West Point Anderson Athletic Center

Emergency Response Plan

ALL EMERGENCIES SHOULD BE REPORTED BY CALLING 9-1-1

SITE INFORMATION

This Emergency Response Plan (E.R.P.) is specifically developed for Consigli Construction Management work associated with the West Point Anderson Athletic Center.

Memo from the President

FROM: Greg Burns, President

TO: Employees and Subcontractors

SUBJECT: Job Safety

Over the past several years we have made significant improvements to our occupational health and safety program. These improvements have resulted in fewer employee injuries, fewer OSHA citations and an exemplary safety image within the construction industry. Through the combined efforts of our staff and employees we have become more competitive and in turn, we have provided more jobs for all our employees.

As employees and subcontractors to Consigli Construction Management, you represent all of us in the workplace and we need your pro-active support to continue making safety improvements and continue expanding our market share. Therefore, we are asking all employees and subcontractors to read, understand and practice the enclosed Health and Safety principles and guidelines. This means routinely training employees, conducting weekly toolbox meetings, wearing appropriate personal protective equipment, using fall protection when necessary and practicing all other safety-related items listed in the Safety and Health Handbook. Even more importantly it means developing a safety-conscious attitude.

We take safety very seriously and we expect you to do the same. If you have any questions, call me or ask the Site Superintendent at your worksite.

Thank you,

SITE LOCATION

The construction site is located at West Point, New York 10996. The location for the project field office is currently at the Project jobsite (notifications of any changes will be provided). When determined, the field office will become the Emergency Operations Center (EOC).

EMERGENCY TYPE

The following situations are considered emergency response actions and should be handled in accordance with the procedures outlined in this plan.

- Serious Injury/Fatalities

- Fire/Explosion

- Structural Damage/Collapse

- Weather or Geological Event Classified as an Act of God

- Environmental Incident

- Traffic Disruption

- Utility Damage

- Illegal Activity

- Labor Problems

- Bomb Threats/Military Ordinance Unearthing

- Acts of Terrorism

When reporting an emergency, please provide the following:

• Your location, phone number, and name;

• The location of the incident (building name, floor and room number);

• Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

SEE APPENDICIES A, B & C OUTLINED IN THE LAST PAGES OF THIS PROGRAM. West Point Crisis Protocols are made part of this manual and shall be displayed on the Safety Bulletin Board on both the Site Office Trailer and within building project.

• The safest route to the incident

Crisis Response Protocol:

- Attend to the injured

- Immediately contact Dan Della-Guistina (Safety Director) (508)686-6008 Edwin Robinson (Safety Manager) (845)518-4897

- Post person at front gate, only allow access to emergency responders

- Record names/addresses of witnesses

- Do not allow media on site

- Refer all media inquiries to home office (See “Crisis Response Cards”)

A Consigli designated individual shall wait at the West Point Anderson Athletic Center Building entrance to escort Emergency Services personnel as they arrive.

**List of First Aid-CPR trained personnel will be compiled and posted in the project office and in this site specific Safety and Health Plan.**

The following is a list of the Chain of Command/Call Hierarchy on the project for establishing lines of succession during communication involving all emergencies.

Back– End of Emergency Response Plan

Emergency Contact Names and Numbers

1. First call: 911 Fire or police

2. CONSIGLI PM: John Stanforth (845)476-0189

3. CONSIGLI PE: Nolan Sherman (845)303-0988

4. CONSIGLI PX: Chad Danforth (845)663-4116

5. CORPORATE SAFETY: Edwin Robinson (845)518-4897

6. GEN. SUPERINTENDENT: Sean Hynes (845)902-8395

7. Corporate Safety Dirctor: Dan Della-Guistena (508)686-6008

Additional Contacts

West Point Military Police: Non-Emergency (845)938-3333

West Point Fire Department: Non-Emergency (845)938-4646

Back– End of Emergency Contact Names and Numbers

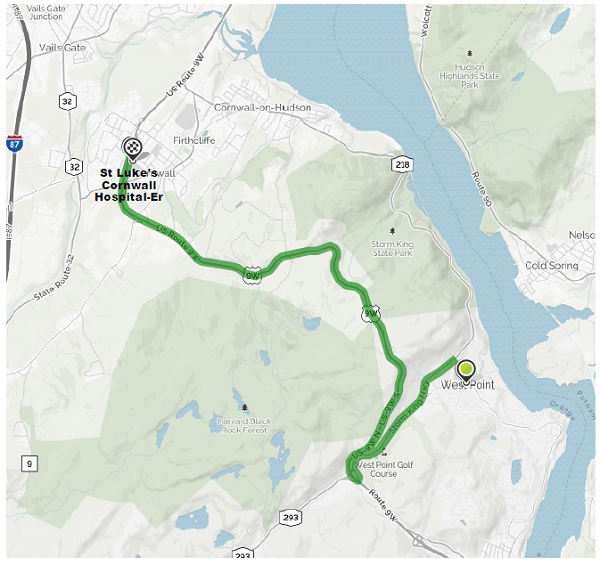

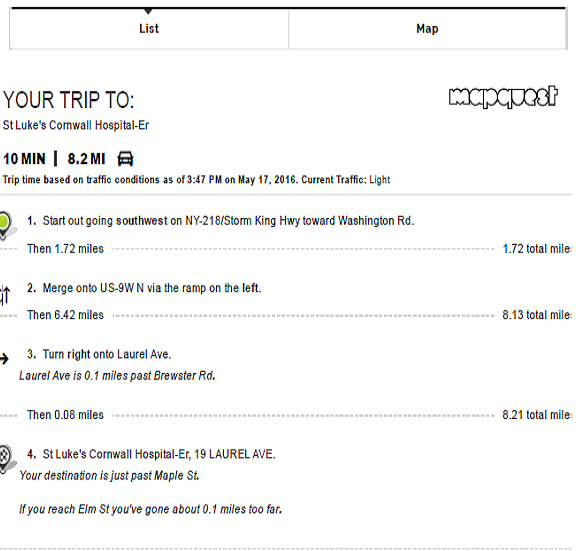

Medical Facilities

St. Luke’s Cornwall Hospital Non-Emergency (845)561-4400

70 Dubois St, Newburgh, NY 12550

In case of emergency a Consigli representative will be dispatched to the Main entrance of the building to meet the responding Emergency Personnel and advise the individual in charge of the location of any chemicals or hazardous substances that may be present on any of the floors. MSDS/SDS sheets will be readily available if needed by the West Point Fire Dept.

In the event of a serious injury requiring the assistance of Local EMS the injured worker will be kept as comfortable as possible. Emergency first aid if necessary will be administered. Under no circumstances will the injured person be moved unless the worker’s life is in danger because of fire or calamity. A worker will be assigned to meet the medical personnel at the above location to direct them to the location of incident.

In the event an evacuation is required all personnel at this job site will assemble next to the pedestrian walkway located in the back parking lot on Newbury Street. The foreman for each company will meet at that location and take a head count of their staff and report to the Consigli Superintendent. If for some reason a worker is unaccounted for, the fire department will be notified of the last location where the worker was observed.

Directions to St. Luke’s Cornwall Hospital

Back– End of Medical Facilities

Site Safety Plan

PURPOSE: The purpose of this Site Specific Safety and Health Program is to illustrate Consigli’s approach to identifying project specific hazards and controls and how said risk is managed through a comprehensive Safety and Health Program.

S.A.F.E.: Staying Accident Free Every Day is the Safety Mission that forms the very foundation of the Consigli Safety Culture. The S.A.F.E. mission, which is supported by technology, (Predictive Solutions internal auditing instrument which identifies and defines leading indicator related information); Leadership (Empowering our team members to assure safe projects); Humanization (Protect the ones you love by protecting yourself); Jobsite Gym (Morning warm-ups, stretch and flex); Training (Integrating sub-contractors into the Consigli Safety Culture); and Lean (nothing hit the ground), is the driving force behind Consigli’ s drive to our vision – ZERO. ZERO is the philosophy that all accidents are preventable and that no accident is acceptable. The S.A.F.E. mission is the guiding force to achieving the Consigli Safety Vision which is ZERO.

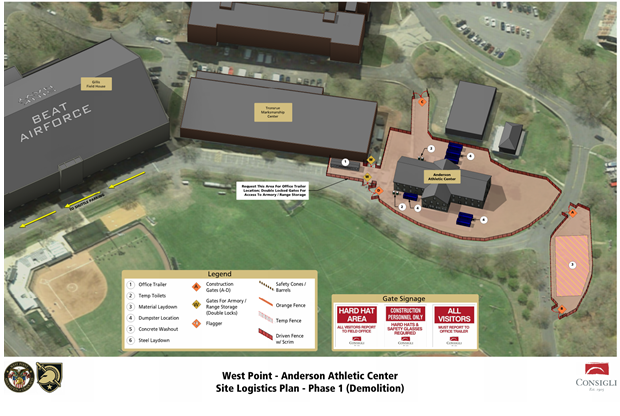

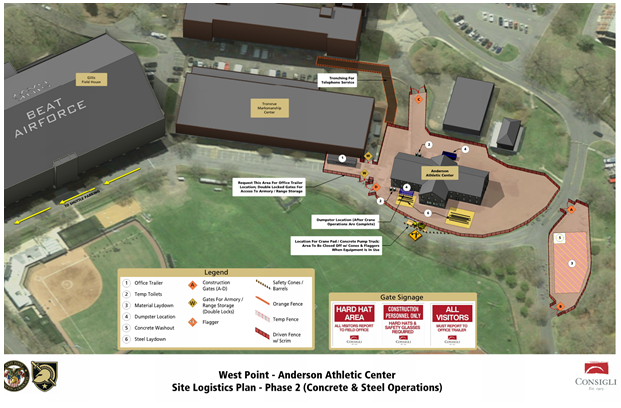

Logistics/Access/Traffic Management: Main construction access will be restricted to routes pre-determined by West Point and Consigli Construction Superintendent. All contractors will be responsible for adhering to Consigli Construction and West Point Academy restrictions and regulations in regards to driving, parking and delivering materials. Strict adherence to posted speed limits and parking locations is required. Pedestrians will be given the right of way at all times. Parking will be designated in pre-determined contractor parking locations and reviewed during orientation. Pedestrian access through the campus must be along posted walkways and sidewalks. No shortcuts!

- Gate A & B – Gate “A” & B (As per the logistics plan). Will be mainly designated as the Construction site Laydown area.

- Gate C – Gate “C” (As per logistics plan). Will be designated as an alternate use gate.

- Gate D – East side “Main Construction Gate/Access to site office area. Debris dumpsters and porta johns will also be staged in this area.

Designated work hours (any work outside these hours must have prior Consigli approval): All work shall take place during business hours, Monday – Friday 7:30am to 5:30pm, any work which may need to take place outside of these hours will need to be approved by the CONSIGLI Superintendent.

Services: Any compromises to West Point Anderson Athletic Center Project site during the work performed will be handled accordingly

- During weekly project meetings, if needed upcoming work that may compromise service or impact the public shall be talked about with Site Superintendent and scheduled for off shift if the group decides it will be needed.

- The on-site superintendent shall perform weekly inspections of all adjacent establishments and businesses for the duration of the project to ensure minimal construction impact.

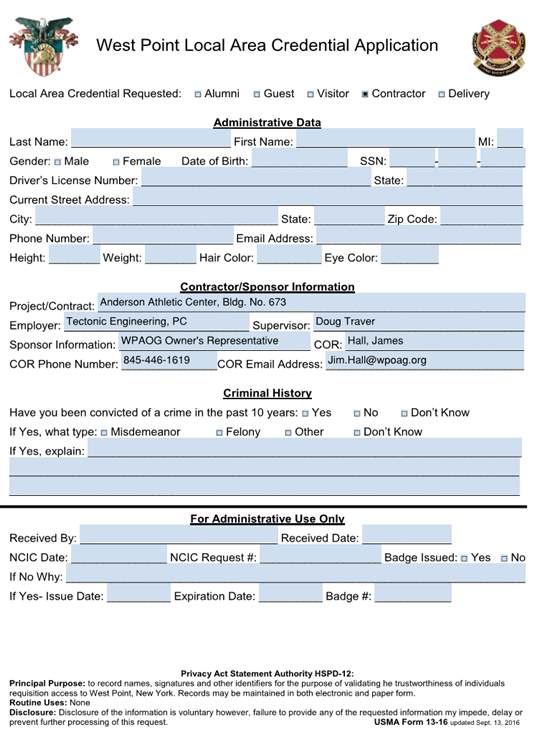

Badging Requirements: West Point access badges must be obtained by all identified personnel prior to working on this project. All workers will be required to fill out a “West Point Local Area Credential Application” at the Visitors Center at which time the West Point Police will perform a background check prior to approving an entry badge (See Below). Badges will issued by West Point Police and will be scanned and inspected daily at all entry gates. Badges shall be worn so they are visible at all times. All personnel will comply with West Point security requirements and posted campus laws.

Activity Safety Analysis (ASA)/Toolbox Talks: An ASA/JSA depending on level of hazard shall be conducted for each identifiable feature of work to be performed. The ASA/JSA shall be submitted to Consigli superintendent/supervisor. ASA/JSA shall be reviewed weekly, signed by all workers including their supervisor, with all involved personnel performing that particular task.

Subcontractors under their contract shall be responsible for drafting and reviewing all ASA/JSA’s with their workers each Monday as well as toolbox talks that address the work that they will be performing and that which is relative to safe work practices.

Demolition: Pre-work surveys

Live utilities will be running through the building prior to building scheduled demolition. It is for this reason that Consigli will require that all MEP subcontractors perform a pre-demolition survey to ensure that the work areas are made-safe for demolition work to commence.

From this survey, the competent person from each trade will relay back any unsafe conditions to the Consigli Superintendent. At no time shall demolition work commence without Consigli Superintendent having all documented “Make Safes” provided by the responsible MEP subcontractors that confirm the isolation of all utilities feeding the construction area.

Pre-Demolition Make Safe

Prior to the start of demo operations, the contractor preforming demo will confirm that all utilities leading into the area have been made safe. The subcontracted electrician will disconnect and lock out all electrical, the plumber will do the same with any plumbing lines, and the HVAC subcontractor will do the same on the HVAC piping and duct work. Lock out tag out will be reviewed during the pre-construction safety meetings to assure disconnect and responsibility for protection of existing utilities is safe for any construction activities to commence. Subcontractor coordination and completion of the safe work permit shall be through the Consigli Superintendent.

In spaces where some electrical or mechanical must remain live, a color coding system will be utilized for easy identification of live utilities that must stay active and utilities that must be removed. Any and all utilities spray painted (or otherwise marked) Red are not to be touched and are need to be protected during all operations. Utilities spray painted Green are to be removed as part of the selective demolition process only after lock-out/tag-out has been confirmed and utilities tested. If any utilities are unmarked, they shall be considered live until they are marked. Any existing walls shall be removed using hand tools until investigation shows what mechanical systems are present behind the wall. The demo contractor will be responsible for completing CCNY demo checklist prior to the start of any work in their target areas.

Lockout/Tagout, scheduling shutdowns : All mechanical, electrical, plumbing, etc. systems that require work to be performed on them shall be effectively LOTO to a de-energized state. These procedures shall follow in strict accordance with the OSHA requirements in 1910.147 – Control of Hazardous Energy, NFPA 70E, NFPA 99, etc. West Point Facilities may have procedures already established for this work. In every case, shutdowns of all types are required to be coordinated with the West Point Management team. At no time will work be performed on any system prior to this meeting taking place.

Demolition Scope

Shoring Requirements

- Provide all shoring of steel trusses as shown in drawings. Provide shoring from panel point down to grade as noted.

- Provide all shoring of timber trusses as required for removal of wood decking and portions of bottom chords as noted

- Provide all shoring of existing chimneys to remain as required

- Provide all shoring and lateral bracing of existing structure to facilitate removal of interior slabs and masonry bearing walls

- Confirm understanding of demolition sequencing which directly impacts the installation of all shoring and bracing required

- Provide 6 month rental for shoring

- Provide all engineering of shoring and bracing system as required. Provide engineered connection points for system within the building as required

- Sales tax on shoring system

Selective Demolition

- Remove existing concrete slab on grade and associated subbase

- Remove existing concrete ramp

- Remove existing masonry bearing walls

- Remove existing window and salvage for re-use

- Remove exterior masonry wall for new opening

- Remove existing wood framing

- Remove existing staircase and all associated components

- Remove existing elevated concrete slab

- Remove existing interior partition

- Remove existing non-structural wood framing members throughout attic space

- Remove existing wood decking and bottom chord of timber truss as required

- Remove existing door, frame and hardware

- Selectively remove 12″ of brick coursing below door sill

- Remove existing chimney up to 3rd level

- Remove existing door, frame, transom and hardware

- Remove existing non-structural wall partitions

- Remove existing wood guardrails

- Remove existing window for new mechanical louver

- Remove existing steel beams

- Remove existing steel columns

- Remove existing concrete wall along existing rubble foundation

- Remove existing mud slab throughout crawl space

- Drop, haul off and dispose of all MEP/FP items indicated to be removed. All cutting, capping and make-safe of these items shall be provided by others

- Provide all dumpsters as required to dispose of demolition debris

- Prior to the start of demolition, review with the Owner which items are to be salvaged or re-used

- Remove and relocate and store all existing equipment identified by the Owner

- Salvage light fixtures to be re-used and store per Owner’s instructions

- Salvage and store all fire extinguishers for re-use

- Protect all items indicated as existing to remain

Excavations: (CONSIGLI PROGRAM APPENDIX PP – EXCAVATION CHECKLIST)

Excavation/site work will incorporate extensive removal of existing utilities and is expected to take place within both the West Point Anderson Athletic Center as well as outside the controlled project site area. Excavations may not be limited to five feet in depth and may be open for a considerable length of time. All required permitting (if applicable) will be obtained before any excavating is to begin. If necessary, tabulated data/engineering for shoring and shielding systems will be obtained and available on site at all times when in use. All excavations will be inspected by a competent person on a daily basis. Written excavation inspections will be done if the excavation exceeds 5’. Any and all roadway work (If applicable), shall be performed with all Army Corp permit requirements in place and closures pre-planned with West Point.

- Dig Safe Notification – dig safe number (If needed) will be obtained and posted in the site office.

- Copies of shoring engineering and tabulated data sheets for all trench boxes or other shoring/shielding systems brought on site will be provided to Consigli and be kept in construction office.

- Designated flagman will be utilized during all work that directly or may indirectly effect the public and West Point Campus staff.

**Review Chapter 19 of Consigli Construction Safety & Health Program for more detail**

Site Work Scope

- Removal of existing manholes & catch basins

- Remove existing storm drainage structure and associated piping – C100

- Cut, cap, & restrain exg water and fire service piping – C100 – west side of building

- Removal of existing water and fire service piping – C100 – west side of building

- Cut, cap, & remove existing gas service piping – C100 – south side of building

- Remove existing storm pipe – C100 – south side of building

- Cut, cap & abandon steam & condensate piping – C100 – east side of building

- Remove existing abandoned steam piping from cut to building – C100

- Remove & replace storm pipe in southeast corner of building as shown – C100

- Remove section of existing electrical ductbank – C100 – north side of building

- Demolition of existing concrete walkway – L101.1

- Removal of existing vegetation around foundation – (2) redbuds to remain – DIV 32

- Sawcut existing pavement and remove as shown

- Removal of all concrete stairs, eastern retaining wall, & chain link fence east side of building

- Demolition of existing walkway or underground utilities – east side of building

- Sawcut access drive for installation of retractable bollards and associated utilities – south side of building.

- Remove portion of concrete walkway & chain link fence (to be reused) – south side of building

- Removal of all vegetation on slop between Andersen Athletic Center & Building #675 as noted only

- Removal of existing walkways – west side of building

- Removal of all curbing, pavement, & concrete walkways – north side of building

- Removal of existing electrical conduit – ADD #2

- Coordinate all utility shut offs with utility company and owner prior to construction phasing

- Protect all existing utilities to remain

- Provide all soil erosion, sediment control measures, & tree protection fencing prior to start of site clearing

- Provide a concrete washout area

- Protection of all existing trees, vegetation, plants, shrubbery, etc that are to remain

- Disposal of all materials not being salvaged or reused as specified

- Excavate and backfill for all new concrete sidewalks

- Excavate and backfill for all new concrete retaining walls

- Excavate and backfill for all new concrete curbs

- Excavate and backfill for all new asphalt paving

- Excavate and backfill for all equipment pads & bases

- Excavate and backfill for all site stairs and foundations

- Excavate and backfill for all bollards

- Trench and backfill for all new underground utilities

- Trench and backfill for all existing underground utilities to be removed

- Excavate and backfill for all new sanitary manholes, catch basins, & patio drains

- Excavate subsurface materials & prep to receive underslab utilities – Note 2 A051

- Excavate and backfill for all new footings, foundations, shearwalls, SOG, & piers

- Excavate for underpinning shall be included (underpinning by Concrete SC)

- Excavate and backfill for all new irrigation systems

- Provide all cuts and fills as required to achieve proposed grades

- Acknowledgement of multiple phases for interior excavation and backfilling work -2/S003

- Coordinate all utility shut offs with utility company and owner prior to construction phasing

- Confirm acknowledgement and compliance with geotechnical report located in Division 01 – supplemental information

- Provide all equipment necessary to complete own scope of work

- Provide all extra materials as specified

Fall Protection: All workers exposed to a fall of 6′ or greater shall be protected by guardrails safety nets or personnel fall arrest systems. this include, but is not limited to, interior/exterior structural steel work, scaffold erection and dismantling for West Point Anderson Athletic Center, overhand brick laying and pre-cast concrete related work. Holes greater than 2” will be covered with acceptable material (3/4 plywood ½ steel) which will be secured and marked hole and capable of supporting 2x the intended load (cover must be able to withstand 2x times the intended axle load). Covers will stay in place until the hole/penetration has been filled with duct or Pipe riser which extends above the deck. Building perimeters (to be protected with cable guard rail system with turnbuckles to be installed for all straight runs and any straight run over 100 feet.

Before any work is to begin on West Point Anderson Athletic Center it must be determined what method of fall protection will be implemented all workers working on the opera hall upper levels and exposed to a fall greater than 6 feet will have fall protection 100%of the time spent in this location.

Workers on a walking working level with an uncontrolled leading edge must be protected by Personal Fall Arrest System (PFAS) or Guardrail systems as flagging is prohibited and can only be utilized during roofing work. All access/egress points to attic or upper level areas to which workers must perform work shall be made safe with guardrail systems. All ladder access/egress shall extend 3’ above work area walking surface and be secure from displacement.

All material will need to be kept a minimum of 6’ from all leading edges, any materials that may be displaced off upper floors shall be removed or relocated.

The use of safety Monitors is not allowed!!!

**Review Chapter 13 of Consigli Construction Safety & Health Program for more detail**

Work on Ladders: All work on step ladders/straight ladders will be done correctly per manufacturer’s recommendations. Any worker who is on a step/straight ladder and could be exposed to a fall greater than the height of their work on the ladder will be required to install a form of fall protection. Step ladders will not be used as a form of access to a walking /working level. Only ladders with a rating Type 1A or 1AA will be allowed on Consigli projects.

All ladders shall be inspected prior to each shift. All ladders found defective or damaged shall be removed from service immediately.

Scaffold and elevated work platforms: (CONSIGLI PROGRAM APPENDIX EE – SCAFFOLD CHECKLIST)

All Scaffold deck systems will be engineered and designed to allow access/work for all elevated work areas. Systems will completely cover the entire work area thereby allowing for any and all building structural work. All scaffolds supported frames, pipe and staging platforms will be inspected daily before each shift by a competent person designated by each individual contractor who will be using it, which will be documented on Inspection tags located at the stair tower to each section.

A scaffold checklist guide will be provided by Consigli to each sub-contractors designated persons to aid them with their daily inspection. All contractors who will be erecting scaffold will provide Consigli with certification/Qualification of scaffold erection training as well as an erection/dismantling plan. Fall protection is required 100% during erection/dismantling. Overhead protection will be provided for all access points at any buildings which are located under any form of scaffolding. Fall protection is required at 6’ on all scaffolds, on mobile scaffold fall protection is required at 4’. Mobil staging with a work platform with a height to base ratio greater than two to one will require outriggers. All scaffolding that is procured by Consigli and is over 15’ in height will require that the Consigli Safety Department review the scaffold prior to it being turned over for use by tradesmen.

** Review chapter 14 of Consigli Construction Safety & Health Program for additional details.**

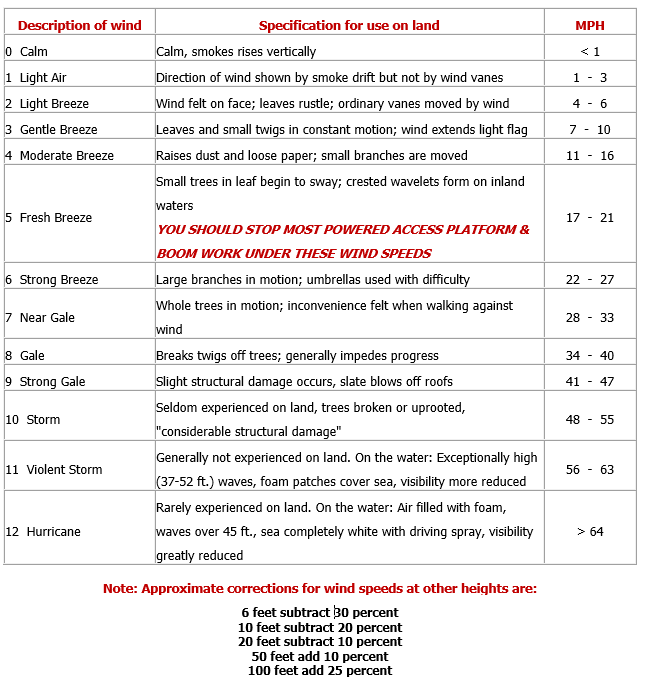

Beaufort Scale of Wind Force

An aerial lift can be very dangerous. Operating an aerial lift when it’s windy can be a deadly mistake. You must be able to determine if the wind force is too dangerous to safely operate your aerial lift. Below is a chart to help you determine the wind speed and if you should or should not be working. The Beaufort Scale of Wind Force is accepted internationally and used in communicating weather conditions. It consists of number 0 – 12, each representing a certain strength or velocity Corp of wind at 33 feet (10m) above ground or in the open. This should be used to assess when it is safe to operate your powered access equipment.

Note: Approximate corrections for wind speeds at other heights are:

6 feet subtract 30 percent 10 feet subtract 20 percent 20 feet subtract 10 percent 50 feet add 10 percent 100 feet add 25 percent

Aerial/Scissor Lifts: (CONSIGLI PROGRAM APPENDIX HH – SCISSOR LIFT INSPECTION FORM, APPENDIX JJ – AERIAL LIFT INSPECTION FORM)

Aerial lifts may be required for any exterior restoration work if required. Prior to use the area and ground conditions, in the intended work area, will be inspected for overhead power lines, sink holes, covers, or any other unsafe conditions which cause an unsafe incident.

Aerial lift platforms will be inspected daily before each shift by a competent person designated. All who will be performing work from an aerial lift will show documented proof of training prior to using the lift. Steel plates or equipment mats will be placed on the ground above any utility/ underground structures if there will be Aerial lifts operating directly over them.All aerial lift work on Campus roadways may require additional flag persons to control traffic and protect the public. Such use of flag person shall be evaluated prior to commencement of work and be added to the subcontractors JSA/ASA for all workers to review. ALL WORKERS SHALL UTILIZE FALL PROTECTION SYSTEMS WHILE OPERATING AERIAL LIFTS AT ALL TIMES.

Wind shall be a major contributing factor to safe operation of aerial lifts by workers. The “Beaufort Scale of Wind Force” (Chart Above this Paragraph) shall be the deciding control measure for safe operation during wind gusts and sustained winds. The below chart shall be reviewed and implemented when winds exceeding the levels outlined are experienced during aerial lift operations. No supervisor or worker shall allow any aerial lift operation where sustained winds or wind gusts exceed the below measurements.

HEAVY EQUIPMENT USE: (CONSIGLI PROGRAM APPENDIX UU – POWERED INDUSTRIAL TRUCK CHECKLIST)

All heavy equipment including Powered Industrial Vehicles (Rough Terrain Forklifts)

- All operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the State of Massachusetts.

- All safety devices and warning alarms must be in good working order and all leaks are to be repaired immediately.

- All equipment will be used in accordance with the manufacturer’s recommendations for safe usage and have its operators manual as well as an extinguisher with it at all times.

- Subcontractors who will have equipment on site will be responsible for having a spill kit available at all times.

- All heavy equipment shall be maintained in a safe manner and shall be regularly inspected for operational deficiencies and damage caused during construction use.

- All required Powered Industrial Truck inspection shall be documented using the Powered Industrial Vehicle Inspection Form (APPENDIX UU) or approved equivalent.

** Please review chapter 24 of Consigli’s Safety and Health Program for additional details**

Chemical and Materials: All Materials and chemicals used on-site will have MSDS/SDS sheets provided before being brought onsite.

- MSDS/SDS sheets on file in Consigli Construction’s Site Safety Plan

- All MSDS/SDS sheets shall be readily accessible.

** Review chapter 20 of Consigli Construction Safety & Health Program for additional details.**

Fire Protection: (CONSIGLI PROGRAM APPENDIX OO – HOT WORK PERMIT)

Hot-work is anticipated. Any and all hot-work requires the CONSIGLI hot work permit program to be implemented. This will be coordinated through the CONSIGLI Superintendent, as well as West Point Fire Department (If needed). Any hot work will stop one hour before the regular end of the day work stoppage. Flammables will not be stored inside the building or left overnight on the scaffold or in the building. All combustible or flammable materials will be stored in an appropriately rated lockable cabinet located no closer than 50 feet from the nearest structure. Fire extinguishers will be provided for every 1500 square feet. They will be installed on job made stands and conspicuously located throughout. They will be part of the daily inspection with extinguisher log completed monthly. Storage of any acetylene cylinders will be done in a secure and upright area, with good ventilation. This will be a strict no smoking project. All penetrations leading outside of the construction area will be fire stopped using approved fire rated material prior to the end of each shift. Fire blankets shall be utilized for all torch cutting, welding and any operation that produces significant spark during work operations. All subcontractors performing Hot Work shall supply their own fire extinguisher for the work performed and have it readily available at the location of work. All Hot-Work Permits issued by CONSIGLI shall be readily posted near the work area for review by the safety department’s safety manager.

**Review Chapter 17 of Consigli Construction Safety & Health Program for more detail.**

Electrical: All electrical tools, cords and equipment must be in good working order. To that end, all electrical tools and components must be visually checked on a daily basis. Any tools with damaged cords or damaged cords must be taken out service… All cords must be equipped with a ground pin, flat three wire cords are not allowed. SJO and SJT or other similarly rated cords only shall be used. The electrician will be responsible for all temp power and any temp lighting that may be needed. They will coordinate all lock out tag out procedures. All temporary power for the project will be installed on protected and dedicated circuits with 100% GFCI protection. GFCI will be tested by the electric contractor weekly to assure proper function with a log book filed with CONSIGLI monthly. No live electrical work will be conducted. No live electrical work will be conducted per NFPA 70E.

Subcontractor shall, where feasible, elevate all electrical extension cords, hoses or cables – removing them from all walking/working surfaces.

Subcontractors shall provide their own task lighting required to complete their scope of work. Temporary construction lighting/power complying with OSHA standards shall be provided by electrical subcontractor.

**Review Chapter 26 of Consigli Construction Safety & Health Program for more detail**

Utility Exposures: Any overhead power lines will be located and identified prior to use of any equipment which may come in to contact with them… All sidewalks will be protected if equipment is to be driven over them. All street work shall have a separate written plan that accounts for protection of the public.

Crane: There will be cranes on site at various times in order to load/unload material, place roof top HVAC units and provide installation of structural components. It is anticipated that either a 70 or 90 ton crane will be utilized. All cranes will require independent annual 3rd party inspections and will be utilized for operation only after detailed lift plans are submitted.

It is anticipated that these cranes will be hydraulic. In the event that a lattice boom crane is utilized, then the crane must get an on-site 3rd party inspection once the crane is assembled, prior to operation.

There is a requirement to assure that certified riggers, signalmen, and crane assemblymen are utilized. All picks are to be done by a licensed operator. As previously mentioned, a detailed pick plan will be required to assure that no picks are critical in nature. Critical picks are defined as those involving 2 cranes lifting simultaneously, a pick that is over 75% of capacity, a pick that involves the lifting of a man basket, or any other lift that is deemed to involve special conditions. Location and set up will be reviewed with crane operator prior to set up and pick. All lifting operations will require that the operator and any involved contractors follow the steps listed below as well as in Consigli Crane Safety policy.

- All Hoisting equipment will have an up to date 3rd party inspection certificate with the equipment which will be copied and filed in the office trailer.

- All lattice boom cranes will have an independent 3rd party inspection completed each time one is set up on the project, after assembly and prior to operation.

- All equipment operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the NYS Department of Labor.

- All underground vaults and existing utilities will be marked before as well as before any crane is set up.

- Documented rigging equipment inspections.

- Documented daily crane inspections filed with Consigli weekly.

- Documented rigger and hand signalman training will be provided.

** Review chapter 24 of Consigli Construction Safety & Health Program for additional details.**

Equipment issues: All operators will be required to have in their possession all appropriate licensing and training as required by OSHA and the NYS Department of Labor.

All safety devices and warning alarms must be in good working order and all leaks are to be repaired immediately. All equipment will be used in accordance with the manufacturer’s recommendations for safe usage and have its operators manual as well as an extinguisher with it at all times. Subcontractors who will have equipment on site will be responsible for having a spill kit available at all times. Superintendent shall designate the location of parked equipment following the end of each work day.

**Review chapter 24 of Consigli Construction Safety & Health Program for additional details**

STRUCTURAL STEEL WORK (Related Consigli Program Appendix LL – Approval to Begin Steel Erecting, Appendix MM – Custody of Fall Protection)

Steel erectors must submit to the Consigli Superintendent a site-specific steel erection plan written by a qualified person two weeks prior to commencing work. The plan shall contain minimally:

Site Layout

- Sequence of erection

- Deliveries

- Staging & Storage

- Path of overhead loads

- Lift Plan/Crane Set-up

- Fall protection procedures (fall protection required at 6 feet for all operations)

- Post fall protection plan

- Training documentation

- Qualified and Competent person(s). Including Rigger/Signalperson

- Critical Lifts

It shall be assured that all applicable constructed concrete Footings, Piers, Walls, and/or mortar in Masonry Piers and walls are in accordance with ASTM standard test method and has reached 75% (Percent) of its intended minimum compression design strength and signed off by a qualified person. The Engineers test results shall be documented and sent to the steel erector prior to structural steel erection commencing utilizing the “Approval to Begin Steel Erection Form” (APPENDIX LL)

Erecting requirements

- Each employee engaged in a steel erection activity that is on a walking/working surface 6 feet or greater above a lower level shall be protected from falling by use of guardrail, safety net or personnel fall protection system. When personal fall protection systems cannot be attached overhead, they must be of the appropriate type to account for 12’ free fall requirements as detailed in ANSI Z359.

- Welded alloy steel chain slings shall have permanently affixed durable identification stating size, grade, rated capacity, and sling manufacturer.

- Perimeter columns should have holes at 45 inches above the structural slab to install 3/8 inch air craft grade cable or if using other devices then it must meet the fall protection requirements (200 pounds in an outward and downward direction) or the anchoring point requirements (5000 pounds per person tying off to it). All wire rope shall be secured with at least three (3) Crosby Clips. (APPENDIX MM)

- Steel subcontractor shall on all perimeter cable guard railings install turnbuckles on each straight run. Subcontractor is prohibited from installing cable guard railing round column corners.

- All angle steel upright corner stanchions for cable guard railing shall have support steel angle welded at minimum 75% the height of the vertical stanchion to ensure structural integrity during cable guardrail adjustment and maintenance.

** Please review chapter 16 of Consigli’s Safety and Health Program for additional details **

Confined Space: A written plan will be needed to work in any tanks/vaults and crawl spaces during this project which have been designated permit confined spaces by CONSIGLI, this plan must include air monitoring. All certifications of training as well as field monitor calibration shall be supplied in the plan prior to commencement of work. Preconstruction meeting shall be scheduled prior to any confined space work to review the plan and make any corrections to the plan prior to such work.

**Review chapter 21 of Consigli Construction Safety & Health Program for additional details.**

Designated First Aid Plan: All injuries no matter how minor must be reported to Consigli Superintendent immediately. The superintendent will then report all injuries to the CONSIGLI Safety Manager Edwin Robinson. A fully stocked first aid kit and blood borne pathogens kit shall be maintained on the project site. Only properly trained personnel will administer first aid. Consigli Construction Management shall follow Site Safety Plan for first Aid. Report any incidents to the Safety Manager.

IMPORTANT: All eyewash stations shall be maintained in a clean condition throughout the projects scheduled completion date.

**Review chapter 1 and 27 of Consigli Construction Safety & Health Program for additional details. **

Evacuation Plan (RACE, and Routes of Egress): Please refer to the Evacuation Plans attached. All Consigli employees and subcontractors shall attend the Project Safety Orientation. Consigli Construction’s Project Superintendent will conduct a safety orientation talk to each employee and subcontractor to site specific fire safety protocols.

Evacuation/Muster plan shall be posted in the site office as a means of ensuring all workers are made aware of the location of any emergency evacuation. The superintendent shall provide an overview of the emergency evacuation plan at the time of the site specific orientation with all workers.

Emergency Management Response: In the event of an Emergency the construction workers shall leave all 3 of the building immediately. Point of assembly/muster shall be located East Parking lot located on the south side of Plaza Road. In the Event of a DISASTER, the Superintendent or Safety Manager shall instruct the construction workers to leave the site or remain in place and await further instruction. The following steps should be taken in the event of an emergency;

When reporting an emergency, please provide the following:

• Your location (West Point, United States Military Academy, West Point NY) phone number, and name;

• The location of the incident (building name, floor and room number);

• Nature and extent of the incident (injury, accident, spill, smoke/fire, damage, etc.);

• The name and amount of the material spilled (if applicable); and

• The safest route to the incident site (if applicable).

**Review chapter 8 of Consigli Construction Safety & Health Program for additional details.**

Minimum Site Safety Requirement: All Consigli workers, and any subcontractors, shall have, at a minimum, an OSHA 10 Hour Construction Safety Outreach training certificate and shall provide documentation of training. All forklift operators, scissor lift and aerial lift operators shall also possess a copy of training and certification.

All subcontractor workers physically present on the jobsite may be subject to a CORI (Criminal Offender Record Information) background check. All workers will be required to display a project specific badge, provided by Consigli. Badge replacement costs (due to loss, theft or similar) shall be the responsibility of the subcontractors

Personnel Protective Equipment (PPE): All Consigli and subcontractor workers will wear hard hats and safety glasses 100% of the time on site. All Consigli personnel performing work with their hands shall be required to wear gloves that are appropriate to the task. When not performing actual work with their hands workers will be required to have them available for immediate use. Face shields will be required for all personnel who are performing overhead work, using metal chop saw or any type of metal grinding. All welders will be required to have hard hats with integral welding shields.

PPE Training: Necessity, use, limitations, care and maintenance of all provided PPE by a subcontractor supervisor will be conducted upon issue. Said training is to be documented as part of the subcontractors toolbox talk meeting process. Retraining of employees by the subcontractor supervisor shall be conducted anytime site conditions change, PPE requirements change, or employee demonstrates improper use or lack of knowledge.

Personal protective equipment, which has been changed in any manner so as to reduce its effectiveness, shall be repossessed, repaired or destroyed. Personal protective equipment worn or used previously by a worker shall not be issued to another employee until the article has been cleaned and sterilized.

IMPORTANT NOTE: Personnel protective equipment for visitors shall include hard hats, high visibility vest and safety glasses as required.

Restricted Areas: Contractors are prohibited from entering any adjacent areas of the West Point worksite unless work has been previously authorized and scheduled by the site superintendent. It is important that workers do not park in/in front of adjacent driveways or block business and residential access driveways during construction. All workers will try to limit their impact on surrounding areas.

Materials Management/Lean: Materials management, getting materials into and out of the project, will be done through existing service doorways and any available loading docks if available. Getting materials into and out of the project will be a challenge that needs to be adequately planned. All deliveries are to be scheduled with the Consigli Superintendent. A comprehensive Activity Safety Analysis shall be done on all materials that will be hoisted and placed into the building. No materials shall be delivered to the site earlier than 3 days before said materials are to be installed/put into place. If materials have to be delivered before that 3 day time period, subcontractor to get prior approval from Consigli Superintendent. Because of this, notification / scheduling is required for all deliveries to the site. Subcontractors must notify Contractor at least 24 hours in advance.

Contractor has the right to refuse any deliveries not properly scheduled or due to logistical constraints as necessary. Attention must be paid to structural analysis in regards to loading existing floors with material and equipment.

All subcontractors’ delivered materials shall be placed on wheeled carts, wheeled wracks or in wheeled bins so as to necessitate easy relocation in the event materials need to be moved. Materials/tools can be delivered and stored on pallets only if pallet jacks are delivered simultaneously with said delivery to provide for ready mobility.

Back– End of Site Safety Plan

Environmental Emergency Contact and Management Response

Consigli identified Emergency Response Subcontractor;

Name: Quality Environmental Solutions and Technologies (Quest) # (845)298-6031

1376 Route 9 Wappingers, NY 12590

Silica: Engineering/Work Practice Controls

Where applicable, Consigli Superintendents shall ensure that all related construction activities with potential for Silica exposure will be consistent with OSHA’s Construction Standard Table 1 (APPENDIX DDD). To ensure the highest level of protection for workers on all Consigli projects, engineering and work practice controls, including administrative controls, shall be implemented to reduce and maintain employee exposure to silica at or below the PEL, to the extent that such controls are feasible.

To achieve this level of protection, Consigli Superintendents and Subcontractors shall, at a minimum; Provide a detailed Job Safety Analysis (JSA) outlining all potential silica hazards and required control measures.

- If vacuuming is required, specialized vacuums with HEPA filtration are required. Methods to use and empty vacuums in a manner that minimizes the reentry of silica into the workplace shall be described and used.

- Ensure respiratory protection is selected based on guidance in 1926.1153 Table 1 or based on a Certified Industrial Hygienist’s or competent person’s assessment of the potential airborne exposure.

- Ensure that compressed air is NEVER used to remove silica from any surface.

Utilize dust collection tool systems and equipment outlined in Table 1 Maintain all surfaces as free as possible from accumulations of silica. Select methods for cleaning surfaces and floors that minimize the likelihood of silica becoming airborne.

- Ensure employees do not leave the workplace wearing any required protective clothing or equipment without HEPA vacuum removal of visible dust

Competent Person Requirements: All subcontractor employers shall identify a competent person to inspect and manage all activities with potential airborne silica exposure. Subcontractors working on projects within the scope of this Program shall appoint a competent person capable of managing and executing the duties described herein. The competent person must have training in the inspection of work areas and equipment and in the determination of safe working conditions. This person shall have a working knowledge of the 1926.1153 standards, shall be capable of identifying airborne silica hazards, shall determine the need for initial and additional exposure monitoring, shall recommend and implement engineering and work practice controls as outlined in Table 1, shall establish levels of PPE, and shall have the authority to take action to eliminate hazards and correct incidences of noncompliance.

IAQ (indoor air quality): During construction indoor air quality may need to be sampled to ensure that adjoin areas have not been contaminated during construction. The air may be tested for typical indicators such as but not limited to Temperature, Humidity, Carbon Monoxide, Carbon Dioxide and VOC’s. All testing will be done in accordance with a written IAQ plan written by a Certified Industrial Hygienist.

Asbestos: A Hazardous Materials report shall be prepared by the owner (Northwell Health) and all hazardous material will be abated prior to work commencing in affected areas.

This does not mean that asbestos could not still be found in other areas, caution must be used when working and if any workers identify any potentially hazardous substances then they should stop and notify their supervisor immediately. All identified asbestos will be fully abated by a licensed and regulated asbestos abatement contractor under a formal plan to be written, submitted and in accordance with the NYSDOL.

IT IS THE RESPONSIBILITY OF ALL SUBCONTRACTOR FOREMEN TO REVIEW THE HAZOUDOS MATERIAL REPORT & CORRESPONDING ABATEMENT REPORT WITH THEIR WORKERS. A copy of the hazardous Material/abatement report will be on site at all times and available to anyone request it.

Due to the fact that some asbestos may remain in place and not be abated during construction all workers will need to have at a minimum Asbestos awareness training.

All work and disposal will be done in compliance with state and federal regulations and standards

Lead: Not expected. Workers who will need to perform work on painted surfaces may need to disturb lead in paint by drilling, sawing, demo, fastening, or carpentry. In doing so they will use saws, drills, screw guns, impact wrenches, reciprocating saws, hand wrenches, ads, crowbars, hammers, and other hand tools. Consigli Construction does possess historical data to show that drilling, sawing, light demo, installation of hangers, hanging sheetrock, fastening, and carpentry do not put the employee above the action level. Despite this additional monitoring will be done. An exposure assessment will be done by all subcontractors for all task prior to when the full scale of this work is to take place. This does not mean that lead could not still be found in other areas, caution must be used when working and if any workers identify any potentially hazardous substances then they should stop and notify their supervisor immediately. All workers on this must have completed Lead Awareness training prior to starting on this project. Hand wash stations will be provided to ensure proper hygiene during the project. An exposure assessment will also be done for any task which will disturb any lead containing material.

Mold: Mold issues are not anticipated to be prevalent on this project, however if mold is discovered Consigli’s mold remediation policy will be implemented and followed.

**Review chapter 22 of Consigli Construction Safety & Health Program for additional details**

Noise: Noise exposure will be a concern so all operations must be coordinated with the Consigli Superintendent to limit any excess noise impact on the surrounding areas. All activities which may cause load noise will be restricted as needed so as to limit the impact on Guest/Members.

All subcontractors shall comply with any applicable local ordinances regarding noise control. All subcontractors shall heed noise limits as required and directed by Consigli, and adjust work accordingly.

All subcontractors will be required to have and follow a written hearing conservation program for work that generates noise levels greater than 85dba.

**Review chapter 29 of Consigli Construction Safety & Health Program for additional details**

Exposure to the Anderson Athletic, Staff and Residents: During all phases of construction pedestrian walkways around the project will be open and occupied. Some areas of project will be opened for construction at different times. Any pedestrian walkway under any type of scaffold or overhead hazard will be provided with overhead protection. At no time is any worker allowed to enter any of the adjacent buildings. Non fraternization with staff, members and Guest will be stressed with all subcontractor personnel during orientations.

Additional Controls: Prior to start of any work, all personnel involved in the project, including project managers must be:

- Trained and orientated by Consigli Construction. Stickers will be issued and displayed on hard hats

Planning: The project team will meet with the staff before the project start to review any site specific safety and health requirements. The project team shall be an integrated mix of owner, architect, engineer and Consigli Construction personnel. If, after reviewing programs and meeting with the individuals, the team is satisfied with the risk control direction, personnel will be permitted to begin work.

OSHA Reporting Requirements : All OSHA related reporting requirements shall be coordinated through the Director of Safety. OSHA has outlined basic mandated reporting requirements under section 1904 addressing all of the following Accidents;

- Within 8 hours for any job related fatality

- Within 24 hrs. after the in-patient hospitalization of 1 or more employees within

24 hrs. Of Employee’s amputation or loss of an eye

Loss Exposures and Controls: All individuals working on this project will go through a comprehensive Safety Orientation which will cover all company safety rules regulations and procedures as well as communicating any West Point Anderson Athletic Center specific requirements.

Fraternization between construction employees and project owners, West Point Anderson Athletic Center staff, public or Anderson Athletic will not be permitted.

Loud and profane language or clothing with offensive language will not be allowed on the jobsite. Extra efforts must be made to keep noise to a minimum.

All subcontractors will be required to supply a written Safety and Health program that outlines their company’s commitment to the safety of their workers. Consigli’s Safety Department will review the subcontractors plan at the time of the preconstruction meeting.

Back– End of Environmental Emergency Contact and Management Response