be provided for all access points to any buildings located under any form of scaffolding/material hoist. Guard rails required at four feet on all mobile scaffolds. Any mobile scaffold with a work platform to base width ratio greater than two to one will need outriggers.

Subcontractors must perform work in accordance with OSHA/MOSH requirements and the Site Safety Rules:

1. Workers must be protected by a passive (guardrail) or active (personal fall arrest or restraint) system when exposed to an unprotected fall of six (6’) or greater above lower levels.

2. Unless workers are protected by effective personal fall arrest/restraint systems, all scaffold work levels must have guardrails around all open sides and edges. This includes form scaffolds. Ladder access points must be protected by a gate or equivalent fall protection.

3. All scaffolding must be altered, erected, dismantled, used and moved under the direction of a Competent Person who has received documented training appropriate for the activity s/he has been assigned to undertake.

4. The Consigli Superintendent and Safety Manager must institute a daily inspection system for scaffolds used on the project site. The Competent Person from the Subcontractor responsible for the scaffold will place a tag at each access point to the scaffold to indicate the use status of the scaffold, as follows:

a. GREEN tag indicates that the scaffold is complete with guardrails, midrails, toe boards and

planking. A green tag informs all users that the scaffold is safe to use.

b. YELLOW tag indicates that the scaffold cannot be erected with all components complete. A yellow tag informs the user that fall protection devices are required while on the scaffold with incomplete guardrails or platform.

c. RED tag indicates that the scaffold is not yet completely erected, being dismantled, or for some reason not safe and must not be used.

Note: workers must not utilize scaffold that is untagged or red tagged.

5. A Competent Person from the Subcontractor using the scaffold must initial and date the inspection tag affixed to scaffold that are permitted to be used prior to using the scaffold.

6. Subcontractors must keep all scaffold platforms free of debris and tripping hazards. Scaffold platforms must be equipped with toe boards and debris netting where there is a hazard to workers, or the public.

7. Scaffold platforms must be fully decked.

8. Platforms must be constructed of scaffold grade planks, or other suitable engineered manufactured material.

9. The use of a suspended scaffold must be coordinated with the Consigli Superintendent and Safety Manager. Scaffold inspection tags on suspended scaffold must be located on platform and at each tie-back termination point. All angulated rigging must be designed by a Professional Engineer. The Subcontractors must provide the Consigli Superintendent and Safety Manager with worker training certificates, equipment specifications and design engineering, and an erection, dismantling and use plan. The suspended scaffold design must be laminated and placed on the suspension system (located at both the platform and suspension beam) for reference.

10. The use of hooks to suspend, or tieback (to an anchor point) suspended scaffold requires engineering evaluation.

11. A stair tower must be used for access to all supported stationary scaffold higher than one frame, unless infeasible. In which case, appropriate ladder frame and or bolt on ladder scaffold access accessory must be used in conjunction with gate to protect opening.

12. Stepladders may not be used for scaffold access.

13. All OEM (and Code of Safe Practices in absence of OEM) user instructions must be adhered too.

14. Perry ‘step-up’ type mobile workstations must not be utilized as a temporary work platform beyond 24” above supporting surface. The platform must be two planks wide.

15. All mast climbing scaffold utilization must be coordinated and previously approved by Consigli (engineering will be required for tieback and shoring).

16. Scaffolds may not be loaded beyond the design capacity. Subcontractors must provide design engineering for each scaffold that has debris netting, overhead protection, and weather protection. The design must include procedures for removing and replacing connections (ties), for example.

17. No scaffold component must be altered or repaired without the consent of the manufacturer or Professional Engineer.

18. Subcontractors providing scaffolds under which workers (or the public) are to pass must be provided with 1/2” mesh, #18-gauge wire screen or equivalent between the toe board and the handrail. In no instance may masonry, tile, or similar material be stacked higher than 24” above the surface of work platforms. Materials must not be stored on scaffolds or runways in excess of supplies needed for immediate operations.

19. Original equipment manufacturers (OEM) rails must be the first choice for scaffold guardrails. Job made guardrails are acceptable where OEM guardrails are not feasible.

20. The Subcontractor must document that the structural capacity of an elevated platform is sufficient for the intended use that it plans to utilize during construction. The use of the scaffold system must be coordinated in advance with Consigli.

21. All scaffold users must be trained per OSHA/MOSH requirement

Aerial Lifts/Scissor lifts:

1. Consigli and Subcontractors must plan and coordinate the sequencing of the work

to accommodate worker access concerns and ensure that the risk of accessing work is mitigated to the extent feasible using such means as prevention-through-design efforts and proper planning and execution of the work.

2. Subcontractors must select the aerial/scissors lift that is best designed to allow the workers to safely access their work. This selection should be addressed in the Pre-Task Plans developed for each day’s tasks.

3. Each lift must have an original equipment manufacturer (OEM) operating and ANSI guide on board. Use of lifts must is limited to OEM design and instructions for use.

4. All ANSI warning and control labels must be maintained in a legible condition.

5. When working in a scissors reach or boom reach, occupants must wear a full body harness connected to a self-retracting lanyard connected to an anchor point provided by the OEM.

6. Workers must keep their feet on the lift platform at all times – they may not stand on toe boards, guardrail system, or buckets to gain height. Always close gates and chains.

7. Only manufacturer approved modifications or retrofit kits will be allowed.

8. Subcontractors are responsible to ensure that ground conditions and environment are suitable for lift use.

9. NEVER use lifts as cranes:

- Hoist only tools and personnel within the guardrails.

- Only materials that fit within the guardrails are allowed.

- Do not overload the lift.

10. Ensure that the lift has its periodic and annual inspection as required by ANSI.

11. The Subcontractor must not utilize lift equipment that creates a potentially hazardous atmosphere or unstable condition.

12. Inspect each travel area and forecast prior to and during use:

– Check for cords, holes, and changes in elevation.

– Do not drive over covers or elevated structures (e.g., vaults, decks, bridges), unless designed to support the lift.

– Do not operate lift when parameters of operating environment exceed OEM operating conditions, for example: wind, capacity, weather condition, and slope and pitch of supporting surface.

13. Cords used for charging lifts should be coiled up and unplugged when not in use. Use the appropriate size wire gauge.

Global Harmonization: All Materials and chemicals used on-site will have SDS provided before being brought onsite.

- SDS sheets on file in Consigli Construction’s project office.

- SDS sheets shall be readily accessible.

Fire Protection: Consigli and Subcontractors must follow NFPA 241 Standard for Safeguarding Construction, Alterations & Demolition as well as requirements of the local jurisdiction.

1. Subcontractors performing hot work (open flame, spark, or arc) must obtain a permit from CCC Superintendent & Safety Manager.

2. Flammable and combustible fuel must be stored in metal FM/UL listed and approved safety cans and appropriately labeled as to contents and Subcontractor’s name.

3. Any storage of flammable and combustible liquids must be within approved flammable liquid cabinets provided by the Subcontractor. These cabinets must be stored outside at a distance exceeding 50’ from the building. If stored in cargo containers or box trailers, the storage area must be well ventilated to prevent the space from becoming excessively hot.

4. All secondary containers must be labeled and disposed of properly by the Subcontractor.

Subcontractor must provide all fire watch personnel, as may be required by permit. Owner requires a 1-hour fire watch and 3-hour monitor in the existing buildings.

All secondary containers (safety cans, compressed gas bottles, for example) must be secured to prevent accidental spillage, damage from falling objects, and / or mobile and mechanized equipment.

5. Secondary containment must be provided for all containers that are 55 gallons or greater in capacity. The secondary containment capacity must equal 110% of the largest container placed inside the containment system. The containment must be covered to prevent storm water contact and accumulation.

6. A 20 lb. ABC fire extinguisher must be located at each storage location.

7. Each fire extinguisher must be tagged and properly inspected.

8. The Subcontractor must be responsible to store flammable and combustible material(s) in accordance with manufacturer’s recommendations and local regulations.

9. All tarpaulins and plastic sheeting utilized (for temporary enclosures) on the project must be marked fire retardant.

10. All workers must use and inspect fire extinguishers per NFPA 10.

11. Adequate room must be maintained around area and task lighting and heating units.

12. There must be no open or barrel fires permitted on this project.

13. The Subcontractor supplying temporary standpipes must protect connections with temporary metal covers or caps and mark each standpipe location at the fire department coupling appropriate signs.

14. Propane must not be stored within the building or overnight on the roof of the building.

15. CCC Superintendent and Safety Manager must contact the local fire department if temporary heat is necessary to determine the need for a permit.

16. Flammable and combustible liquids may not be transferred with air pressure.

17. A 20 lb. ABC fire extinguisher must be immediately available with any hot work activity.

18. Combustible materials (oil-soaked rags, paper, etc.) must be stored in a metal container with self-closing metal lid.

19. Barbecue grills and turkey fryers are not permitted on-site unless permission is given by the Owner or Owner’s Representative.

WELDING, CUTTING and SOLDERING: Consigli and Subcontractors must perform work in accordance with OSHA/MOSH requirements and the Site Safety Rules:

1. Burning and cutting equipment must be inspected before each use – Defective equipment must not be utilized.

2. All compressed gas cylinders must be marked with the Subcontractor’s name. The marking must be weatherproof.

3. Carts used to hold and move oxygen and acetylene cylinders must be equipped with non-combustible 5’ high air-gapped ½-hour rated fire-rated barrier.

4. Hoses and manifolds must be removed from the tanks and the tanks tightly capped after their use at the end of the day. Tanks may remain in carts for 24 hours after use, after that period the tanks must be removed to an appropriate storage area.

5. Compressed gas cylinders must be turned off and lines purged prior to break in activity (for example: coffee and lunch) and at the end of the day. Valve keys and / or wrenches must be attached to the fuel bottle.

6. Fuel gas hoses and welding leads must be maintained to prevent a tripping hazard.

7. Welders must wear eye protection under welding helmets. Hard hats must be worn by welders.

8. Flashback arrestors must be installed per the manufacturer of the equipment.

9. Subcontractors must ensure that welders wash their hands prior to eating or drinking.

10. Only electric welding machines must be utilized in an enclosed space. The Subcontractor must provide a separate power disconnect.

11. Hot electrodes must be dipped in water prior to being discarded.

12. Oxygen must not be utilized by a worker to blow off clothing or for ventilation.

13. All compressed gas bottles (irrespective of size) must be capped and stored in a vertical secured (with steel chains or wire) position in a well-protected and well-ventilated location in accordance with local jurisdiction requirements. ABSOLUTELY no storage is allowed in gang boxes, storage trailers or field offices. Empty cylinders must be marked ‘MT’.

14. Subcontractors must provide whatever controls are necessary to protect other workers (and public) from arc flash and molten metal created during welding and cutting operations.

Electrical: Consigli and Subcontractors must perform work in accordance with OSHA/NFPA70E requirements and the Site Safety Rules:

1. All cords and tools onsite must be protected by GFCI devices, either at the source or by use of a GFCI ‘pigtail’. Check with the electrician if you are unsure whether a circuit is protected.

2. Inspect all cords and tools before use – damaged cords and tools are dangerous to you and others and will be removed from service if discovered.

3. DO NOT access circuit panels unless you are appropriately trained and authorized to perform such work. Keep the area three (3) feet around the panels clear.

4. Subcontractors must maintain cords and tools so that they are off the floor, wherever possible.

5. NEVER run cords through pinch points or over sharp edges (such as the bottom track of a steel stud wall).

6. D0 NOT run over cords – be sure to stow cords properly when not in use.

7. NFPA 70E work practices must be observed. The Subcontractor performing the work or with exposed employees must provide assessments, proper equipment, PPE, and training. The Subcontractor whose employees are covered by NFPA 70E must provide documentation of the training required in the standard to the Consigli Superintendent. The Consigli Superintendent must verify that proper controls are in place.

8. Temporary wiring must conform with and be installed in accordance with the most current version of the National Electrical Code.

9. All electrical enclosures (j-boxes and cabinets) must be inspected to ensure that knockouts are filled when not occupied. Each cabinet must have voltage rating label.

10. All disconnects, and circuit panels must be labeled with voltage and function. A breaker schedule must be posted inside each circuit panel. A label must be placed at each receptacle, or tool connection to identify the controlling circuit panel.

11. The bulbs of temporary lighting must be guarded to prevent accidental damage and / or thermal exposure.

12. All fish tapes must be non-conductive. No fish tape must be placed into a live panel or electrical enclosure.

13. Portable lights must have LED bulbs.

14. Flat cords are not permitted on the project.

15. Workers must maintain operational clearance distances from overhead power lines.

16. Cords must be 12 gauge or better.

17. The electrician will be responsible for all temp power and any general temp lighting that may be needed. Subcontractors will be responsible for task lighting in the event that lighting above the OSHA standard is required for a particular work task. The electrician will coordinate all lock out tag out procedures. All temporary power for the project will be installed on protected and dedicated circuits with 100% GFCI protection.

18. GFCI will be tested by the electric contractor to assure proper function with a logbook filed with CCC monthly.

19. No live electrical work will be conducted.

Crane: All cranes will require independent annual 3rd party inspections. Crane work will be permitted for operation only after detailed lift plans (14 calendar days/21 calendar days for critical lift plan) are submitted and reviewed by Consigli. All critical lift meetings will be attended by all parties including owner representation. A logistic plan will be required with each lift plan. Contractors will be responsible for creating a plan for each crane location which will include the unloading of trucks. It is anticipated that most cranes to be used on site will be hydraulic. In the event that a lattice boom crane is utilized (unlikely), then the crane must get an on-site 3rd party inspection once the crane is assembled, prior to operation.

There is a requirement to assure that certified riggers, signalmen, and crane assemblymen training be documented and provided to CCC. All picks are to be done by a licensed operator (State/NCCO). Critical picks are defined as those involving 2 cranes lifting simultaneously, a pick that is over 75% of capacity, a pick that involves the lifting of a man basket, or any other lift that is deemed to involve special conditions. Location and set up will be reviewed with crane operator prior to set up and pick. All lifting operations will require that the operator and any involved contractors follow the steps listed below as well as in CCC Crane Safety policy.

1. All Hoisting equipment will have an up-to-date 3rd party inspection certificate with the equipment which will be copied and filed in the office trailer.

2. All lattice boom cranes will have an independent 3rd party inspection completed each time one is set up on the project, after assembly and prior to operation.

3. All equipment operators will be required to have in their possession all appropriate licensing and training as required by OSHA, State and local municipality. All crane operators must be evaluated by their employer and documentation of the employer evaluation included in the lift plan.

4. All underground vaults and existing utilities will be marked out before any crane is set up.

5. Documented daily rigging and crane inspections and filed with CCC weekly.

6. if required obtain FAA permit for crane set up (flag. beacon, etc.)

7. Documented rigger and hand signalman training will be provided.

(For further information and specifications please see section 19 of Consigli Corporate Safety Plan)

MATERIAL HANDLING, STORAGE, USE and DISPOSAL: Consigli and Subcontractors must perform work in accordance with OSHA/MOSH requirements and the Site Safety Rules:

1. Subcontractors must provide each worker with instruction on how to perform manual material handling.

2. Persons performing rigging operations (including inspecting rigging) must be trained in accordance with applicable ANSI A10.42 and ASME B30 industry consensus standards. Riggers must be qualified commensurate with their rigging responsibilities and in accordance with the current ANSI A10.42 industry consensus standard.

3. Except where the Owner expressly permits multiple lift hoisting operations for steel erection, multiple lifts for other items (e.g., rebar bundles, portable toilets) are prohibited.

4. Palletized loads (e.g., masonry and bricks) must be wrapped in plastic or banded to prevent material from falling during transportation and storage.

5. Winches must not be utilized to hoist material.

6. All equipment and devices utilized for overhead lifting must be marked in accordance with the

applicable American Society of Engineers (ASME) industry consensus standard.

7. Subcontractors must not sling pallets, unless the pallet is specifically designed for such activity.

8. A Competent Person designated by the employer must inspect ALL rigging before use – even hand lines used for hoisting tools.

9. The Subcontractor must provide Consigli with engineering and 125% proof load test results for each piece of custom hoisting (and rigging) equipment.

8. 5-gallon buckets or 55-gallon drums must not be utilized to hoist materials or supplies.

9. Sorting hooks may not be used for overhead lifting and may only be utilized to move material from a truck to the ground or from spot to spot on the ground.

10. Personal fall arrest equipment must not be utilized for material handling.

11. Material handling equipment must be utilized and maintained in accordance (and for the purpose intended) with the OEM operating instructions.

12. The Subcontractor must ensure that material handling equipment is utilized by properly trained and licensed (when required by jurisdiction) workers.

13. Subcontractors must ensure that workers installing chemical fasteners are certified by the

manufacturer.

14. Subcontractors must coordinate the storage area established for compressed gases (that are not associated with temporary heating or torch cutting) with Consigli. The cylinders must be secured in a vertical position with non-combustible material (i.e., chain, wire rope). Each cylinder must be marked with the Subcontractor’s name.

Confined Space: All confined spaces to be permit required until the potential hazards (atmospheric, physical, etc.) inside the confined space are evaluated. Consigli Superintendent and Safety Manager must be aware of all confined space entries and review confined space entry procedures with the Subcontractor entering the confined space.

1. Each Subcontractor must coordinate all confined space work activities in advance with the Consigli Superintendent and Safety Manager.

2. Each Subcontractor must use a Confined Space Pre-Entry Checklist/Permit that the Consigli Superintendent and Safety Manager must verify prior to any confined space entry taking place.

3. The atmospheric conditions of confined spaces must be monitored prior to entry. Continuous monitoring will be a condition of entry. The testing instrument must be calibrated prior to use and utilized by a qualified individual.

4. Subcontractors must provide all equipment, including without limitation atmospheric monitoring equipment.

5. The Subcontractor is responsible for providing for rescue per 29 CFR 1926 Subpart AA. If local fire department, or third-party rescue service is utilized, the Subcontractor must schedule an on-site coordination meeting.

Steel Erection: Any subcontractor associated with the structural steel erection will comply with the following. Provide proof of training of subpart R training as well as fall protection training for all workers will be required before start. Consigli will release documentation when column footings reach 75% of breaking strength. Once this has been achieved, CCC will furnish to the steel erector the “approval to begin steel erection form”.

The steel erection sub will be required to submit a detailed erection sequencing plan that illustrates crane locations and capacity of cranes at those locations. Fall protection will be determined for connectors after pre-construction meeting with sub is held. Fall protection will be required at 6’, at all times during steel erection.

Once decking is complete and all required fall protection is installed, CCC will walk the area with the steel erection subcontractor. Provided all required elements of fall protection are in place, CCC will complete and give a copy of the “custody of fall protection” form to the steel erection subcontractor. Maintenance and overall responsibility of the fall protection system will fall to CCC.

Materials Management: Materials management, getting materials into and out of the project, will be a challenge that needs to be adequately planned. An Activity Hazard Analyses shall be done on all materials that will be entered and removed from site.

Traffic Control plan will be Coordinated with Consigli Superintendent.

Lean requirements/Materials Management/Housekeeping: Getting materials into and out of the project will be a challenge that needs to be adequately planned. All deliveries are to be scheduled with the CCC Superintendent. A comprehensive Job Safety Analysis shall be done on all materials that will be hoisted and placed into the building. Only materials which will be used/installed within three days’ time will be delivered to the site. Attention must be paid to structural analysis in regard to loading existing floors with material and equipment. Listed below are additional Lean requirements.

No materials shall be delivered to the site earlier than 3 days before said materials are to be installed/put into place. If materials have to be delivered before that 3-day time period, subcontractor shall get prior approval from Consigli Superintendent. Because of this, notification / scheduling is required for all deliveries to the site. Subcontractors must notify Contractor at least 24 hours in advance. Contractor has the right to refuse any deliveries not properly scheduled or due to logistical constraints as necessary.

All subcontractors’ delivered materials shall be placed on wheeled carts, wheeled racks or in wheeled bins so as to necessitate easy relocation in the event materials need to be moved. Carts, racks, or dollies shall not exceed manufacturers intended weight loads. Materials/tools can be delivered and stored on pallets only if pallet jacks are delivered simultaneously with said delivery to provide for ready mobility. Additionally, pallet jacks need to remain in immediate area. Each subcontractor will need to supply their own pallet jacks for their own materials and keep their pallet jack within reasonable distance at all times.

All workstations shall be provided with wheeled trash bins for immediate placement of all debris produced as a part of the subcontractor’s operations. All trash will be immediately placed in wheeled containers provided by Consigli.

All subcontractors shall use rubber wheeled carts when moving material or removing trash from a building. Any damage caused by the Subcontractor shall be repaired at the cost of the Subcontractor. Back charges will be appropriately assessed for the cost of the repairs. No trash or materials shall be left on the floor.

Subcontractors shall, where feasible, elevate all electrical extension cords, hoses, or cables – removing them from all walking/working surfaces. Electrical Cords, when elevated shall be supported or suspended in a manner that does not subject them to damage.

Storage of delivered materials in cardboard containers shall be discouraged. When materials must stay in cardboard containers, said containers shall be removed from the projects immediately after product is unpacked.

Subcontractor will participate in schedule development meetings as required by Consigli.

Back– End of Site Safety Plan

Environmental Emergency Contact and Management Response

Bat and Bird Feces Removal: Subcontractors must instruct workers to stop work if bat or bird feces are encountered, so that a work plan can be established. The Subcontractor must provide Consigli with an abatement work plan, which addresses the following means and method (how will Subcontractor perform work to prevent spores from becoming airborne, or prevent the migration of airborne spores), respiratory protection, protective clothing, hygiene practices for workers, communication of hazards, housekeeping, recordkeeping and competent person(s).

Controls may include: area isolation (to prevent migration of spores); use of water mist to dampen material during abatement (this will suppress spores from becoming airborne); level C PPE (Tyvek suit, impervious gloves, half-face piece respirator with HEPA filter or full-face piece for enhanced eye protection, and goggles); good hygiene practices (hand washing, donning and doffing PPE outside of work area, no eating, drinking or smoking prior to removal of PPE and washing, instructed not to touch face prior to removing PPE); and decontamination of PPE and tools, bagging and disposal of feces upon abatement.

Lead Paint: The following rules have been adopted on this project due to the possible presence of lead:

- Affected Subcontractors must provide Consigli with a work plan, which addresses the following: regulated areas, exposure assessments and monitoring, methods of compliance, respiratory protection, protective clothing, hygiene facilities and practices for workers, communication of hazards, housekeeping, medical surveillance, recordkeeping, and competent person(s). This plan must be reviewed by a Certified Industrial Hygienist.

- The Subcontractor must provide Consigli with all air monitoring test results within 24 hours of their receipt.

- The Subcontractor must provide Consigli with a daily report listing the names of workers that entered the lead regulated area, along with the quantity and type of materials that were removed.

- Appropriate barricades and signs must be provided and maintained in a legible condition.

- All enclosures, regulated waste storage areas, and barricades must be maintained by the Subcontractor.

- The Subcontractor must ensure that workers do not leave the worksite wearing contaminated clothing.

Consigli Construction does possess historical data to show that drilling, sawing, light demo, installation of hangers, hanging sheetrock, fastening, and carpentry do not put the employee above the action level. Despite this additional monitoring will be done. An exposure assessment will be done for any task on painted surfaces prior to the work taking place. This does not mean that lead could not still be found in/on other surface/areas, caution must be used when working and if any workers identify any potentially hazardous substances, then they should stop and notify their supervisor immediately.

Asbestos: There will be no scope of work involving asbestos. This does not mean that asbestos could not still be found in other areas. Caution must be used when working and if any workers identify any potentially hazardous substances, then they should stop and notify their supervisor immediately, who in turn, will notify the CCC Superintendent.

If at any time a worker come across a material, he/she cannot confirm as asbestos free they shall notify their supervisor immediately. All asbestos containing material will be fully removed by a licensed and regulate contractor under an asbestos removal plan which must be submitted and approved, all abatement work will be completed by a licensed Asbestos abatement contractor. All disposals will be done in compliance with State and Federal Regulations. Any worker who discovers any suspect material which cannot be confirmed as non-asbestos containing shall immediately notify CCC superintendent who will then secure the area (if needed) and have the suspect material tested and treated as needed. Clearances will be provided to Consigli by Industrial hygienist prior to any workers entering the area.

If asbestos is discovered, follow the following guidelines along once HAZMAT testing is conducted.

1. Affected Subcontractors must provide Consigli with a work plan, which addresses: regulated areas, exposure assessments and monitoring, methods of compliance, respiratory protection, protective clothing, hygiene facilities and practices for workers, communication of hazards, housekeeping, medical surveillance, recordkeeping, and competent person(s). This plan must be reviewed by a Certified Industrial Hygienist.

2. Subcontractors must provide Consigli with all air monitoring test results within 24 hours of their receipt.

3. Subcontractors must provide Consigli with a daily report listing the names of workers that entered the regulated abatement area, along with the quantity and type of materials that were removed. Each Subcontractor must provide Consigli with a copy of all shipping manifests associated with regulated waste, as may be applicable.

4. All enclosures, regulated waste storage areas, and barricades must be maintained by the Subcontractor

Polychlorinated Biphenyl’s (PCBs): At no time, shall a worker disturb any material he/she cannot readily identify. If they come across a material, he/she cannot confirm, they shall notify their supervisor immediately. If PCBs are found in existing finishes. All suspect PCB containing finishes which test for more than 50 ppm it will be considered PCB containing material and will be disposed of in accordance with all local, state and federal regulations.

Light ballast that are not labeled “NO PCB’s” will be considered PCB containing, All PCB containing material shall be removed and disposed of in accordance with all local, state (MEMEP Special waste management rules 06-096-CMR 400) and federal regulations.

A hand wash station will be established and maintained for the project duration.

At no time, shall a worker disturb or move a material he/she cannot readily identify, if they discover such a material, they must notify the Superintendent immediately.

Mercury: All fluorescent lamps/thermostats are presumed to contain mercury vapor, which is a hazardous substance. Mercury-containing lamps associated with fluorescent light fixtures in areas designated to be renovated will be treated accordingly. All florescent bulbs removed during renovation will be collected, stored properly on site and giving to WHCC so as to be recycled or disposed of properly.

Freon/Glycol: All Freon/Glycol materials will be removed from equipment and stored per manufacturer’s recommendations before it is disturbed. All workers who will be working with the above-mentioned materials must provide CCC with certifications or qualifications. If not re-used, a disposal manifest will be provided to CCC.

Silica: Any activity which can produce silica dust will use engineering controls to keep dust to a minimum. There will be no dry cutting of any masonry material allowed; if water can not be used then a dustless vacuum system consisting of a HEPA dustless vacuum system will be used in conjunction with an exposure assessment if table 1 cannot be complied with. Prior to the project going full scale an exposure assessment of a worker grinding, demolition and cutting masonry while using HEPA system will be done so as to establish the silica exposure level if water cannot be used to eliminate or table 1 complied with. No respirators will be issued to CCC workers without the express consent of the Consigli Safety department. Nuisance mask like an N95 if used will be on a voluntary basis and at no time will these types of masks be issued to the workers. Any activity which can produce silica dust will use engineering controls to keep dust to a minimum. A written exposure plan must be developed for all silica producing tasks that clearly defines the following:

1) A description of the tasks in the workplace that involve exposure to respirable crystalline silica.

2) A description of the engineering controls, work practices, and respiratory protection used to limit employee exposure to respirable crystalline silica for each task.

3) A description of the housekeeping measures used to limit employee exposure to respirable crystalline silica.

4) A description of the procedures used to restrict access to work areas, when necessary, to minimize the number of employees exposed to respirable crystalline silica and their level of exposure, including exposures generated by other employers.

Mold: Mold issues are not anticipated to be prevalent on this project, however if mold is discovered Consigli’s mold remediation policy will be implemented and followed.

Noise: Noise exposure will also be a concern, so all deliveries must be coordinated with CCC Superintendent to limit their impact on the surrounding areas. Normal working hours will be between 6am and 3:30pm; any contractor who may need to work late must first seek approval from the CCC Superintendent. Interior work will take place between 7pm -3am. Noise levels will be monitored if high levels of noise are found to exist or could be expected to assure that noise levels do not exceed acceptable OSHA levels. Consigli permissible noise policy and procedures will be followed.

Equipment issues: All operators will be required to have in their possession all appropriate licensing and training as required by OSHA. All safety devices and warning alarms must be in good working order and all leaks are to be repaired immediately. All equipment will be used in accordance with the manufacturer’s recommendations for safe usage and have its operator’s manual as well as an extinguisher with it at all times.

Equipment checklists are required to be filled out daily and submitted to Consigli project team.

Exposure to the Visitors and Staff: During the different phases of the project. Non-fraternization with staff, visitors, will be stressed with all subcontractor personnel during orientations.

Loud and profane language or clothing with offensive language will not be allowed on the jobsite. Extra efforts must be made to keep noise to a minimum.

Any questions regarding the project or jobsite are to be directed to the Consigli superintendent.

1. A visitor is any individual that has not received a project orientation.

2. Consigli will have on the fence stating that all visitors must complete Covid 19 daily screening and then report to the Consigli field office.

3. All visitors must register with the (complete visitor form) Consigli prior to entry to the site and be escorted by personnel who have completed the orientation.

4. Appropriate personal protective equipment will be provided to visitors’ (e.g., hard hats, safety glasses, and safety vests and gloves). PPE will be located at the Consigli field office trailer and shall be returned after use. All returned PPE will be properly cleaned before being re-issued.

Adjacent Property: All steps will be taken to limit the effects of the project on the surrounding community. A traffic logistics plan will be created by Consigli project team.

Exposure to Street Traffic: All deliveries will be made at a designated location unless otherwise directed by Superintendent. Their will be exposure to live vehicular traffic and police details will be used when required. All speed limits will be obeyed, and deliveries will be made as to not coincide with other scheduled deliveries. All traffic control signage (if needed) will meet CCC and town requirements before being installed. Coordination with CCC will be required when any equipment will be set up/used in the street/parking lot. Fire department access will be maintained and kept open for emergency responders.

Utility Exposures: All utilities entering the site will be marked prior to the start of demolition. Written notification of this work will be provided to Consigli Construction prior to commencement of Demolition work.

Planning: The project team as well as CCC safety department will meet with each subcontractor, before they start to schedule a Pre-Construction Safety Planning meeting to review their Site-Specific Safety and Health Program and all project specific required documentation. The project team shall be an integrated mix of owner, architect, engineer and Consigli Construction personnel. If, after reviewing programs and meeting with the individual subcontractor, the team is satisfied with the risk control direction, they will be permitted to begin work.

Additional Controls: Prior to stat of any work, all personnel involved in the project, including project managers must be:

- 1st thing 1st day on the site workers will complete a safety orientation provided by CCC. Once completed workers will be given a hard hat sticker with their individual number which will be displayed on the outside of the hard hat.

- At this time workers will notify Consigli of any allergies or medical condition that may require emergency treatment. This information will be placed on a sticker provided by CCC that will be placed on the inside of their hard hat.

3. All workers will provide Consigli with an OSHA 10 card and Foreman/Supervisor with an OSHA 30.

The SDS sheets associated with any hazardous substances to be used will be maintained by the superintendent in a marked three ring binder.

Site Safety Meetings will take place at the beginning of the project and at least once every week thereafter. These meetings will consist of toolbox talks with Consigli Construction Co., Inc. personnel on site. Sub-contractors will be responsible for their own safety meetings. Superintendent will complete a daily site safety walk to identify and correct potential hazards.

All emergency telephone numbers will be posted in the Consigli Field office and throughout the site.