Consigli Project # 2614

60 Guest Street, Boston, MA, 02135

Emergency Response Plan

ALL EMERGENCIES SHOULD BE REPORTED BY CALLING 9-1-1

SITE INFORMATION

This Emergency Response Plan (E.R.P.) is specifically developed for Consigli Construction work associated with the 60 Guest Street project – job #2614

SITE LOCATION

The location for the project field office will be located inside of 40 Guest Street, Boston, MA 02135. (notifications of any changes will be provided). If otherwise determined, the field office will become the Emergency Operations Center (EOC).

EMERGENCY TYPE

The following situations are considered emergency response actions and should be handled in accordance with the procedures outlined in this plan.

- Serious Injury/Fatalities

- Fire/Explosion

- Structural Damage/Collapse

- Weather or Geological Event Classified as an Act of God

- Environmental Incident

- Traffic Disruption

- Utility Damage

- Illegal Activity

- Labor Problems

- Bomb Threats/Military Ordinance Unearthing

- Acts of Terrorism

When reporting an emergency, please provide the following:

- Your location, phone number, and name

- The location of the incident (building name, floor and room number);

- Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

- The safest route to the incident.

Crisis Response Protocol:

- Attend to the injured

- Immediately contact Bryan Kingsbury (508)808-9359

- Post person at front gate, only allow access to emergency responders

- Record names/addresses of witnesses

- Do not allow media on site

- Refer all media inquiries to home office (See “Crisis Response Cards”)

Emergency Procedures: A Consigli representative will be dispatched to the Main entrance(s) of the building to meet the responding Emergency Personnel and advise the individual in charge of the location of the incident as well as any chemicals or hazardous substances that may be present on any of the floors. Safety Data Sheets will be readily available if needed by the Boston Fire Dept.

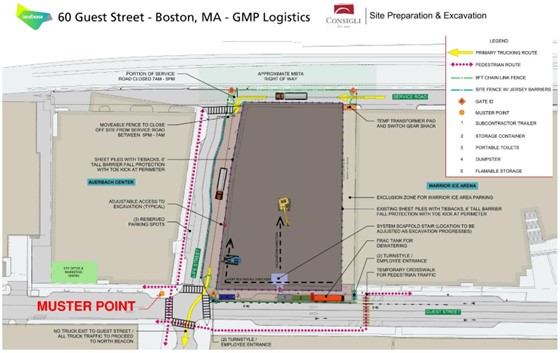

In the event an evacuation is required all personnel at this job site will follow the building/site evacuation plan and meet at the designated Muster Point (Located on the corner of Guest St. and Life St. (see photo below). The foreman for each company will meet at that location and take a head count of their staff and report to Consigli Superintendent. If for some reason a worker is unaccounted for, the fire department will be notified of the last location where the worker was observed.

The following is a list of the Chain of Command/Call Hierarchy on the project for establishing lines of succession during communication involving all emergencies.

Back– End of Emergency Response Plan

Emergency Contact Names and Numbers

| 1. First call: | 911 Fire or Police |

| 2. CCC Superintendent: Jeff Costa | (774)573-2953 |

| 3. CCC PM: Jared Cianciolo | (203)906-7370 |

| 4. CCC General Superintendent: Gabe Mater | (774)573-4892 |

| 5. CCC PX: Vin Moran | (857)492-4584 |

| 6. CCC Project Safety: Nick Nowak | (774)462-7468 |

| 7. Corporate Safety: Bryan Kingsbury | (508)808-9359 |

Additional Construction Contacts:

- Lendlease– Joel Pickering (917)440-4613

- Consigli Construction, Inc. – Boston Office (617)259-1007

Environmental Consultant: ALG Environmental

Allen Grinnell (603)557 2801

Local Emergency Services.

| Boston Police (non-emergency) | (617)343-4260 |

| Boston Fire Department (non-emergency) | (617)343-2880 |

| Boston Inspectional Services | (617)635-5300 |

| Dig Safe | 811 |

| Eversource Electric | (800)592-2000 |

| Eversource Gas Co | (800)592-2000 |

Back– End of Emergency Contact Names and Numbers

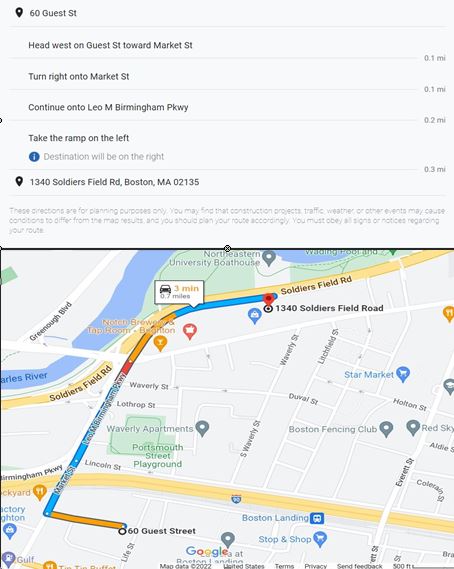

Medical Facilities

OHSTC – Nancy Hughes

1340 Soldiers Field Road, Brighton MA 02135

Phone: (866)510-3002

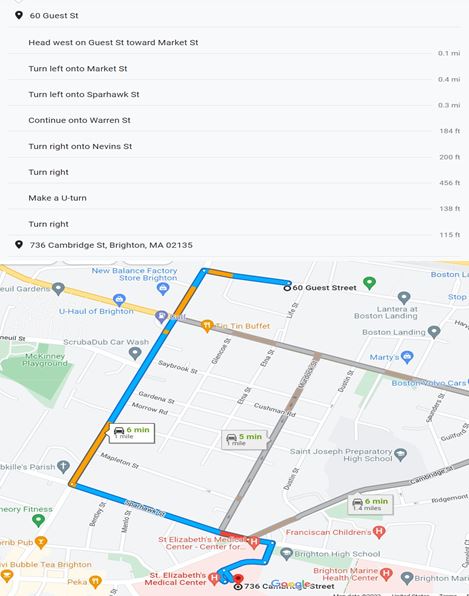

St. Elizabeth’s Medical Center (emergency)

736 Cambridge St, Brighton, MA 02135

Phone: (617)789-3000

Back– End of Medical Facilities

Site Safety Plan

Project Specific Loss Exposures and Controls

Scope of Proposed Operations: The 60 Guest Street project involves the Core and Shell Construction of a 335,000 SF (520,000SF with parking) steel frame, 9-story building. 60% Office/40% Lab: Office building with a two-story mechanical penthouse, 2 levels of underground parking with underpinning and hangar steel over 80 Guest St interface. The façade of the building will be cladded with a unitized glass and metal panel Curtain wall system.

The overall project scope begins with the installation of steel sheet piles around the perimeter of the project. Following sheet pile install, site work will commence, consisting of drilled micropiles, installing bracing/tiebacks to support deep excavation, and bulk excavation approximately 25 feet in depth. Subsequent work will include concrete placement, core and steel erection, followed by curtain wall and roof installation, as well as the installation of MEP equipment. Project duration is anticipated to be 26 months. The parcel has property lines along Guest St, Life St, and a service road on the north side of the project.

Construction traffic will pull into and exit the site via Life Street. Access to the project will be limited to the turnstiles located on Life Street and Guest Street, with badges required for admittance.

PURPOSE: The purpose of this Site Specific Safety and Health Program is to illustrate Consigli’s approach to identifying project specific hazards and controls and how said risk is managed through a comprehensive Safety and Health Program.

- .: Staying Accident Free Every Day is the Safety Mission that forms the very foundation of the Consigli Safety Culture. The S.A.F.E. mission, which is supported by technology, (Predictive Solutions internal auditing instrument which identifies and defines leading indicator related information); Leadership (Empowering our team members to assure safe projects); Humanization (Protect the ones you love by protecting yourself); Jobsite Gym (Morning warm-ups, stretch and flex); Training (Integrating sub-contractors into the Consigli Safety Culture); and Lean (nothing hit the ground), is the driving force behind Consigli’ s drive to our vision – ZERO. ZERO is the philosophy that all accidents are preventable and that no accident is acceptable. The S.A.F.E. mission is the guiding force to achieving the Consigli Safety Vision which is ZERO.

Lendlease GMR’s: The 60 Guest Street project will be implementing Lendlease’s Global Minimum Requirements for EH&S. These Global Minimum Requirements provide a focus on front-end planning, risk and innovation across the operational lifecycle and creates a simpler and more effective framework for managing EH&S. These Global Minimum Requirements will be reviewed with all subcontractor personnel and are included at the end of this plan.

Designated First Aid Plan: All injuries no matter how minor must be reported to Consigli Superintendent immediately. The Superintendent will then report all injuries to the CCC Safety Director/Safety Manager. Following initial notification, Consigli will immediately notify Lendlease site-safety representative, Jefell Campos, to ensure rapid communication to Lendlease Management. A fully stocked first aid kit, blood borne pathogens kit, stokes basket, and eye wash stations. shall be maintained on the project site. Only properly trained personnel will administer first aid. Consigli Construction shall follow Site Safety Plan for first Aid.

Report all incidents to the Safety Director: Bryan Kingsbury (508)808-9359

CCIP: This project will be run under a Contractor Controlled Insurance Program (CCIP). Consigli will assume the risk of the project by incorporating contractors into this insurance program. Contractors with an EMR (Experience Modification Rating) above 1.01 will be required to have bi-monthly 3rd party safety inspections completed and copied to Consigli. Any company with an EMR over 1.20 must have a full-time dedicated safety representative on-site at all times. Any contractor with an EMR over 1.25 must be approved by Consigli Safety Director prior to being contracted to work on- site. Furthermore, any contractor with 30 or more workers on-site must have a full-time dedicated safety reprehensive on-site. Some contractors may be excluded from the CCIP enrollment. See Appendix J and the CCIP Manual for more information.

Drug/Substance Abuse Testing: Consigli and all subcontractors (“Parties”) to the Consigli Contractor Controlled Insurance Program(CCIP) for the major construction project will participate in a Drug-Free Workplace Program, (the “Program”) which states that the use of illegal drugs or the abuse of alcohol, prescription or controlled substances on or off duty by persons working on/employed, or seeking employment, on this Consigli project, is inconsistent with a safe, healthy and productive work environment.

This Substance Abuse Program (“the Program”) is established by Consigli in response to the directive as recited above and supersedes any pre-existing ·programs.

Consigli project managers on the project covered by the CCIP will require that this Program be applied to all Contractor and Subcontractor-employed personnel working on the project site and to all applicants for such positions.

The intention of this Program is to establish the project as a drug and alcohol free workplace with due regard for the personal privacy interests of project employees. It is not the intention of Consigli project managers to intrude on off-duty activities of project employees away from the project site, unless those activities have a job-related impact. The circumstances permitting alcohol and drug testing on the project have been carefully defined. The Consigli project managers will retain oversight over the Program and will monitor test procedures for consistency and policy compliance.

The Parties acknowledge and agree on the importance of appropriate education, assistance, and treatment for all employees to combat the potential or actual influence of illegal/controlled drugs and alcohol. The Parties therefore encourage the utilization of the educational, assistance and

treatment programs which have been established by Unions and/or Contractors as an important component of the overall Substance Abuse Program on Project sites.

The Consigli Construction Substance Abuse Program establishes minimum standards of testing on a consistent, standardized basis for the safety, productivity and economy of all parties and personnel working on this project. · The Program will apply to all project workers, employees and applicants for employment on this covered project site and to all project Contractors at all tiers. The Construction Manager Consigli will regularly review with all Parties concerned the effective implementation and enforcement of the Program, and will require appropriate action by any and all Parties who are not fully committed to and involved in the application of the Program.

This Program shall be subordinate to the Department of Transportation Regulations or any other federal or state drug testing mandates which shall prevail and apply only to those classes of employees and applicants subject to the mandatory drug test regulations currently in effect, as amended or established in the future by the Federal Highway Administration, the U.S. Coast Guard, the Research and Special Programs Administrative of the Department of Transportation or any other federal or state agency with appropriate jurisdiction.

Drug testing will be conducted by:

OHS Total Care, A Division of OHS Training & Consulting

1340 Soldiers Field Road, Brighton MA 02135

Phone: (866)510-3002

**See the end of this Site Specific Safety and Health program for a copy of the actual Substance Abuse Testing program

Post Incident Review: Any incident that results in a recordable injury will require a post incident review. The worker who was injured along with their foreman/Safety Personnel/PM/Sup/etc. will need to fill out Appendix section R (Superintendent Report) and attend this meeting. At this meeting they will re-emphasize their commitment to safety, determine chronology of events, identify contributing factors, identify root cause, provide improvement plan to prevent reoccurrence and discuss disciplinary actions taken (if any). Findings from this meeting will be shared/disseminated with all contractors on site to prevent reoccurrence.

Identify the specific route in and out of the construction site (Traffic Management): Construction traffic will pull into and exit the site via Life Street. Access to the project will be limited to the turnstiles located on Life Street and Guest Street, with badges required for admittance. Access to the project will be limited to the turnstiles located on Life Street and Guest Street, with badges required for admittance.

Construction Air Quality: Construction activities will potentially generate fugitive dust, which could result in localized increase in airborne particulate levels. Fugitive emissions from construction activities will depend upon a multitude of factors such as ambient humidity, recent weather patterns, and phase of construction.

Dust Control

To mitigate dust emissions, Consigli and all site related contractors will be utilizing the following measures:

- Wetting agents will be used regularly to control and suppress dust that may come from exposed excavations, chipping, sawing, etc.

- Construction practices will be monitored to ensure that unnecessary transfers and mechanical disturbances of loose materials are minimized and that any emissions of dust are negligible.

- Street cleaning shall be provided on an as needed basis.

- OSHA Silica Guidelines will be followed for all dust creating activities.

- Compliance with the above-mentioned dust control measures will be monitored during daily safety walks performed by the site superintendent, as well as the safety manager. Conditions will be reported daily. Any required adjustments will be communicated to field personnel during daily foreman meetings.

Personnel Protective Equipment (PPE): Mandatory PPE must be worn at all times on site: ANSI approved Hard hats, ANSI approved Safety Glasses, ANSI approved Work Boots, High-Visibility Shirt or Vest, and CUT 3 Work Gloves, Cut 3 resistant sleeves for demo operations. ANSI Z87-rated safety glasses with rigid side- shields must worn over your eyes at all times. Standard prescription glasses are not sufficient protection. All personnel (including Consigli, vendors, visitors, workers, etc.) must wear Cut 3 Safety Gloves while on site. Proper gloves shall be worn for higher risk task-specific operations.

All workers on-site must wear ANSI-approved safety work boots, long pants (no shorts) and shirts with at least a four-inch sleeves (no tank tops). All personnel are required to use any necessary task- specific personal protective equipment (PPE), including face shields, hearing protection, respiratory protection, gloves, etc. All power tools must have the proper manufacturer-supplied guards installed at all times. Workers operating grinders, chop saws, abrasive cutoff saws, chain saws, tile saws, marble saws, brick/block saws, and similar tools must wear full face shields. All face shields are to be compatible with hard hats and worn with them. Personnel whose work requires the use of a respirator must be fit tested and their employer must have a written respiratory protection program. Workers using respirators must be trained in their use and maintenance and must not have facial hair where the respirators contact the face. These workers must also utilize engineering controls (i.e. wet methods, ventilation, smoke eater, etc.) to minimize the airborne contaminant or chemical exposure for co-workers, other trades and the public.

Cell Phone Use: Construction activities require constant focus on the task being performed. If concentration is lost and complacency sets in, this can lead to accidents. Private cell phone use shall be limited to break time. At no time will cell phone use be allowed when workers are performing tasks such as working with tools and/or around equipment/vehicular traffic or hazards. This will be reinforced during jobsite orientations. An inspection item has been added to the Predictive Solutions Construction Safety Audit to track compliance with the program.

Designated work hours (any work outside these hours must have prior CCC approval): All work shall take place during regular business hours of, Monday – Friday 7:00am to 3:30pm. Any work which may need to take place outside of these hours will need to be approved by the CCC Superintendent. Permits will be received by the city for early starts, late work, and any weekend work. All deliveries must be coordinated with the CCC superintendent with at least 48 hours’ notice.

Evacuation Plan (RACE, and Routes of Egress): Please refer to the Evacuation Plans attached. All workers shall attend the Project Safety Orientation. Consigli Construction’s Job Supervisor will conduct a safety orientation talk to each employee and subcontractor to site specific fire safety protocols.

Job Safety Analysis (JSA) A JSA shall be conducted for each identifiable feature of work to be performed. The JSA shall be submitted to Consigli superintendent/supervisor. The JSA shall be reviewed daily, signed by all workers including their supervisor, with all involved personnel performing that particular task.

Safety Stand-Down Policy

To ensure safe work performance for all Consigli Subcontractors. Production shall be suspended for repeated failure to comply with safety related issues or for a significant safety related incident or near miss. Requests of the Subcontractor at that point in time involves:

- Submission of incident investigation that determines “cause”

- Submission of safety plan moving forward to prevent similar occurrence

- Submission of training or re-training plan

- Upon repeated non-compliant related observations, or immediately following a serious incident or near miss, the Consigli Project Superintendent verbally issues to the subcontractor a cease and desist order for all production activities associated with the specific operation.

- A phone call shall then be made to the subcontractor’s owner/principal/project manager to establish a meeting time for the following day. Request during call that Subcontractor prepare:

- Submission of incident investigation that determines “cause”

- Submission of safety plan moving forward to prevent similar occurrence

- Submission of training or re-training plan

- Submission of a Certificate of Insurance for any incident that may have occurred with evidence of claim submission

- Conduct meeting with Subcontractor field supervision and project management to include:

- Review of aforementioned requirements

- Agreement between Consigli Project Superintendent and Subcontractor Project management as to when work can be restarted

- Creation of Meeting Minutes by Consigli Project Superintendent distributed to all

Safety Violations Management: The following progressive disciplinary action will be levied against employees and subcontractors who willfully ignore the safety standards and rules. CONSIGLI RESERVES THE RIGHT TO DISMISS ANY WORKER FOR ANY SAFETY VIOLATION AT ANY TIME DURING THE PROJECT. In addition, Consigli reserves the right to require retraining for any workers on site before they are allowed back on.

Disciplinary Action: Three Strike Program

First strike – Verbal Warning – given in Orientation

Second strike – Written Warning

Third strike – removal from the site.

Fire, smoking, alcohol, drugs and fall safety violation is immediate removal from the project no second chance!

FIRST OFFENSE: IMMEDIATE DISMISSAL!

- Theft

- Falsifying reports

- Willful, damage to company property

- Intoxication

- Drug policy violations

- Horseplay

- Fire/Smoking

- Falsifying reports

- Fighting

- Failure to report injuries

- Abusive or threatening language

- Possession of a weapon or firearm

- Verbal or sexual harassment of any member of the project or public

Fall Protection: The Consigli objective is to implement continuous fall hazard control whenever the potential exists for personnel falls from heights of six feet or greater. Employees on any walking or working surface which is 6 feet or more above a lower level must be protected by guard rails, safety nets, or a personal fall arrest system. Consigli’s preference for protection is based on a hierarchy of controls with elimination being the first consideration. The second and third considerations, being prevention and control respectively, are utilized if the fall hazard cannot be eliminated.

Fall hazard protection involves using personal fall arrest equipment to prevent the completion of a fall and to reduce the possibility of resulting injuries. Fall protection measures are taken when an employee’s exposure to a fall hazard cannot be eliminated or using fall prevention measures is not an option. Per Lendlease GMR’s, PFAS are not to be used as a primary means of fall protection. PFAS must be used in conjunction with properly installed safety nets. It is important to understand that post fall protection rescue must be planned in the event a fall takes place. This is necessary because of the response needed to prevent suspension trauma.

Recognized as the least desirable fall protection method that should only be used as a last resort, fall arrest systems include proper anchorage (rated to 5000 lbs. per person or 2x the dynamic rating of fall protection equipment) body support (harness) and connecting means (lanyards/lifelines) all interconnected and rigged to arrest a free fall. Personal fall arrest systems must be rigged in a manner that would prevent a worker from free-falling more than 6’ or making contact with any lower level.

This includes correct installation and proper use of:

-Rated anchor points

-Horizontal and Vertical Lifelines

-Self-retracting lanyards (yo-yos)

-Rope grabs, etc.

Selection of proper equipment is important and should be based on:

-The task being performed

-Requirement for worker mobility

-The number of employees requiring protection

-The distance of potential fall.

Typical Guardrails requirements include:

-Shall be constructed of at least 2×4 construction with the top rail able to withstand 200 lbs. of force.

-Top rail shall be at 60” plus or minus 3 inches

-Second rail shall be installed at 42 plus or minus 3 inches

-Mid-rail shall be ½ way at 21” between top rail and walking/working surface

-Toe boards shall be installed if an employee is exposed to falling objects. They shall be at least 31/2 inches high.

Floor openings larger than 2” must be protected by guardrails or covers. If guardrails are installed, they shall be constructed around all unprotected edges. If covers are used over holes, they must be capable of supporting 2X the anticipated loads and they must be secured to prevent accidental removal. In addition, they must be marked with words “HOLE” or “COVER”. Holes or floor openings larger than 30” x 30” shall be protected by standard guard rails. Slab openings for MEP penetrations sized 12’x12’ to 48”x48” have welded wire mesh (WWM) installed in them when the deck is poured. The opening is protected with a double plywood with chamfered edge with wood cleats and spray painted “HOLE”. If the WWM is removed prior to MEP installation, protection (double plywood with chamfered edge) must be mechanically fastened to the deck. Slab openings greater than 48” x48” are to be protected by vertical guardrails or cable system. Tie-off points will be identified prior to removal of any fall protection system. Controlled access zones will be established in order to keep other workers out of the area.

Fully protect openings to lift shafts with a secure full height system that prevents unauthorized entry and the risk of falls of people or materials. Shaft opening protection must remain in place until a safe working platform is provided or the lift doors are in place. Any perimeter/shaft fall protection that is removed must be replaced to its original condition prior to leaving the work area. If you observe a problem with any protection, please notify Consigli personnel. Do not remove any more protection than is necessary to perform the work at hand. Failure to properly replace protection will result in disciplinary action, including dismissal from this project.

Steel Erection: Steel erectors must submit to the Consigli Superintendent a site-specific steel erection plan written by a qualified person two weeks prior to commencing work. The plan shall contain minimally:

- Site Layout

- Sequence of erection

- Deliveries

- Staging & Storage

- Path of overhead loads

- Lift Plan/Crane Set-up

- Fall protection procedures (fall protection required at 6 feet for all operations)

- Post fall protection plan

- Training documentation

- Qualified and Competent person(s). Including Rigger/Signalperson

- Critical Lifts General Requirements:

- Sequence of erection

Consigli shall ensure that adequate access roads and a firm, properly graded, drained area, readily accessible to the work with adequate space for the safe storage of materials and the safe operation of the erector’s equipment.

It shall be assured that the concrete in Footings, Piers, Walls, and/or mortar in Masonry Piers and walls are in accordance with ASTM standard test method and has reached 75%

(Percent) of its intended minimum compression design strength and signed off by a qualified person. The Engineers test results shall be documented and sent to the steel erector prior to steel erection commencing utilizing the “Approval to Begin Steel Erection Form”

Prior to the erection of a column, Consigli shall provide written notification to the steel erector if there has been any repair, replacement or modification of the anchor rods (anchor bolts) of that column. This shall be documented by utilizing the “Approval to Begin Steel Erection Form” also and given to the steel erector prior erecting any columns on those anchor bolts.

Erection Requirements:

- Pre-shift visual inspection of the crane by a competent person must be done before the work begins on that shift and a copy of this inspection must be made available to Consigli in writing before the shift starts.

- All rigging shall be inspected before each shift by a qualified rigger and a written copy given to the Consigli Superintendent once per month. Defective rigging equipment shall be removed from service immediately. At a minimum the inspection shall meet 1926.251, which shall include but not limited to the following:

- Rigging equipment shall not be loaded in excess of its recommended safe working load

- Rigging equipment, when not in use, shall be removed from the immediate work area

- Special custom design grabs, hooks, clamps, or other lifting accessories shall be marked to indicate the safe working loads and shall be proof- tested prior to use

- Slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

- Welded alloy steel chain slings shall have permanently affixed durable identification stating size, grade, rated capacity, and sling manufacturer.

- Job or shop hooks and links, or makeshift fasteners, formed from bolts, rods, etc., or other such attachments, shall not be used.

- Natural and synthetic fiber rope slings shall be immediately removed from service if there are any signs of damage/wear.

- Each employee engaged in a steel erection activity that is on a walking/working surface 6 feet above a lower level shall be protected from falling by use of both a safety netting system and personnel fall protection system. Lendlease GMR’s do not allow PFAS to be used as a primary means of fall protection. When personal fall protection systems cannot be attached overhead, they must be of the appropriate type to account for 12’ free fall requirements as detailed in ANSI Z359.

- Protection from falling objects and the travel paths during the process of steel erection shall be reviewed daily to ensure that no loads are swung over and that no objects could fall on any persons. Air Horns will be used to warn personnel

that a load is being picked.

- It must be assured that proper fall protection is in place and reviewed daily by the competent person and that a written copy is given to Consigli with the daily report.

- Perimeter columns will have guardrails installed at 0”, 21”, 42”, and 60” above finish height of the structural slab to install 3/8 inch air craft grade cable or if using other devices, then it must meet the fall protection requirements (200 pounds in an outward and downward direction) or the anchoring point requirements (5000 pounds per person tying off to it). All wire rope shall be secured with at least three (3) Crosby Clips. Fire Rated debris netting will be installed on all floor.

- During decking operations metal decking shall be laid tightly and immediately secured upon placement. Personal fall arrest equipment used during decking operations shall be of the type that allows for the forces imposed on the lanyard by the leading edge. Stud welding will not occur directly above personnel on floors below. Floors below are to be inspected for flammables and combustibles prior to any stud welding.

- All floor openings shall be protected immediately. They shall be protected by constructing guardrails around them or by covering the hole. These types of protection must be in accordance with 29 CFR1926 Subpart M.

- Column anchorage shall be by minimum of 4 anchor bolts. Beam anchorage: minimum of 2 bolts wrench tight per connection prior to releasing crane hoist line.

Custody of Fall Protection:

This policy has been implemented to assure that, when the steel decking is complete on a given floor, a mechanism is in place to accept said floor so that other trades may safely commence work on that floor. This inspection shall be conducted by the Safety Manager in conjunction with the Superintendent and the steel erector’s representative. When turning over a floor, a copy of the Custody of Fall Protection Form will be given to the steel erector by the Consigli project team. There are several items that must be completed prior to allowing other trades to access and perform work on a floor. If all the items below are not completed, the floor is not to be turned over. The custody of fall protection form shall be made available to the decking crew to expedite fall protection installation and turn over procedure.

Required items prior to floor turnover:

- Overhead protection, being the next floor, must be complete in the area to be turned over.

- All openings on the floor to be turned over are to be decked over or otherwise covered (hole cover needs to be able to withstand twice the intended maximum load.) Large openings (i.e. elevator shafts, stair wells, etc.) must have proper guardrails, full height plywood protection, and toe boards in place.

- All pour stops on the perimeter of the building and all interior shafts must be in place. These act as the toe board (i.e. overhead protection) to the workers below these areas until the floor is poured toe boards are installed on the concrete deck.

- Access to the floor must be provided (ladders, stairs, etc.) On the 60 Guest St.

project, a combination of stair towers and permanent stairs will be used.

- All perimeter/interior (top & mid rail) cables must be tight and not deflect more than 3 inches. Turnbuckles must be installed at the end of each individual straight run. At no time shall any cable rail system (top & mid rail) be more than 12 feet without support.

- Guardrails installed at 0”, 21”, 42”, and 60” above finish height of the structural slab to install 3/8 inch air craft grade cable or if using other devices, then it must meet the fall protection requirements (200 pounds in an outward and downward direction) or the anchoring point requirements (5000 pounds per person tying off to it). All wire rope shall be secured with at least three (3) Crosby Clips.

- All top rails of the cable guardrail systems must be flagged for visibility with high visibility material at 6 foot intervals (Danger & Caution tape shall be avoided).

- Horizontal and vertical netting systems will be installed on each floor as the primary means of fall protection.

- No holes or gaps around the columns.

- Housekeeping must be completed by the ironworkers or their labor force.

Should any of the items above be deficient, the floor is to be rejected until it is corrected. If all items above are satisfactory, the form is to be completed and a copy given to the steel erector’s representative. A representative of the Safety Department is the only one to officially turn over a given floor. The Superintendent is also required to be present during the walk through.

It is permissible to turn the floor over in sections given that all the above items are 100% in the given area, there is means of access to this particular area, and there is a clear delineation between the area turned over and the area not turned over.

Excavations: Prior to the start of any work involving trenching or excavation operations the Sub- contractor Foreman involved in the trenching work must notify Consigli’s Superintendent. Consigli or the site work subcontractor will notify “Dig Safe” and local utilities prior to any excavation taking place.

The Dig Safe reference number to be submitted to Consigli prior to work activities beginning. The Subcontractors management or supervision shall designate a “competent person” (one who has knowledge of the excavation standard, who can identify hazardous conditions, and has authority to stop work at any time the excavation does not meet all safety related requirements) to complete the Consigli Excavation Checklist prior to starting work.

**State of Massachusetts Requires permits in reference to “Jackie’s Law”. A trench permit must be obtained from the municipality or town work is taking place in and submitted to Consigli prior to starting work. If the city or town does not have permitting in place, then the excavator still needs to follow 520 CMR 14.00. “Jackie’s Law” requires and attendant, barrier, or cover for excavation greater than 3 feet in depth.

It is the responsibility of the Superintendent to assure that all excavations are conducted in accordance 29 CFR 1926. Close monitoring of all trenching/excavation operations by the Superintendent shall involve:

- A pre-excavation safety meeting will be held with the Safety Department, Superintendent and Subcontractor Foreman, with Subcontractor Foreman providing Excavation Checklist prior to any trenching operations taking place.

- Any contractor found excavating a trench improperly shall be stopped immediately and not allowed to continue until proper corrective action has been taken to abate the hazard.

- The contractor conducting the excavation operation will designate the person competent to perform the work. The competent person will demonstrate to the Superintendent his knowledge of soil conditions and the Contractor’s ability to conduct a safe operation. The competent person shall be on site while excavation work is taking place.

- As previously stated, the Excavation Checklist shall be completed by the Site Contractor’s Competent Person, and submitted to Consigli’s Superintendent prior to any employee entering an excavation 5 feet or greater in depth.

- In excavations greater than 4 feet in depth and where oxygen deficiency (atmosphere containing less than 19.5 percent oxygen) or Hazardous Atmosphere exists or could reasonably be expected to exist, the atmosphere shall be tested and documented by the competent person on site before employees are allowed to enter.

- Excavations 5 feet or greater in depth shall be protected by sloping or shoring and be inspected using the excavation checklist. The Competent Person shall determine the soil classification prior to any excavating taking place and complete all required inspections. Tabulated Data for trench boxes are to be submitted and reviewed prior to use.

- Access shall be provided in excavations 4 feet or deeper. Trench access shall be located such that no employee has to travel more than 25 feet to the access

point. Extension ladders must be fiberglass and have a minimum rating of 300lbs (Type 1A).

- During the excavating process, excavated material shall not be placed closer than 2 feet from the edge of the trench/excavation. Excavations will be cordoned off as a means of creating a controlled access zone for workers.

- Excavations left open overnight shall be inspected by the competent person prior to the start of the next day’s activities to ensure the continued stability of the walls of the excavation.

- Notify “Dig Safe” or other utility locating organizations to help eliminate potential hazards to workers and unnecessary shutdowns that could be created when electric lines, gas lines, pipe lines, sewers and so forth are exposed during trenching and excavation operations. Hand digging will occur within 3 feet of underground utilities.

- Assure that adequate sloping and benching configurations coincide with the type of soil in which the excavation is taking place.

- Verify compliance with Engineer’s designed earth support systems, and assure that manufacturer’s tabulated data for all utilized trench boxes, is available in the project office. The manufacturer’s tabulated data limitations must be highlighted and complied with while the trench box is in use.

- If manufacturer’s tabulated data is unavailable, a registered professional engineer must provide stamped drawings for the protective system to be used.

- A copy of the Federal Register 29, C.F.R., Part 1926.650 to 1926.652 and all related appendices must be kept on the project at all times.

- Excavations greater than 6 feet in depth will require perimeter fall protection to be installed, i.e. railing system/Garlock system in accordance with OSHA 1926.502.

Concrete Construction:

- Gloves, rubber boots, face protection and hardhats will be worn when pumping, placing, or spreading out concrete.

- Cement burns are a potential hazard, especially during the warm summer months. Best and easiest first aid treatment is water, which must be available to wash concrete off the skin before it can burn. Vinegar or a commercial neutralizer can be used to counter act the burning effect. Report all cement burns to the foreman/supervisor at once.

- Concrete weighs 150# per cf. Maintain stable footing and good balance to avoid strains and sprains from over-lifting and shoveling.

- All protruding reinforcing steel, onto which an employee could fall, must be guarded or capped, as appropriate.

- Reinforcing steel for walls, piers, columns and similar vertical structures shall be adequately supported to prevent overturning and to prevent collapse.

- No employee shall be permitted to place or tie reinforcing steel more than six feet above an adjacent working surface without the use of conventional fall protection devices (harness and lanyard, guardrails, or safety net.)

- No employee shall ride in concrete buckets.

- No employee shall be permitted to work under concrete buckets while buckets are being elevated or lowered into position. Buckets with hydraulic or pneumatic gates will also be equipped with positive safety latches to prevent premature or accidental dumping.

- All formwork shall be designed, fabricated, erected, braced and maintained so that it will be capable of supporting, without failure, all vertical and lateral loads that may reasonably be anticipated.

- All shoring equipment shall be inspected prior to erection to determine that the equipment meets the requirements specified in the formwork drawings. Defective equipment shall be removed from service before use.

- Power troweling machines must be equipped with trigger switches that automatically turn off the equipment when pressure on the switch is released.

- Concrete hoses will be inspected prior to use. Pins shall be placed on all hose clamps.

- Always provide access across rebar prior to placement. Good access will prevent injuries caused by slips, trips and falls.

Work on Ladders: Use of ladders to access work is discouraged. Wherever possible, an alternate means of access is to be employed such as scissor lifts or elevated work platforms with guard rails. If ladders are to be used, workers need to use the right size and type ladder for the work they are performing. Ladders must be Type 1A minimum (300lb rating) and must be fiberglass. Platform ladders are the only acceptable ladder to be used as a work surface on this project. Platform ladders are not to be leaned in the closed position. Extension ladders should only be used for access and egress.

Roof Work: Before any work is to begin on the roof it must be determined what sections of the roof will be worked a method of fall protection will be implemented. On this project, guardrails will be the only acceptable means of fall protection. Holes greater than 2” will be covered with acceptable material (3/4 plywood ½ steel) which will be secured and marked hole (cover must be able to withstand two times the intended load). Covers will stay in place until the hole/penetration has been filled with duct or Pipe riser which extends above the deck. The roof will be made water tight by the end of each shift.

Scaffolds: Each employee on scaffolding more than 6 feet (3.1 m) above a lower level shall be protected from falling to that lower level. This includes required fall protection for all erection and dismantling. all scaffolding be under the direction of a “Competent Person” competent in the erection of scaffolding. A copy of the designated “Competent Persons” resume/certifications shall be submitted by the erection company to the Consigli Superintendent prior to installation.

When a subcontractor is responsible for the sole use, erection, and dismantling of scaffolding, Consigli will verify that the subcontractor is managing the inspection and tagging system. Consigli will provide the tags, orient the subcontractor on the process, assure that daily inspections are being conducted, and that the tags are being initialed. Consigli is required to assure that all scaffold erection and scaffold use is under the direction of a competent person. There should never be a crew working on scaffolding without the oversight of a competent person. In multi-use staging it will ultimately fall back onto the controlling contractor, Consigli, to assure that the scaffolding is being managed and inspected. A-Frame Scaffolds are prohibited.

Requirements for Supported Scaffolds:

- Scaffolds shall be designed by a qualified person and shall be constructed and loaded in accordance with that design.

- Each scaffold and scaffold component shall be capable of supporting, without failure, its own weight and at least 4 times the maximum intended load applied or transmitted to it.

- Each platform on all working levels of scaffolds shall be fully planked or decked with a space of no more than 1 inch between the front uprights and the guardrail supports.

- The scaffolds front edge shall not be more than 14 inches (36 cm) from the face of the work, unless guardrail systems are erected along the front edge and/or personal fall arrest systems are used.

5. The maximum distance that plastering or lathing operation shall be conducted

from the face of work is 18 inches (46cm).

- The maximum distance allowed on outrigger scaffold to the face of work/building is 3 inches.

- Each end of a plank shall extend at least 6 inches (15cm) over the support unless cleated or restrained.

- Planks 10 feet or less shall not extend more than 12 inches (30cm), if the plank is over 10 feet it shall not extend 18 inches (46 cm) over the support unless the planks is or designed to support employees and their materials without tipping.

- When planks are overlapped to create a longer planks or to turn a corner this shall occur over supports and shall overlap by at least 12 inches (30cm).

- Planks shall not be covered with a coating of paint or stains that may obscure the top or bottom wood surfaces.

- Planks shall not deflect more than 1/60 of the span when loaded.

- Scaffold components manufactured by different manufacturers shall not be intermixed or modified unless the components fit together without force and the scaffold’s structural integrity is maintained and a competent person determines the resulting scaffold is structurally sound.

- Supported scaffolds with a height to base width ratio of more than four to one (4:1) shall be restrained from tipping by guying, tying, bracing, or equivalent means. These types of support shall be installed according to the scaffold manufacturer’s recommendations or at the closest horizontal member to the 4:1 height.

- This shall be repeated vertically at locations of horizontal members every 20 feet(6.1 m) or less thereafter for scaffolds 3 feet (0.91 m) wide or less, and every 26 feet (7.9m) or less thereafter for scaffolds greater than 3 feet (0.91 m) wide.

- Supported scaffold poles, legs, posts, frames, and uprights shall bear on base plates and mudsills or other adequate, firm foundation.

- Footings shall be level, sound, rigid, and capable of supporting the loaded scaffold without settling or displacement.

- Unstable objects shall not be used to support scaffolds, platform units or used as working platforms.

- Supported scaffold poles, legs, posts, frames, and uprights shall be plumb and braced to prevent swaying and displacement.

- When scaffold platforms are more than 2 feet (0.6 m) above or below a point of access, portable ladders, hook-on ladders, attachable ladders, stair towers (scaffold stairways/towers), stairway-type ladders (such as ladder stands), ramps, walkways, integral prefabricated scaffold access, or direct access from another scaffold, structure, personnel hoist, or similar surface shall be used.

- Cross-braces shall not be used as a means of access.

- Employees shall be prohibited from working on scaffolds covered with snow, ice, or other slippery material except as necessary for removal of such materials.

- Ladders or makeshift devices, such as but not limited to boxes and barrels, shall not be used on top of scaffold platforms to increase the working level height of

employees.

- Requirements for Mobile Scaffolds:

- All mobile scaffolds will be inspected prior to use.

- Use of mobile scaffolding will require that all wheels are locked prior to workers accessing the scaffolding.

- All mobile scaffolds shall have guard rails installed once the working deck of the scaffold reaches 4’ in height, or manufacturer’s specifications, whichever is less. In the event guard rails will not fit, a personal fall arrest system must be utilized. The use of a PFAS must be approved by the site safety department prior to use.

- Any time a mobile scaffold reaches twice the minimum base dimension (less if required by the manufacturer), scaffolds shall be equipped with outriggers, or shall be otherwise restrained against movement.

Aerial Lifts/Scissor lifts: Area and ground conditions in the intended work area will be inspected for overhead power lines underground structures/sink holes, covers or any other unsafe condition which cause an unsafe incident. Aerial lift platforms/scissor lifts will be inspected daily before each shift by a competent person designated by each individual contractor who will be using it, which will be documented on Inspection tags for each individual piece which will be filed in the site office. All contractors who will be performing work from an aerial lift will show documented proof of training for all workers who will be using the lift. Steel plates or equipment mats will be placed on the ground above any utility/ steam tunnel/underground vault if there will be Aerial lifts operating on them.

Operation: Materials placed in basket shall not extend beyond the outer edges of the basket. Do not stand on the rails, always keep your feet on the platform. Planks, ladders, or other devices shall not be used to raise the height of the platform. Do not use the aerial lift to access any structure. Personnel may exit with prior approval from the superintendent when all other means of access are impractical or create a greater hazard, as long as continual tie off is maintained. The basket must be at its lowest possible elevation when moving the machine. Operator shall read and obey all warning placards and become familiar with owner’s manual. Spill kits shall be brought to site with all aerial and scissor lifts. Workers will be tied off at all times when using aerial and scissor lifts.

Haz Com/Global Harmonization: All Contractors on site are required to submit a copy of their HAZCOM Program, with all applicable SDS’s, and a company safety manual to Consigli. All HAZCOM programs will be kept in the field trailer for everyone’s convenience. Any time a Contractor brings a new product onto this site they shall assure that the product has a valid SDS, and a copy of that SDS is placed in with their respective SDS Log. Any questions regarding products should be first addressed with the affected employee’s supervisor. However, no employee will be denied the opportunity to look up an SDS for a product he is required to use or any product another contractor is using or is about to use.

Fire Protection: The Consigli hot work permit program will be implemented for any hot work that is required. This will be coordinated through Lendlease, Consigli, and the Boston Fire Department. Cutting and welding operations shall include the following: Floors should be swept free of combustibles within 35 feet of the work area and any flammable liquids should be removed from the area. Wet down the immediate area, where applicable. A fire watch, when necessary, shall be available while work is being performed, during all breaks, and at least 1 hour after operation is shut down. Fire watches will remain in place for 2 hours after any hot work on the roof. Fire extinguishers will be required. The subcontractor shall provide floor sweeping, moisture application, fire watch duties and the provision of fire extinguishers. Prior to any burning taking place the Subcontractor shall request a “hot work permit” from the Consigli Superintendent. Any hot work will stop one hour before the regular end of the day work stoppage. Flammables will not be stored inside the building or left overnight on the scaffold or in the building. All combustible or flammable materials will be stored in an appropriately rated lockable cabinet located no closer than 15 feet from the nearest structure. Fire extinguishers will be provided for every 3000 square feet. They will be installed on job made stands and conspicuously located throughout. They will be part of the daily inspection with the extinguisher log completed monthly. Storage of any acetylene cylinders will be done in a secure and upright area, with good ventilation and under permit from the Boston Fire Department. This will be a strict no smoking project. All penetrations leading outside of the construction area will be fire stopped using approved fire rated material prior to the end of each shift. Fuel storage will be located along Guest Street. ALL workers will comply with the 241 plan and AFD/NFPA Hot Work Training Requirements.

Temporary heating devices should not be installed or used by anyone on the job until authorized by the Project Superintendent and cleared with the local Fire Department. Electric space heaters shall not be used. When polyethylene sheeting, tarpaulins, or canvas coverings are used on the project, they must be U.L. listed fire resistant material with a flame spread rating of 15 or less should be used and at least a 10-foot clearance should be maintained. These materials should be securely fastened.

NFPA 241 Plan: A written fire prevention plan has been prepared for this site and is filed in the Consigli field office. In the program, Nick Nowak, has been designated as the Fire Protection Program Manager.

Electrical Safety: All electrical equipment will be treated as energized, unless a zero-energy condition is confirmed by a qualified person. Any electrical equipment, panels, junction boxes that are energized will be posted. Live panels shall not be left unattended unless protective panel covers have been put back in place protecting workers from coming into contact with live parts. Clearance distances for anyone working in the vicinity of live electrical shall be established in accordance with NFPA 70 E. It shall be Consigli Policy that no distance is safe. No live electrical shall be exposed. Any energized equipment, or electrical switch- gear will be equipped with and fall under the OSHA lock out/tag out standard. (1926.417). A Lockout Tagout program shall be developed, if needed, utilizing the program established by the electrical contractor to assure that all employees are trained in the same manner following the same policies. Any Vehicle or mechanical equipment capable of having parts of its structure elevated near energized overhead lines shall be operated so that a clearance of 10 ft. is maintained, 20 ft. for crane operations. If the voltage is higher than 50KV the clearance shall be increased 4 inches for every 10KV of that voltage. If alternative measures are requested the Consigli Safety Department shall be contacted.

All electrical tools, cords and equipment must be in good working order. To that end, all electrical tools and components must be visually checked on a daily basis. Any tools with damaged cords or damaged cords must be taken out service… All cords must be equipped with a ground pin, flat three wire cords are not allowed. SJO and SJT or other similarly rated cords only shall be used. The electrical subcontractor will be responsible for all temp power and any temp lighting that may be needed. They will coordinate all lock out tag out procedures. All temporary power for the project will be installed on protected and dedicated circuits with 100% GFCI protection. All splices in temporary electric wiring shall be protected, at a minimum, with electrical tape. The protection must extend to the original wire sheathing/insulation, this shall include wire nuts. All temporary lighting must be suspended by non-conductive material. It may not be suspended from any life safety systems (sprinklers, fire alarm, etc.) All panels shall have sufficient clearance so as to allow access by qualified persons. Sufficient

clearance is a minimum of 3’. GFCI will be tested by the electrical subcontractor weekly to assure proper function with a log book filed with CCC monthly. No live electrical work will be conducted.

Lock-Out/Tag-Out: There are two types of energy isolating devices: those capable of being locked (lock-out) and those that cannot be locked out (tag-out). Lockout is a more reliable method of de-energizing equipment than tag-out and is the preferred method. When, however, the energy-isolating device cannot be locked out, subcontractors can, after consultation with Consigli, adopt the use of a managed tag-out system. Each individual lock will only have 1 keyholder.

Responsibilities:

- Electrical/Mechanical/Equipment Subcontractors: Responsible for planning deliberate energy control program to ensure that machines and equipment are isolated and inoperative before any employees perform servicing or maintenance. They shall also be responsible for Periodic inspections to assure that energy

control procedures (locks and tags) continue to be implemented properly and that employees are familiar with their responsibilities under these procedures.

- Consigli Superintendent to be included in all electrical coordination issues.

- Subcontractor Supervisor/Foreman: Responsible for training employees working with the equipment, type(s) of energy, and hazard(s) specific to the particular jobsite. In addition, the Supervisor/Foreman will be responsible for obtaining the appropriate lock-out-tag- out devices.

- Authorized Employee: Responsible for implementing the energy control procedures, installing locks and tags and performing the service or installation. Each AE shall have his/her name on locks/tags accordingly.

Shutdowns: Procedures for shutting down specific pieces of equipment (pumps, boilers, air handing equipment, etc.) are only to be done by qualified individuals. Installation, start-up, and servicing are outlined in the Installation and Operation and Maintenance Manuals that accompany each piece of equipment at shipment and should be followed. Additionally, work that involves the transmission and distribution systems for gas, steam, water or petroleum products need to be part of all discussions regarding lock-out/ tag-out.

Generally, the procedure for applying energy controls by contractors includes the following elements and actions that need to be planned and implemented in sequence:

- Preparation for shut down.

- Shut down of energy to any machine or equipment.

- Application of the lockout or tag out device by responsible contractors

- Assuring all stored or residual energy is released safely

- Verify the location and de-energization of the machine or equipment.

- Temporary lighting provided for workers in area of shutdown

Removal of Locks and Tags: Before lock-out or tag-out devices are removed, the Authorized Employee(s) shall take the following actions or observe the following procedures:

- Inspect the work area to ensure that non-essential items have been removed and that machine or equipment components are intact and capable of operating properly;

- Check the area around the machine or equipment to ensure that all employees have been safely positioned or removed;

- Notify all Affected Employees immediately before removing locks or tags and before starting equipment or machines

- Make sure that locks or tags are removed ONLY by those employees who attached them.

- Follow the manufacturer’s start-up procedures outlined in the Installation Manuals and Operations and Maintenance Manuals which accompany each piece of equipment at shipment.

Hand and Power Tools:

- All hand and power tool related injuries will be reported at once to the Consigli Superintendent so that proper medical treatment can be obtained, and damaged tools taken out of service. Foremen will report each crew injury by completion of shift to project office.

- No machines, tools, etc. will be operated until guards and any auxiliary handles are in place.

- Machines, hand tools, pneumatic tools, etc. will be inspected prior to use and if found defective, it must be reported, and the defective tool taken out of service immediately.

- When in doubt on operating procedures, insist upon being instructed on operation and how to utilize all tools in a safe manner.

- Familiarize yourself with the location, and type of all fire extinguishers on the project.

- Equipment will not be left unattended while in operation or motion.

- Portable electric equipment will be unplugged when not in use.

- Compressed air tools shall have air shut off when not in use. Air hoses shall not be crimped or kinked for the purpose of changing tools or equipment. Hoses shall be inspected for breaks, and all clamp connectors should be safety wired or whip-checks installed. All compressors with hoses equal to or greater than 1/2″ in diameter shall be equipped with check and or excess flow valves (pressure reduction valve). Every air receiver shall be equipped with an indicating pressure gauge and one or more spring loaded valve. Safety valves shall be tested and the receiver drained frequently.

- Compressed air is not to be used for cleaning unless the pressure is under 30 psi.

- When Compressed air is used for abrasive blasting, the blast nozzle shall be bonded and grounded to prevent the build up of static charges. The blast cleaning nozzles shall be equipped with an operating valve which must be held open manually (constant pressure switch).

- Loose or torn clothing will not be worn around moving equipment. Minimum clothing requirements on Consigli sites are long pants, a shirt with shoulders covered, and good work shoes.

- Do not use hands for holding work while drilling.

- Report all hazardous conditions to your immediate supervisor at once.

- Gasoline shall not be used for hand washing. Only UL listed safety cans with vents and flash back screens will be used for gasoline storage.

- All power tools used by Consigli employees shall have Automatic Torque Control (ATC) mechanisms for tools that can be equipped with ATC.

- All extension cords must be 12 gauge or greater.

- All cords must be provided with GFCI protection.

Powder Actuated Tools:

The following procedure shall be followed for the use of Powder-Actuated tools:

- Only qualified operators shall operate explosive-actuated tools. A qualified operator is one who has been trained by an authorized instructor and provided with an authorized instructor’s card by the tool manufacturer or by an authorized representative of the tool manufacturer.

- Possesses a qualified operator’s card supplied by the manufacturer and issued and signed by both the instructor and operator

- Each tool shall be provided with the following:

- A lockable container

- Operator’s instruction and service manual

- Powder load and fastener charts

- Tool inspection record

- Service tools and accessories

- Tool maintenance and inspection

- Daily inspection, cleaning and testing shall be performed as recommended by the manufacturer.

- Tool Security

- Powder actuated tools and the charges shall be secured at all times to prevent unauthorized possession or use.

- Powder actuated tools shall not be loaded until just prior to the intended firing time; neither loaded nor empty tools are to be pointed at anyone; hands are to be kept clear of the barrel end.

- All spent and any unspent charges shall be placed in containers kept for that purpose and removed from the job-site on a daily basis. At no time will charges be allowed to remain unattended.

- When not being used, powder-actuated tools and charges will be kept under lock and key in a secure container such as a Gang Box. Only a sufficient number of charges shall be available in the work area to accomplish the planned work for any given day.

- Each Subcontractor required to use powder-actuated tools shall advise Consigli’s Superintendent where they are storing their powder-actuated tools and charges. The powder actuated charge quantity is governed by the authority having jurisdiction.

- Each storage area shall have this procedure posted in a conspicuous location and all operators on powder-actuated tools will be trained in this procedure prior to start of their work.

Material Handling: Before manual materials handling is conducted a hazard analysis shall be conducted with the following considerations made:

- Lifting any material over 10 feet in length or 80 lbs. shall only be done with 2 workers.

- Evaluate to assure that it cannot be done mechanically (to be enforced by Consigli Foremen) first before attempting to manually lift.

- Fork truck availability

- Use of pallet jacks, dollies or other lift assisted equipment

- Proper lifting technique shall always be practiced (training for Consigli personnel will be conducted at the beginning every project):

Bring load as close to the center of your body as possible

- Bend at the knees and utilize legs, not back, for actual physical lift.

- Keep spine at 45 degrees and straight from hips to shoulder.

- Ideally lift from waist height to shoulder height, avoid lifting from below waist or placing above shoulders.

- Report all strain/sprain related injuries immediately as well as any hazardous conditions that could lead to musculoskeletal related injuries.

- All materials must be stored on wheeled carts, racks, or bins.

Foremen and superintendents shall periodically evaluate work areas and employee work technique to assess the potential for and prevention of strain related musculoskeletal related injuries.

Crane Safety Policy: There will be two tower cranes erected on this project. Full engineering and swing calculations have been conducted and are available in field office. Mobile crane use on the project is also anticipated. The location and set up will be reviewed with crane owner/operator prior to set up and pick. Crane work plans must be submitted to the CCC safety Department prior to crane mobilization on-site.

This work plan must also include the FAA criteria letter of determination with regards to crane proximity to flight lines. There is a requirement to assure that certified riggers, signalmen, and crane assemblymen are utilized. All picks are to be done by a licensed operator. As previously mentioned, a detailed pick plan will be required to assure that no picks are critical in nature.

Critical picks are defined as those involving 2 cranes lifting simultaneously, a pick that is over 75% of capacity, a pick that involves the lifting of a man basket, or any other lift that is deemed to involve special conditions. Location and set up will be reviewed with crane operator prior to set up and pick.

Inspections:

Hydraulic cranes and truck mounted boom cranes: All hydraulic cranes and truck mounted boom crane shall have had a thorough inspection, in the last year prior to arrival at the jobsite, by a competent third-party inspector. That inspection record, with identification of inspector stated clearly on it, shall be provided to the Consigli Project Superintendent prior to the crane operating on site.

After confirmation that the machine has been inspected and certified within the last year by a competent third party, the following procedures shall be followed:

- Superintendent and Consigli Safety Manager meet with the foreman, operator, and oiler, if assigned, to assure a thorough completion and implementation of a daily and monthly inspection checklist assigned to that machine.

- Establish positively, the weight of each load before handling. Check machine stability and maximum operating radius to assure all loads are within 75% as established by the cranes load chart. Any loads over 75% are considered critical. Any pick over 90% capacity will require both the Consigli Safety Director’s and Lendlease approval.

- Observe hydraulic crane booms, to include all telescoping sections, and the

hoisting system hydraulic cylinders, for any damage, or leaks. Assure that no booms have any welded add-ons. If any welded add-ons to the boom are noted, assure that Manufacturer approvals are on file for that particular machine.

- Coordinate date for an independent Third Party Inspection service for crane if any questions arise concerning crane maintenance or set-up.

- Assure operator is qualified to operate the crane which they are operating.

Lattice Boom, Tower Cranes, and Mobile Cranes erected on-site:

To assure that all cranes utilized on Consigli projects are in safe operating condition, a third-party independent inspection shall be conducted on site on all subcontractor’s Lattice Boom, Tower Cranes, and Mobile Cranes erected on-site, during set up and prior to operation.

Crane Operation:

- Only the following qualified personnel shall operate cranes:

- Designated operators complying with State or City Laws

- Maintenance and test personnel when they have the specific training and hands on work experience to operate, test or maintain the type of crane that they are servicing

- Qualified Crane Inspectors

- Maintain continuous contact, visual or vocal, (with a radio that has a dedicated channel or hard wired communication system) between the crane operator and one qualified signalman. If for any reason contact is lost, the crane operator shall stop all operations and not resume any crane function until full contact is restored.

- The crane must have sufficient capacity and proper type (crawler, rough terrain, truck cranes, mechanical or hydraulic) to fulfill all requirements of the work without endangering personnel or equipment.

- Outriggers on all truck cranes shall be fully extended and set for all lifts. Lifts shall not be attempted with outriggers partially extended and set. Outrigger floats shall be on proper dunnage (solid with no gaps) that is 3 times the area of the float or per manufacturer’s specifications. No pick and carry lifts are to be made with truck cranes.

- Rough terrain cranes operated in stationary position shall have outriggers fully extended and set before any lift is made.

- The operator must not attempt any lift for which he/she feels conditions are inadequate. The crane operator has the authority to stop and refuse any loads until a qualified person has determined that the pick can be made safely.

- Only qualified crane personnel shall direct the changing or disassembly of crane booms. Consideration should be given to having the manufacturer’s representative present.

- The operator shall observe the following precautions when leaving the control station of a machine:

- Disengage the master clutch.

- Lower bucket or crane load to the ground.

- Set safety pawls on all drums where these are operated manually.

- Set the swing brake and travel brakes to prevent machine movement when lifts unattended for short periods and operator remains in immediate area.

- When crane is left unattended for extended periods of time or the operator leaves the immediate area, all brakes and locks shall be engaged.

- Cranes shall be operated smoothly, avoiding sudden stops and starts.

- The hoist line must be vertical at all times.

- At no time shall personnel be positioned beneath suspended loads, other than those engaged in rigging or disconnecting of a load.

- No one is permitted to ride the hook or the load.

- The boom hoist drum pawl should be engaged at all times except when lowering the boom.

- Do not get on or off a machine when it is in motion. No adjustment, repair, or lubrication is permitted on moving machinery unless required by the manufacturers.

- Work within 20 feet of electric lines is prohibited. A Job Safety Analysis shall be written with all parties (to include local power company) involved in any work within the defined 20 foot work zone. Lines must be insulated within the defined 20 foot work zone.

- All loads require a tag line.

- No tool boxes, oil cans, choker racks, water coolers or similar additions may be placed in the radius of the swing of the counterweight where a person could conceivably be struck.

- Swing radius of the counterweight must be barricaded with rope or chain. Caution or danger tape is not a sufficient barricade.

- Lifts associated with steel erection and concrete bucket handlings are the only crane operations where free-fall can be used.

- The manufacturers operations manual and load charts associated with the machine shall be in the cab of the crane at all times.

- Manufacturer’s instructions and prohibitions must be followed at all times during the assembly and/or disassembly of the crane.

- All manufacturer procedures applicable to the operational functions of equipment, including its use with attachments, must be complied with at all times.

- All cranes shall be equipped with an anti two-blocking device which will cease all operations of the crane in the event that operation will result in the crane becoming two-blocked. Cranes set up for duty cycle operation, for example pile driving, are exempt from using an anti-two block device.

- An ABC fire extinguisher, load chart, and operator’s manual, inspection log are required to be in the cab at all times.

- No crane shall be allowed to operate if wind speeds exceed manufacturer’s specifications or federal, state, or local regulations.

All safety devices must be on equipment and must be in proper working order prior to operation. If any of the devices are inoperable, the equipment must be taken out of service until such components are repaired or replaced.

Forklifts, Lulls, Bobcats and All Powered Industrial Vehicles

All Consigli personnel and Subcontractors who intend to use this equipment shall comply with 520 CMR 6.00 and follow the requirements of Federal OSHA Regulation, in particular 29 CFR 1926 and 1910.

All workers must be trained and certified by a qualified instructor in the specific piece of equipment they will operate. Training shall involve classroom instruction/testing and practical operation instruction/testing, with said training conforming to the requirements of the manufacturer. Retraining is to be conducted every 3 years or at any time the Consigli Superintendent recognizes inadequacies in operation or if an incident occurs. Training will include understanding load capacities of individual machines, distances at which loads can be picked and placed, re-fueling requirements, operation of machine on slopes and ramps, visibility requirements when traveling forward or backing, and balancing and counter balancing consistent with manufacturers requirements.

- Only authorized (training and proficiency testing) Consigli employees shall be allowed to operate any mobile equipment owned by the company. All workers need to have a State License with a class level of 1C or greater in MA.

- The operator’s manual and fire extinguisher must be with the equipment at all times.

- Load chart must be posted in cab at all times. At no time shall equipment be loaded beyond its rated capacity.

- At no time are any loads or materials to be suspended from the forks or any part of the cradle assembly, traffic carriage, or boom. All loads shall be secured for safe transport. Only manufacturer approved devices which were specifically designed for this task will be allowed. Additionally, the operator shall not attempt to use the machine in any manner or for any purpose other than that for which it was designed.

- If the machine is being used inside a building then air quality needs to be reviewed. This includes scrubbers being installed on the exhaust of the equipment to reduce the quantity of gases being released from the equipment. The scrubber, air quality, and machine must be reviewed and monitored on a regular basis.

- All equipment is to be inspected before each shift in compliance with

manufacturer’s recommendations. Copy of the inspections performed will be kept on site.

- The inspection shall be documented using the Powered Industrial Vehicle Inspection Form or approved equivalent.

- All equipment shall be fitted with working back-up alarms. If background noise renders back-up alarm inaudible, then an assigned competent person shall be employed to oversee backing of equipment.

- Seatbelts shall be worn at all times by all equipment operators. Unless equipped, passengers shall not ride on equipment.

- Eye protection shall be mandatory for anyone operating equipment in an unenclosed cab.

- Fueling of any and all equipment shall be done only after the engine has been shut off. No smoking signs shall be posted and fire extinguishers mounted and available

in the area where refueling is to be done. A spill kit shall be readily available and appropriately located near refueling areas.

- Any time equipment or lifts are operating on site, each subcontractor is to have a spill kit available for immediate use in the event of a release of restricted or non- restricted material. Workers are to follow the guidelines set forth in the Consigli Spill Containment Program, at a minimum. Subcontractors may follow their own plan provided all of the items in Consigli’s Spill Containment Plan are met.

Confined Space:

The purpose of Consigli’s Confined Space Program, as outlined below, is to assure that entrants are protected from the hazards associated with confined spaces.

Definitions:

A confined space is defined as any space that is: 1) Large enough and so configured that an employee can bodily enter and perform assigned work; 2) has limited or restricted means for entry and exit, and 3) is not designated for continuous employee occupancy.

A permit required confined space is defined as having one or more of the following characteristics:

1)Contains or has the potential to contain a hazardous atmosphere (either by the accumulation of hazardous gasses, mists, fumes, vapors, or dusts, or the possibility of an oxygen deficiency);

2) has and internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls;

3) contains a material that has potential for engulfing an entrant or;

4) contains any other recognized serious physical safety or health hazards.

A Confined Space Entry Permit is used when a physical or atmospheric hazard cannot be controlled or eliminated.

A Confined Space Alternate Entry Certificate is used when all physical and atmospheric hazards have been eliminated or controlled.

Examples of confined spaces include: vaults, tunnels, manhole, sewers, any tank, tank cars, tank trucks and certain parts of structures such as bins, silos and hoppers.

Responsibilities