Project # 2859 – Orsted O&M Hub

22 Research Way E. Setauket, NY 11733

Emergency Response Plan

ALL EMERGENCIES SHOULD BE REPORTED BY CALLING 9-1-1

PURPOSE: The purpose of this Site-Specific Safety and Health Program is to illustrate Consigli’s approach to identifying project specific hazards and controls and how said risk is managed through a comprehensive Safety and Health Program.

S.A.F.E.: Staying Accident Free Every Day is the Safety Mission that forms the very foundation of the Consigli Safety Culture. The S.A.F.E. mission, which is supported by technology, (Predictive Solutions internal auditing instrument which identifies and defines leading indicator related information); Leadership (Empowering our team members to assure safe projects); Humanization (Protect the ones you love by protecting yourself); Training (Integrating sub-contractors into the Consigli Safety Culture); is the driving force behind Consigli’ s drive to our vision – ZERO. ZERO is the philosophy that all accidents are preventable, and that no accident is acceptable. The S.A.F.E. mission is the guiding force to achieving the Consigli Safety Vision which is ZERO.

SITE INFORMATION

This Emergency Response Plan (E.R.P.) is specifically developed for Consigli’s work associated with Orsted at the NY O&M Hub. The project takes place in an existing building. The building will be vacant during renovation work.

SITE LOCATION

The construction site is located at 22 Research Way E. Setauket, NY 11733 . The building is situated within an active industrial park. Work will take place mainly inside of the existing warehouse building, but there is also some scope of work outside the building in the existing parking area. There is work on the roof as well as on the 1st and 2nd (mezzanine) floors.

EMERGENCY TYPE

The following situations are considered emergency response actions and should be handled in accordance with the procedures outlined in this plan.

-

- Serious Injury/Fatalities

-

- Fire/Explosion

-

- Structural Damage/Collapse

-

- Weather or Geological Event Classified as an Act of God

-

- Environmental Incident

-

- Traffic Disruption

-

- Utility Damage

-

- Illegal Activity

-

- Labor Problems

-

- Bomb Threats/Military Ordinance Unearthing

-

- Acts of Terrorism

When reporting an emergency, please provide the following:

• Your location, phone number, and name;

• The location of the incident (building name, floor and room number);

• Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

• The safest route to the incident

Crisis Response Protocol:

-

- Attend to the injured

-

- Post person at access to work area, only allow access to emergency responders

-

- Record names/addresses of witnesses

-

- Do not allow media on site

-

- Refer all media inquiries to home office (See “Crisis Response Cards”)

Back– End of Emergency Response Plan

Emergency Contact Names and Numbers

CC Superintendent: Brian Fusaro (646)477-7363

CC Project Manager: Geoff Schwartz (347)443-2855

CC PX: Sean Payton (631)278-2004

CC Regional Safety Manager: Shawn Kenney (617)918-3012

Local Police Precinct

Suffolk County Police Dept (Emergency Number) 911

Suffolk Country Police Dept (Non-Emergency) (631)854-8600

Local Fire House

Setauket Fire Dept. (Emergency Number) 911

Setauket Fire Dept. (Non-Emergency) (631)941-4900

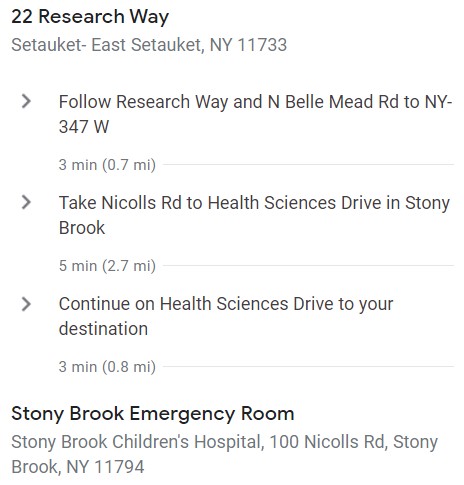

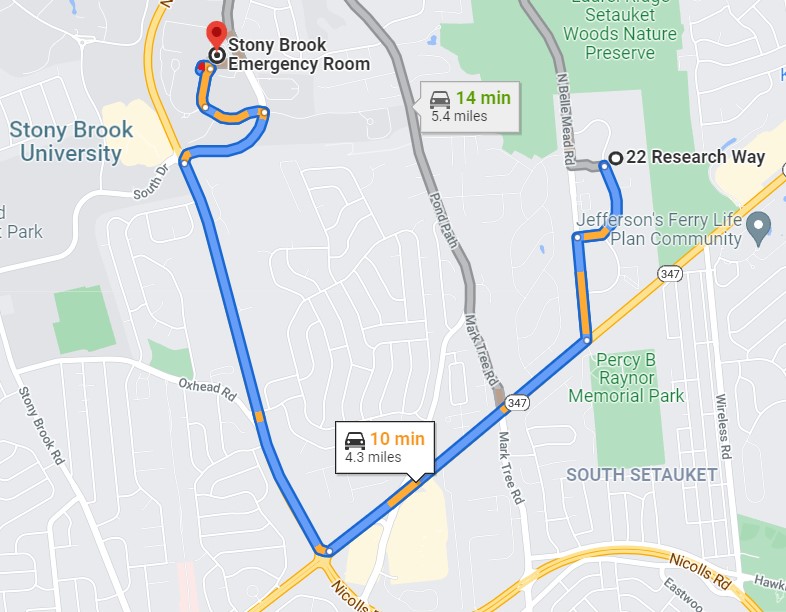

Closest Hospital

Stony Brook Hospital

101 Nicolls Road, Stony Brook NY 11794

(631)444-2499

Utilities

National Grid – Gas (800)490-0045

PSEG – Electric (631)755-6900

Back– End of Emergency Contact Names and Numbers

Medical Facilities

Stony Brook Emergency Room

100 Nicolls Road, Stony Brook NY 11794

(63`1)444-2465

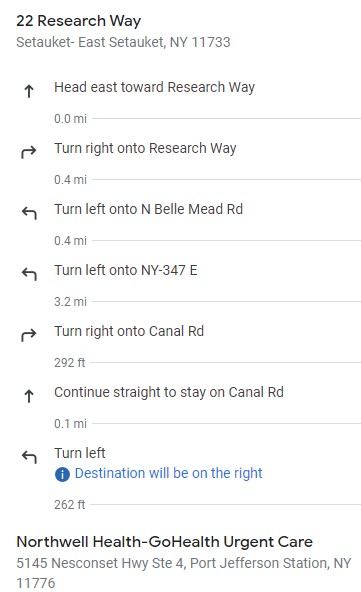

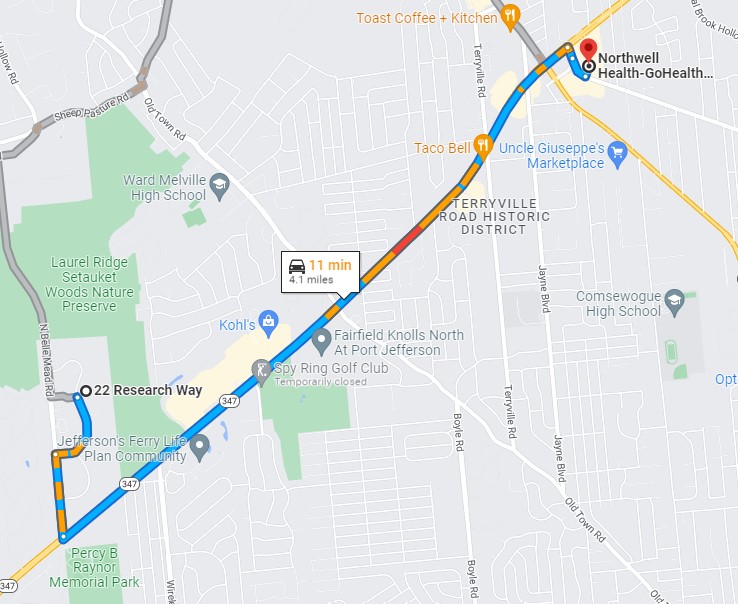

Northwell Health-Gohealth Urgent Care

5145 Nesconset Hwy Ste, Port Jefferson Station, NY 11776

(631)315-6755

Back– End of Medical Facilities

Site Safety Plan

A Consigli designated individual shall wait at the entrance to the work area to escort Emergency Services personnel as they arrive.

Scope of Proposed Operations: This site specific safety plan will cover all work under Consigli’s contract work with Orsted. The project will be devised into separate phases of work – sitework, demo/enabling, rough in, and finish. The proposed start of the project will be in November, 2022, and has an approximate 18 month project schedule.

The sitework scope will begin with stripping of the concrete and asphalt in the parking lot area. Some underground MEP work will take place including new sewer lines, new underground electrical, and new water lines. The parking lot will get new curbs and sidewalks, electric gates, and new EV charging stations, in addition to new paving.

On the inside of the building, demolition work will precede any new construction work. The demolition is selective and is non-structural. Materials to be demolished mainly consist of old MEP services as well as typical office finishes, such as carpet, drywall, etc. Once demolition is complete, rough in phase will begin. There will be new structural steel installed. New MEP systems will be installed. New framing and drywall will be installed. Drywall will be taped and painted. New rooftop units will be installed on the roof in order to support the new MEP systems being installed. Finish phase includes installation of new flooring, new tile, new ACT ceiling, new bathroom fixtures and partitions, along with typical MEP finishes.

Work on the 1st and 2nd floors will run concurrently. At its peak, the project will have approximately 40-50 workers representing various construction trades.

COVID-19: There is a site-specific COVID-19 safety plan developed for this job. It is available upon request. All workers entering the site will need to comply with the plan. The plan may be updated, based on changing regulations.

Adjacent Properties: Consigli’s work will take place within the existing building. At no point should any employee from the public enter the work area for any reason. In order to ensure this, all entrances to the work area will be secured and the perimeter of the jobsite will be fenced off. Should an employee be approached by non-project personnel, Consigli should be notified immediately. All egress and travel paths within the work area are to remain open and unimpeded at all times. Any challenge with coordination of deliveries/load out shall be brought to Consigli’s attention. At no time should construction personnel enter any adjacent properties.

Identify the specific route in and out of the construction site (Traffic Management): Consigli and subcontractor personnel will enter and exit the building through one of the existing entrances. This may change as construction progresses. All deliveries and waste removal will be coordinated and any impacts to the building will be clearly identified. Any change to this plan shall be coordinated with the Consigli Superintendent. All deliveries must be scheduled in advance. There is a potential that the owner will store material in the warehouse prior to construction completion. Consigli will coordinate access with ownership.

Personnel Protective Equipment (PPE): All workers will wear hard hats, high visibility shirts/vests, and safety glasses at all times. All personnel performing work with their hands shall be required to wear gloves that are appropriate to the task. When not performing actual work with their hands, workers will be required to have them available for immediate use. Face shields will be required for all personnel who are performing overhead work, using metal chop saw, or any type of metal grinding.

Designated work hours (any work outside these hours must have prior Consigli approval): Work will take place during regular business hours of, Monday – Friday 7:00am to 6:00 pm. In addition to these hours, off hours work may also take place, but off hours work is expected to be minimal. Precise hours will be discussed and conveyed to ownership. Deliveries must be coordinated with the Consigli superintendent, with at least 48 hours’ notice.

Shutdowns: Part of Consigli’s scope of work will be to tie new systems into the existing systems operating within the building. Shutdowns will be coordinated as needed. As the building is unoccupied, impact is expected to be minimal.

Evacuation Plan (RACE, and Routes of Egress): Please refer to the Evacuation Plan attached. All employees shall attend the Project Safety Orientation. At the orientation, workers will be made aware of the evacuation plan, the muster point, and general safety rules and regulations. Workers will also present Consigli with any applicable training documentation. The orientation verification, along with copies of training documents will be filed on site and entered into the electronic orientation log.

Emergency Management Response: In the event of an Emergency the construction workers shall leave the building immediately. Point of assembly/muster shall be as defined in the attached Evacuation plan. In the Event of a DISASTER, the Superintendent or Safety Manager shall instruct the construction workers to leave the site or remain in place and await further instruction.

When reporting an emergency, please provide the following:

• Your location ( 22 Research Way E. Setauket, NY 11733) phone number, and name:

• The location of the incident (building, floor and room number);

• Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

• The name and amount of the material spilled (if applicable); and

• The safest route to the spill (if applicable).

** Please review chapter 8 for additional details.

Pre-task Plans: Pre-task Plans or Job Safety Analyses shall be conducted prior to any and all operations. Said plan is to be reviewed with all involved personnel performing that particular task, signed by all workers, including their supervisor, and filed on site. The purpose of the PTP/JSA is to discuss the work ahead for the day, ensure the availability of tools, equipment, and material, and convey the safe work plan to all workers on site.

Fall Protection: All workers exposed to a fall of 6′ or greater shall be protected by guardrails, safety nets, or personal fall arrest systems. This includes, but is not limited to, steel erection, roofing, scaffold erection and dismantling, overhand brick laying and pre-cast concrete related work. Holes greater than 2” will be covered with acceptable material (3/4” plywood or ½” steel) which will be secured and marked with high visibility paint (cover must be able to withstand two times the maximum intended load). Covers will stay in place until the hole/penetration has been filled. The use of safety monitors is prohibited.

The only anticipated fall exposures are on the roof during the installation of the roof top units and associated piping, duct, or conduit installation. Fall exposures are intended to be limited by the installation of guard rails at the perimeter of the roof. Skylights will also have to be protected.

**Review Chapter 13 for more detail

Crane: Rooftop HVAC units will be rigged and installed on the roof via crane. The crane will sit in the existing parking lot area. The crane must have a current 3rd party inspection. The contractor shall prepare and submit a detailed pick plan showing weights and capacities at the radii in which the crane will operate. All individuals that are rigging and/or signaling shall possess certification of training and shall submit same to Consigli. The swing radius shall be protected at all times. Tag lines will be installed on each RTU when they are being lifted.

Work on Ladders: All work on step ladders/straight ladders will be done correctly per manufacturer’s recommendations. Ladders must be inspected and be found in good condition before use. Step ladders will not be used as a form of access to a walking/ working level. Also, all straight ladders will be secured when installed for use. All ladders in use on site must be IA or IAA rated.

Scaffold and Elevated Work Platforms: All scaffolding shall be inspected daily, by a competent person designated by each contractor, before each shift. Scaffold inspections shall be documented on installed scaffold tags. Said Scaffold Inspection Tags shall be located at the stair tower/access point to each scaffold section. A scaffold inspection guide will be provided to each designated person by Consigli to aid them with their inspection, which must be turned in after the inspection is completed. For baker scaffolds, tags and inspection checklists are not required, though competent person inspection is still required. Fall protection is required at all times during erection/dismantling operations if workers are exposed to a fall of 6’ or greater. All workers using a scaffold must possess documentation of training.

Scissor lifts: Area and ground conditions in the intended work area will be inspected for suitability. Scissor lifts shall be inspected daily before each shift by the subcontractor using it. Inspection shall be documented on a scissor lift inspection form. Subcontractor employees performing work from a lift shall provide documented proof of training. Workers shall be tied off at all times when using a scissor lift.

Haz Com/Global Harmonization: All contractors bringing materials/chemicals on site shall provide Safety Data Sheets to the Consigli project team.

-

- SDS sheets shall be kept on file in Consigli Construction’s project office

-

- All SDS sheets shall be readily accessible.

Fire Protection: All fire protection and hot work will conform to the Fire Code as well as all applicable codes and regulations. When on site, compressed gases and fuel will be housed in the appropriate cage. On a daily basis, any spark producing tool or work practice will require an internal hot work permit. This will be obtained from the Consigli Superintendent. Once hot work has ceased for the day and fire watch has been completed, the permit will be closed for the day by returning the permit.

**Review Chapter 17 for more detail.

Electrical: The electrician will be responsible for all temp power and any temp lighting that may be needed. They will coordinate all lock out tag out procedures regarding electricity. All electrical tools, cords and equipment must be in good working order. To that end, all electrical tools and components must be visually checked on a daily basis. Any tools with damaged cords or damaged cords must be taken out service immediately. All cords must be equipped with a ground pin. Flat three wire cords are not allowed. Only SJO and SJT, or other similarly rated cords, shall be used. Subcontractors will be responsible for task lighting in the event that lighting above the OSHA standard is required for a particular work task. The electrician will coordinate all lock out tag out procedures. GFCI will be tested by the electrical contractor to assure proper function with a log filed with Consigli on a monthly basis. Any live work will be conducted in accordance with NFPA 70E, though the need to work live is not anticipated.

Confined Space: Any work in what may be considered a confined space shall be discussed with Consigli prior to the prosecution of said work. Any work in a permit required confined space shall require training for workers involved with the entry, a permit, air monitoring, constant ventilation, and a non-entry retrieval system. The permit will be closed out when the entry supervisor assures that all workers have exited the space. The permit shall be returned to Consigli.

** Please review chapter 21 for additional details.

Designated First Aid Plan: Incidents shall be reported within 24 hours. Each subcontractor is required to have a fully stocked first aid kit for use by their employees.

Restricted Areas: Contractors are prohibited from entering areas of the building other than where work has been previously authorized and scheduled.

Materials Management: Getting materials into and out of the project will be a challenge that needs to be adequately planned. All deliveries are to be scheduled with the Consigli Superintendent a minimum of 48 hours in advance. A comprehensive Activity Hazard Analysis shall be done on all materials that will be hoisted and placed into or on the building. Only materials which will be used/installed in a reasonable amount of time will be delivered to the site. Attention must be paid to structural analysis in regards to loading of existing floors with material and equipment.

Silica: Any activity which can produce silica dust will use engineering controls to keep dust to a minimum. There will be no dry cutting of any masonry material allowed. If water cannot be used, then a HEPA dustless vacuum system shall be used. An exposure assessment shall be required of any worker involved in any activity not covered by table 1 of the OSHA Silica regulations for construction. An exposure assessment will also be required for any activities covered by table 1 if the engineering controls listed in same are not followed.

Mold: Mold issues are not anticipated to be prevalent on this project, however if mold is discovered Consigli’s mold remediation policy will be implemented and followed.

Equipment issues: All operators will be required to have in their possession, all appropriate licensing and training as required by OSHA and the State of NY. All safety devices and warning alarms must be in good working order and all leaks are to be repaired immediately. All equipment will be used in accordance with the manufacturer’s recommendations for safe usage and have its operator’s manual as well as an extinguisher with it at all times. All equipment must be inspected daily and a copy of the inspection turned in to Consigli at least on a weekly basis. Any subcontractor using heavy equipment shall have a spill kit of adequate size on site in the event of any leaks or spills.

Exposure to the Visitor: All visitors will sign a visitor’s waiver prior to accessing the site. Visitors shall be required to wear PPE while on site. The work area shall remain secure at all times.

Planning: The project team, as well as Consigli Safety Department, will meet with each subcontractor before they start to review their Site Specific Safety and Health Program and all project specific Job Hazard Analyses. The project team shall be an integrated mix of superintendent, project manager, safety department, and the foreman and project manager from the subcontractor. If after reviewing programs and meeting with the individual subcontractor, the team is satisfied with the risk control direction, they will be permitted to begin work.

Orientation: Prior to accessing the job site, workers shall participate in the Consigli Orientation program. At the orientation, workers shall present their credentials (OSHA cards, certifications of fitness, aerial/scissor lift training cards, rigging/signal cards, etc.). Consigli shall take copies of same for records. Workers will then be issued an individually numbered orientation sticker, which will be affixed to the workers’ hard hat.

Environmental: A hazardous material survey was conducted by ownership. It is available for review at any time by any project personnel. The hazardous material survey indicated that there is asbestos in the existing roof flashing including parapet base flashing. Ceiling joists and girders were found to be a lead containing material. Several existing elements to be removed are classified as universal waste including fluorescent and incandescent light fixtures, halogen bulbs, emergency exit light fixtures, thermostats, smoke detectors, and light ballasts. These materials all require special handling and will must not be disposed of as general construction debris.

Back– End of Site Safety Plan