Project # 2928 – BSU – Stonehouse

135 Burrill Ave, Bridgewater MA 02325

Emergency Response Plan

ALL EMERGENCIES SHOULD BE REPORTED BY CALLING 9-1-1

SITE INFORMATION

This Emergency Response Plan (E.R.P.) is specifically developed for Consigli Construction work associated with this Project.

SITE LOCATION

The construction site is located at Stonehouse @ 135 Burrill Ave, Bridgewater MA 02325. The location for the project field office is currently at the Project jobsite (notifications of any changes will be provided). When determined, the field office will become the Emergency Operations Center (EOC).

EMERGENCY TYPE

The following situations are considered emergency response actions and should be handled in accordance with the procedures outlined in this plan.

• Serious Injury/Fatalities

• Fire/Explosion

• Structural Damage/Collapse

• Weather or Geological Event Classified as an Act of God

• Environmental Incident

• Traffic Disruption

• Utility Damage

• Illegal Activity

• Labor Problems

• Bomb Threats/Military Ordinance Unearthing

• Acts of Terrorism

When reporting an emergency, please provide the following:

-

- Your location, phone number, and name;

-

- The location of the incident (building name, floor and room number);

-

- Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

-

- The safest route to the incident

Crisis Response Protocol:

• Attend to the injured

• Immediately contact Bryan Kingsbury (508)808-9359

• Post person at front gate, only allow access to emergency responders

• Record names/addresses of witnesses

• Do not allow media on site

• Refer all media inquiries to home office (See “Crisis Response Cards”)

A Consigli designated individual shall wait at the East Campus Commons entrance to escort Emergency Services personnel as they arrive.

The following is a list of the Chain of Command/Call Hierarchy on the project for establishing lines of succession during communication involving all emergencies.

Back– End of Emergency Response Plan

Emergency Contact Names and Numbers

1. First call: 911 Fire or Police

2. CCC Superintendent: Mike O’Brien (508)962-2245

3. CCC PM: Stacy Zannottti (508)294-0420

4. CCC PE: Patrick Nolan (617)352-3383

5. CCC GS: Dean Archambault (508)958-0138

6. CCC PX: Jodi Staruk (508)922-0822

7. Corporate Safety: Bryan Kingsbury (508)808-9359

8. Safety Manager: Eddy Pellerin (508)962-3974

Bridgewater State University

Director of Capitol Planning: Barbara Masaitis (508)279-5194

Facilities Manager: Dave Coonan (508)443-7155

Bridgewater State University Campus Police (509)531-1212

Additional Contacts

Bridgewater Police Department- Non-Emergency (508)697-6118

Bridgewater Fire Department- Non-Emergency (508)697-0900

Bridgewater DPW (508)378-1620

Bridgewater Water Department (508)378-1620

NSTAR Gas Co. (800)592-2000

National Grid-electric (508)897-5500

Dig Safe 881

Environmental Consultant

ALG Environmental Consulting, LLC

20 Island Pond Road Derry ,NH 03038

Allen Grinnell (603)216-1350

Back– End of Emergency Contact Names and Numbers

Medical Facilities

AFC/ Doctors Express Non-Emergency

(781)322-7300

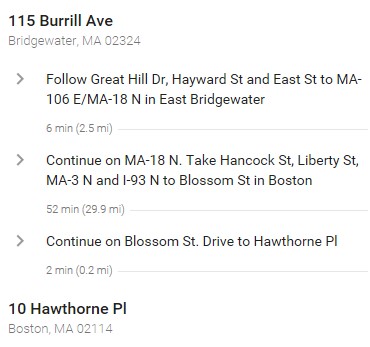

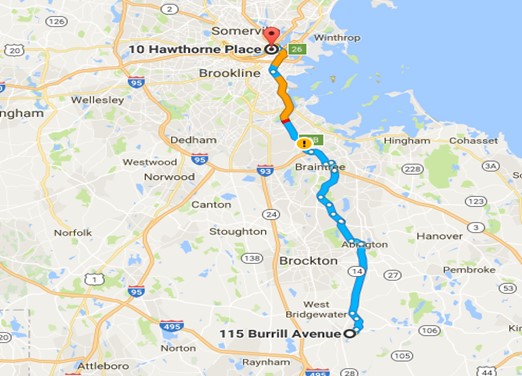

10 Hawthorne Place, Suite 114 Boston, MA 01226-6427

Good Samaritan Medical Center Non-Emergency

(508)427-3233

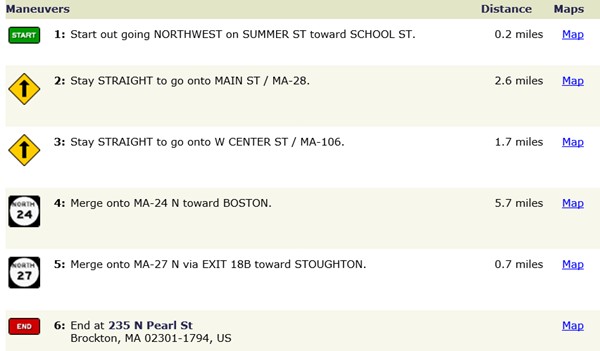

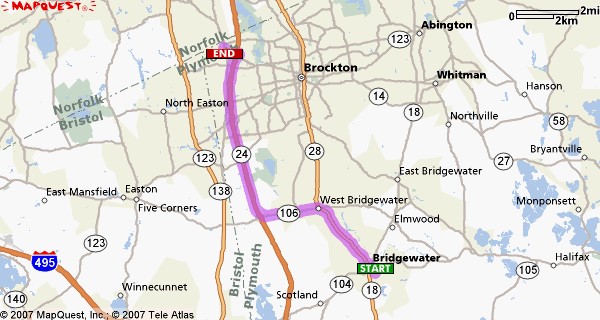

235 North pearl Street Brockton, MA 02301

In case of emergency a Consigli representative will be dispatched to the Main entrance of the building to meet the responding Emergency Personnel and advise the individual in charge of the location of any chemicals or hazardous substances that may be present on any of the floors. MSDS/SDS sheets will be readily available if needed by the Fire Dept.

In the event of a serious injury requiring the assistance of EMS the injured worker will be kept as comfortable as possible. Emergency first aid if necessary will be administered. Under no circumstances will the injured person be moved unless the worker’s life is in danger because of fire or calamity. A worker will be assigned to meet the medical personnel at the above location to direct them to the location of incident.

In the event an evacuation is required all personnel at this job site will assemble on the lawn next to the guard shack at the entrance to the Moakley parking lot. foreman for each company will meet at that location and take a head count of their staff and report to Consigli Superintendent. If for some reason a worker is unaccounted for, the fire department will be notified of the last location where the worker was observed.

Directions to Good Samaritan Medical Center

Back– End of Medical Facilities

Site Safety Plan

Scope of Proposed Operations: This project, starting in May 2023 with an expected completion date of August 2023 the project involves the complete renovations of 10 Bathrooms on all 5 floors of the Shea Durgin Building. Project hours will be between 7:00am and 3:30pm Monday through Friday unless otherwise approved by Consigli Construction. At its peak this project will employ 10-30 workers representing several different trades. Fire sprinkler system will remain active during construction and heads will be moved as needed… No exterior façade or site work is planned.

PURPOSE: The purpose of this Site Specific Safety and Health Program is to illustrate Consigli’ s approach to identifying project specific hazards and controls and how said risk is managed through a comprehensive Safety and Health Program.

S.A.F.E.: Staying Accident Free Every Day is the Safety Mission that forms the very foundation of the Consigli Safety Culture. The S.A.F.E. mission, which is supported by technology, (Predictive Solutions internal auditing instrument which identifies and defines leading indicator related information); Leadership (Empowering our team members to assure safe projects); Humanization (Protect the ones you love by protecting yourself); Jobsite Gym (Morning warm-ups, stretch and flex); Training (Integrating sub-contractors into the Consigli Safety Culture); and Lean (nothing hit the ground), is the driving force behind Consigli’ s drive to our vision – ZERO. ZERO is the philosophy that all accidents are preventable and that no accident is acceptable. The S.A.F.E. mission is the guiding force to achieving the Consigli Safety Vision which is ZERO.

Identify the specific route in and out of the construction site (Traffic Management): All deliveries and waste removal shall be done using the entrance on North elevation and shall be coordinated with CCC with at least 48 hours’ notice. All contractors will be responsible for adhering to BSU/Bridgewater restrictions and regulations in regards to driving, parking and delivering materials. Pedestrians will be given the right of way at all times. Parking will be designated.

Designated work hours (any work outside these hours must have prior CCC approval): All work shall take place during business hours, Monday – Friday 7:00am to 3:30pm, any work which may need to take place outside of these hours will need to be approved by the CCC Superintendent.

Pre-task Planning: A Job Safety Analysis shall be conducted for each work task to be performed on a weekly basis. JSA’s shall be reviewed initially with all involved personnel performing that particular task, signed by all workers including their supervisor and filed on site.

Activity Hazard Analysis (AHA): An AHA/JHA depending on level of hazard shall be conducted for each identifiable feature of work to be performed. The AHA/JHA shall be submitted to Consigli superintendent/supervisor. AHA/JHA shall be reviewed weekly and signed by all workers, including their supervisor. All involved personnel performing that task shall be involved in the planning.

Post Incident Review: Any incident that results in a recordable injury will require a post incident review. The worker who was injured along with their foreman/Safety Personnel/PM/Sup/etc… will need to fill out Appendix ?? (post incident review form) and attend this meeting. At this meeting they will re-emphasize their commitment to safety, determine chronology of events, identify contributing factors, identify root cause, provide improvement plan to prevent reoccurrence and discuss disciplinary actions taken (if any). Findings from this meeting will be shared/disseminated with all contractors on site to prevent reoccurrence.

Services: Any compromises to BSU Campus services during the work performed will be handled accordingly

• Adjacent areas shall be notified before all work that may compromise service or impact students, visitors or staff.

• During weekly project meetings, if needed upcoming work that may compromise service or impact BSU shall be talked about with construction managers and scheduled for off shift if the group decides it will be needed.

• The on-site superintendent shall make weekly contact with all adjacent staff for the duration of the project.

Demolition: Prior to the start of demo operations, the contractor performing demo will confirm that all utilities leading into the area have been made safe. The electrician will disconnect and lock out all electrical, the plumber will do the same with any plumbing lines, and the HVAC subcontractor will do the same on the HVAC piping and duct work. Lock out tag out will be reviewed during the pre-construction safety meetings to assure disconnect and responsibility for protection of existing utilities is safe for any construction activities to commence. In spaces where some electrical or mechanical must remain live, a color coding system will be utilized for easy identification of live utilities that must stay active and utilities that must be removed. Any and all utilities spray painted Red are not to be touched and are need to be protected during all operations. Utilities spray painted Green are to be removed as part of the selective demolition process only after lock-out/tag-out has been confirmed and utilities tested. If any utilities are unmarked, they shall be considered live. The demo contractor will be responsible for completing CCC demo checklist prior to the start of any work in their target areas

Excavations: Other than saw cutting of basement concrete floor and subsequent excavation for new sewer line (2 – 3 foot depth only), there will be no significant excavation. If at some point exterior excavation needs to take place, all required permitting will be obtained before any excavating is to begin. If necessary, tabulated data/engineering for shoring and shielding systems will be obtained and available on site at all times when in use. All excavations will be inspected by a competent person on a daily basis. Written excavation inspections will be done if the excavation exceeds 5’.

-

- Dig Safe Notification – dig safe number will be obtained and posted in the site office.

- Jackie’s Law (520CMR 14.00) will be strictly adhered to and permits must be obtained. A copy will be posted in construction office.

- Copies of shoring engineering and tabulated data sheets for all trench boxes or other shoring/shielding systems brought on site will be provided to CCC and be kept in construction office

**Review Chapter 19 for more detail

Fall Protection: Although it is not anticipated that there will be any fall exposures over 6’ in height (there is no exterior, roof, or shaft work) it will still be communicated that all workers exposed to a fall of 6′ or greater shall be protected by guardrails safety nets or personnel fall arrest systems. Holes greater than 2” will be covered with acceptable material (3/4 plywood ½ steel) which will be secured and marked hole and capable of supporting 2x the intended load (cover must be able to withstand 2x times the intended axle load). Covers will stay in place until the hole/penetration has been filled with duct or Pipe riser which extends above the deck. Building perimeters (to be protected with cable guard rail system with turnbuckles to be installed for all straight runs and any straight run over 100 feet.

Although it is anticipated that no work is to begin on the roof it must be determined what method of fall protection will be implemented should access to roof be necessary. The use of safety Monitors is not allowed!!!

**Review Chapter 13 for more detail

Work on Ladders: All work on step ladders/straight ladders will be done correctly per manufacturer’s recommendations. Any worker who is on a step/straight ladder and could be exposed to a fall greater than the height of their work on the ladder will be required to install a form of fall protection. Step ladders will not be used as a form of access to a walking /working level, also all straight ladders will be tied of when installed for use. Only ladders with a rating Type 1A or 1AA will be allowed on Consigli projects.

Scaffold and elevated work platforms: All scaffolds/material hoist supported frame, pipe staging and baker staging will be inspected daily before each shift by a competent person designated by each individual contractor who will be using it, which will be documented on Inspection tags located at the stair tower/access point to each section. if installed a scaffold/material hoist inspection checklist will be completed prior to the beginning of each shift and filed in the site office. This will be completed by the designated person from each individual contractor must complete an inspection every day the scaffold/material hoist is used by his/her employees. A scaffold inspection guide will be provided to each designated person (upon request) by Consigli Construction to aid them with their inspection. All contractors who will be erect scaffold will provide CCC with certification/Qualification of scaffold erection training as well as an erection/dismantling plan. Fall protection is required 100% during erection/dismantling. Peery bakers are not allowed on this site. Overhead protection will be provided for all access points to any buildings located under any form of scaffolding/material hoist.

Aerial/Scissor Lifts: If aerial lifts are required (beyond the initial use for exploratory and Haz mat identification) the area and ground conditions, in the intended work area, will be inspected for overhead power lines, sink holes, covers, or any other unsafe conditions which cause an unsafe incident. Aerial lift platforms will be inspected daily before each shift by a competent person designated. All who will be performing work from an aerial lift will show documented proof of training prior to using the lift. Steel plates or equipment mats will be placed on the ground above any utility/ underground structures if there will be Aerial lifts operating directly over them. Workers will be tied off at all times when using an aerial lift.

Global Harmonization: All Materials and chemicals used on-site will have SDS provided before being brought onsite.

• MSDS/SDS sheets on file in Consigli Construction’s Site Safety Plan

• All MSDS/SDS sheets shall be readily accessible.

• Subcontractors will be responsible for inspecting existing ground conditions and notifying Consigli if there are any issues prior to lift use.

** Please review chapter 20 for additional details.

Fire Protection: A Hot Work Permit will be required for any activity that generates heat, sparks or has an open flame. This will be coordinated through the Consigli, Boston College and Newton Fire. (If needed). Any hot work will stop one hour before the regular end of the day work stoppage. Flammables will not be stored inside the building or left overnight on the scaffold or in the building. All combustible or flammable materials will be stored in an appropriately rated lockable cabinet located no closer than 50 feet from the nearest structure. Fire extinguishers will be provided for every 3000 square feet. They will be installed on job made stands and conspicuously located throughout. They will be part of the daily inspection with extinguisher log completed monthly. Storage of any acetylene cylinders will be done in a secure and upright area, with good ventilation. This will be a strict no smoking project. All penetrations leading outside of the construction area will be fire stopped using approved fire rated material prior to the end of each shift.

**Review Chapter 17 for more detail.

Electrical: All electrical tools, cords and equipment must be in good working order. To that end, all electrical tools and components must be visually checked on a daily basis. Any tools with damaged cords or damaged cords must be taken out service… All cords must be equipped with a ground pin, flat three wire cords are not allowed. SJO and SJT or other similarly rated cords only shall be used. The electrician will be responsible for all temp power and any temp lighting that may be needed. They will coordinate all lock out tag out procedures. All temporary power for the project will be installed on protected and dedicated circuits with 100% GFCI protection. GFCI will be tested by the electric contractor weekly to assure proper function with a log book filed with CCC monthly. No live electrical work will be conducted. No live electrical work will be conducted per NFPA 70E.

**Review Chapter 26 for more detail

Crane: Location and set up will be reviewed with crane operator prior to set up andpick. All lifting operations will require that the operator and any involved contractors follow the steps listed below as well as in CCC Crane Safety policy

-

- All Hoisting equipment will have an up to date 3rd party inspection certificate with the equipment which will be copied and filed in the office trailer.

-

- All lattice boom cranes will have an independent 3rd party inspection completed each time one is set up on the project.

-

- All workers working with the crane shall have all appropriate signalmen/rigging qualifications.

-

- All equipment operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the State of Mass.

-

- NCCO certification will be required for all crane operators who will be operated on site along with an evaluation letter provided by the owner for the operator and the crane to be used on site.

-

- All underground vaults and existing utilities will be marked before any excavation can begin as well as before any crane is set up.

-

- Cribbing for outriggers shall be at minimum 3X the area width of outrigger floater. (Cranes only)

Utility Exposures: Before any work is started that may impact known utilities, all due care will be taken to identify the locations of underground utilities. Subcontractors must review field conditions, as-built drawings, etc. to ensure that there is no impact to the utilities.

.

Equipment issues: All operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the Commonwealth of MA. All safety devices and warning alarms must be in good working order and all leaks are to be repaired immediately. All equipment will be used in accordance with the manufacturer’s recommendations for safe usage and have its operators manual as well as an extinguisher with it at all times. Subcontractors who will have equipment on site will be responsible for having a spill kit available at all times.

** Please review chapter 24 for additional details

Confined Space: A written plan will be needed to work in any tanks/vaults and crawl spaces during this project which have been designated permit confined spaces by CCC, this plan must include air monitoring.

** Please review chapter 21 for additional details.

Designated First Aid Plan: All injuries no matter how minor must be reported to Consigli Superintendent immediately. The superintendent will then report all injuries to the CCC Safety Director. A fully stocked first aid kit and blood borne pathogens kit shall be maintained on the project site. Only properly trained personnel will administer first aid. Consigli Construction shall follow Site Safety Plan for first Aid. Report any incidents to the Safety Director.

** Please review chapter 1 and 27 for additional details.

Substance Abuse: As a condition of employment, all Consigli personnel are required to submit to a urinalysis test for determination of the presence of illegal substances. A positive result will disqualify the applicant for employment on this project.

Evacuation Plan (RACE, and Routes of Egress): Please refer to the Evacuation Plans attached. All Consigli employees shall attend the Project Safety Orientation. Consigli Construction’s Job Supervisor will conduct a safety orientation talk to each employee and subcontractor to site specific fire safety protocols.

Roof Work: Before any work is to begin on the roof it must be determined what sections of the roof will be worked a method of fall protection will be implemented (100% tie off, guard rails, flagging etc. the use of safety monitors is not allowed) Holes greater than 2” will be covered with acceptable material (3/4 plywood ½ steel) which will be secured and marked hole (cover must be able to withstand four times the intended load). Covers will stay in place until the hole/penetration has been filled with duct or Pipe riser which extends above the deck. All roof penetrations or existing roof top curbs will be made water tight by the end of shift.

Emergency Management Response: In the event of an Emergency the construction workers shall leave all 3 of the building immediately. Point of assembly/muster shall be located next to the pedestrian bridge located in the back parking lot on Newbury Street. In the Event of a DISASTER, the Superintendent or Safety director shall instruct the construction workers to leave the site or remain in place and await further instruction. The following steps should be taken in the event of an emergency

When reporting an emergency, please provide the following:

-

- Your location (Stonehouse 135 Burrill Ave, Bridgewater MA 02325) phone #, and name;

-

- The location of the incident (building name, floor and room number);

-

- Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

-

- The name and amount of the material spilled (if applicable); and

-

- The safest route to the spill (if applicable).

** Please review chapter 8 for additional details.

Personnel Protective Equipment (PPE): All CCC and sub-contractor workers will wear hard hats and safety glasses at all times. All CCC personnel performing work with their hands shall be required to wear gloves that are appropriate to the task. When not performing actual work with their hands, workers will be required to have gloves available for immediate use. Face shields will be required for all personnel who are performing overhead work, using metal chop saw or any type of metal grinding. All welders will be required to have hard hats with integral welding shields.

Restricted Areas: Contractors are prohibited from entering any adjacent Areas/buildings unless work has been previously authorized and scheduled. It is important that workers do not park in/in front of adjacent driveways during construction. All workers will try to limit their impact on surrounding areas.

Lean Requirements: No materials shall be delivered to the site earlier than 3 days before said materials are to be installed/put into place. If materials have to be delivered before that 3 day time period, subcontractor shall get prior approval from Consigli Superintendent. Because of this, notification / scheduling is required for all deliveries to the site. Subcontractors must notify Contractor at least 24 hours in advance. Contractor has the right to refuse any deliveries not properly scheduled or due to logistical constraints as necessary .All subcontractors’ delivered materials shall be placed on wheeled carts, wheeled racks or in wheeled bins so as to necessitate easy relocation in the event materials need to be moved. Carts, racks, or dollies shall not exceed manufacturers intended weight loads. Materials/tools can be delivered and stored on pallets only if pallet jacks are delivered simultaneously with said delivery to provide for ready mobility. Additionally, pallet jacks need to remain in immediate area. Each subcontractor will need to supply their own pallet jacks for their own materials and keep their pallet jack within reasonable distance at all times. All work stations shall be provided with wheeled trash bins for immediate placement of all debris produced as a part of the subcontractors operations.

Minimum Site Safety Requirement: All Consigli workers, and any subcontractors, shall have, at a minimum, an OSHA 10 Hour Construction Safety Outreach training certificate and shall provide documentation of training.

Materials Management: Materials management, getting materials into and out of the project, will be done through existing service elevators and loading dock. Getting materials into and out of the project will be a challenge that needs to be adequately planned. All deliveries are to be scheduled with the CCC Superintendent. A comprehensive Activity Hazard Analysis shall be done on all materials that will be hoisted and placed into the building. Only materials which will be used/installed in a reasonable amount of time will be delivered to the site. Attention must be paid to structural analysis in regards to loading existing floors with material and equipment

Steel Erection: Any subcontractor associated with the structural steel erection will comply with the following. Provide proof of training of subpart R training as well as fall protection training for all workers will be required before start. Consigli will release documentation when column footings reach 75% of breaking strength. Once this has been achieved, CCC will furnish to the steel erector the “approval to begin steel erection form”.

The steel erection sub will be required to submit a detailed erection sequencing plan that illustrates crane locations and capacity of cranes at those locations. Fall protection will be determined for connectors after pre-construction meeting with sub is held. Fall protection will be required at 6’, at all times during steel erection

Once decking is complete and all required fall protection is installed, CCC will walk the area with the steel erection subcontractor. Provided all required elements of fall protection are in place, CCC will complete and give a copy of the “custody of fall protection” form to the steel erection subcontractor. Maintenance and overall responsibility of the fall protection system will fall to CCC.

** Please review chapter 16 for additional details

Back– End of Site Safety Plan

Environmental Emergency Contact and Management Response

Consigli identified Emergency Response Subcontractor;

Name: Cynn Environmental Services, Inc. # – (781)341-1777

100 Tosca Drive Stoughton, MA 02072

Asbestos: A Hazardous Materials report has been prepared by ALG. Asbestos abatement will be completed by a licensed/certified contractor.The complete table and “List of Materials tested, Quantities, and Locations” can be found with the hazardous material report. This does not mean that asbestos could not still be found in other areas, caution must be used when working and if any workers identify any potentially hazardous substances then they should stop and notify their supervisor immediately. All identified asbestos will be fully abated by a licensed and regulated asbestos abatement contractor under a formal plan to be written, submitted and in accordance with the DEP.

IT IS THE RESPONSIBILITY OF ALL SUBCONTRACTOR FOREMEN TO REVIEW THE HAZOUDOS MATERIAL REPORT & CORRESPONDING ABATEMENT REPORT WITH THEIR WORKERS. A copy of the hazardous Material/abatement report will be on site at all times and available to anyone request it. All work and disposal will be done in compliance with state and federal regulations and standards. All workers on this project must have completed Asbestos awareness training prior to starting on this project.

Lead: All painted surfaces will be considered to be lead containing. Consigli workers who will need to perform work on these painted surfaces may need to disturb this paint by drilling, sawing, demo, fastening, or carpentry. In doing so they will use saws, drills, screw guns, impact wrenches, sawzalls, hand wrenches, ads, crowbars, hammers, and other hand tools. Consigli Construction does possess historical data to show that drilling, sawing, light demo, installation of hangers, hanging sheetrock, fastening, and carpentry do not put the employee above the action level. Despite this additional monitoring will be done. An exposure assessment will be done by all subcontractors for all task prior to when the full scale of this work is to take place. This does not mean that lead could not still be found in other areas, caution must be used when working and if any workers identify any potentially hazardous substances then they should stop and notify their supervisor immediately. All workers on this must have completed Lead Awareness training prior to starting on this project. Hand wash stations will be provided to ensure proper hygiene during the project. An exposure assessment will also be done for any task which will disturb any lead containing material.

Silica: Any activity which can produce silica dust will use engineering controls to keep dust to a minimum. A written exposure plan must be developed for all silica producing tasks that clearly defines the following:

1) A description of the tasks in the workplace that involve exposure to respirable crystalline silica.

2) A description of the engineering controls, work practices, and respiratory protection used to limit employee exposure to respirable crystalline silica for each task.

3) A description of the housekeeping measures used to limit employee exposure to respirable crystalline silica.

4) A description of the procedures used to restrict access to work areas, when necessary, to minimize the number of employees exposed to respirable crystalline silica and their level of exposure, including exposures generated by other employers.

There will be no dry cutting of any masonry material allowed; if water cannot be used then a dustless vacuum system consisting of HEPA dustless vacuum system will be used. Prior to the project going full scale an exposure assessment of a worker grinding and cutting a silica containing material while using the HEPA system an exposure assessment will be done to establish the silica exposure level if table one cannot be followed.

Polychlorinated Biphenyl’s (PCBs): At this time there are no activity’s which are planned which would disturb any surface with suspect amounts of PCB’s… This does not mean that regulated levels of PCB’s could not still be found in other areas, caution must be used when working and if any workers identify any potentially hazardous substances then they should stop and notify their supervisor immediately.

Light ballast unless labeled “No PCB’S” will be designated PCB containing, All PCB containing material shall be removed and disposed of in accordance with all local, state (MEMEP Special waste management rules 06-096-CMR 400) and federal regulations and be coordinated with BIDMC. All other inquiries or locations in regards to PCB containing material can be located in the Hazardous Material survey. If identified on any of the materials to be impacted, PCB‘s will be abated. Any and all PCB remediation will be performed by a licensed /qualified contractor

** Please review chapter 29 for additional details

Freon/Glycol: All Freon/Glycol materials will be removed from equipment and stored per manufacturer’s recommendations before it is disturbed, moved or removed. All workers who will be working with the above mentioned materials must provide CCC with certifications or qualifications. If not re-used, a disposal manifest will be provided to CCC.

Mold: Mold issues are not anticipated to be prevalent on this project, however if mold is discovered Consigli’s mold remediation policy will be implemented and followed.

** Please review chapter 22 for additional details

Mercury: All fluorescent lamps/thermostats are presumed to contain mercury vapor, which is a hazardous substance. Mercury-containing lamps associated with fluorescent light fixtures in areas designated to be renovated will be treated accordingly. All florescent bulbs removed during renovation will be collected, properly stored on site and given to the facility so as to be recycled or disposed of properly.

Noise: Noise exposure will be a concern so all operations must be coordinated with the Consigli Superintendent to limit any excess noise impact on the surrounding areas. All activity r task which may cause load noise will be restricted as needed so as to limit the impact on Guest/Members.

** Please review chapter 29 for additional details

Exposure to the Visitors, Staff and Residents: During all phases of construction pedestrian walkways around the project will be open and occupied. Some areas of project will be opened for construction at different times. Any pedestrian walkway under any type of scaffold or overhead hazard will be provided with overhead protection. At no time is any worker allowed to enter any of the adjacent buildings. Non fraternization with staff, members and students will be stressed with all subcontractor personnel during orientations.

Additional Controls: Prior to start of any work, all personnel involved in the project, including project managers must be:

1. Trained and orientated by Consigli Construction. Stickers will be issued and displayed on hard hats

Planning: The project team will meet with the staff before the project start to review any site specific safety and health requirements. The project team shall be an integrated mix of owner, architect, engineer and Consigli Construction personnel. If, after reviewing programs and meeting with the individuals, the team is satisfied with the risk control direction, personnel will be permitted to begin work.

Loss Exposures and Controls: All individuals working on this project will go through a comprehensive Safety Orientation which will cover all company safety rules, regulations and procedures, as well as communicating specific requirements set forth by BSU

Fraternization between construction employees and project owners, staff, veterans or visitors will not be permitted. Loud and profane language or clothing with offensive language will not be allowed on the jobsite. Extra efforts must be made to keep noise to a minimum when feasible.

Safety Spot Recognition Plan: The purpose of this plan is to instantly recognize workers “on the spot” for working safely and to reward those workers immediately. This will assist CCC reduce the complacency of workers on all of our projects. Members from the CCC and BSU project teams (Supers, PM, APM, PE,OPM, Architect, Owners, etc..) will be provided with 5$ Dunkin Donut gift cards prior to their walk on site. They are to present these cards to workers who are working safely and or those taking additional steps to work safely. After issuing the card, the name and hard hat sticker number of the worker as well as a brief description of what they were doing will be documented in a log that will be maintained in the field office. This shall be completed at a minimum of twice a week. It is required that different field staff take turns in issuing the cards to workers in the field. Also required will be the communication of who is be recognized to other sub-contractors/workers through foreman meetings and daily stand up’s. at the end of the project the sub-contractor who has had the most workers recognized will receive an appropriate acknowledgment from CCC as well as some type of reward that is to be determined by CCC field staff.

Badging/Site Orientation: All workers are required to be identified to BSU management/security 48 hours in advance(if required) to arriving on the project. All workers and visitors will check-in at the security desk daily if required.

All individuals working on this project will go through a comprehensive Safety Orientation which will cover all company safety rules regulations and procedures as well as communicating BSU requirements.

All personnel working on site shall have documentation of an OSHA 10 Hour Construction Safety Outreach Training minimally. Foremen are required to have documentation of an OSHA 30 Hour Construction Safety Outreach Training.

Fraternization between construction employees and project owners, tenants, or visitors will not be permitted. Loud and profane language or clothing with offensive language will not be allowed on the jobsite. Extra efforts must be made to keep noise to a minimum.

Back– End of Environmental Emergency Contact and Management Response